JeepParts

My Garage

My Account

Cart

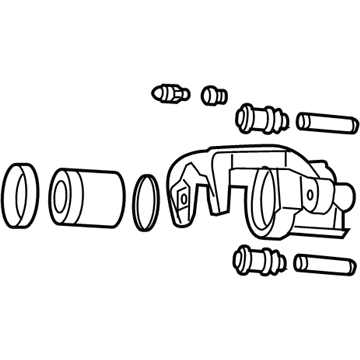

OEM 2006 Jeep Commander Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Brake Calipers found

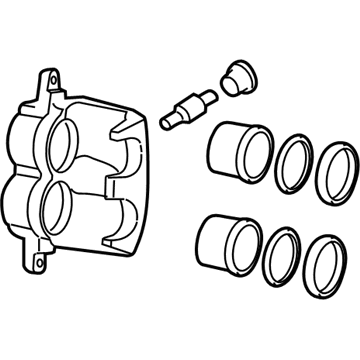

2006 Jeep Commander Caliper Assembly, Rear Driver Side Part Number: 5143703AC

$123.14 MSRP: $184.00You Save: $60.86 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Brake Caliper; Caliper

- Position: Rear Driver Side

- Replaces: 5143703AA, 5143703AB

- Item Weight: 5.30 Pounds

- Item Dimensions: 6.9 x 5.4 x 3.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143703AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Jeep Commander Caliper Assembly Part Number: 5143702AB

$89.90 MSRP: $132.00You Save: $42.10 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Brake Caliper; Caliper; Caliper Assembly Disc Brake Rear

- Replaced by: 5143702AC

- Item Weight: 6.20 Pounds

- Item Dimensions: 6.9 x 5.6 x 3.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143702AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

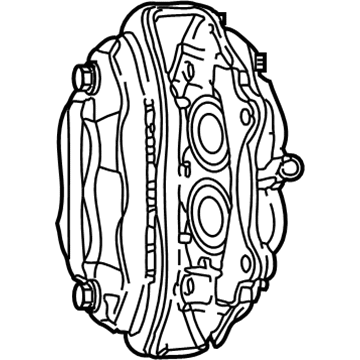

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Brake Caliper; Caliper

- Position: Front Driver Side

- Replaces: 5143693AB, 5143693AA

- Item Weight: 11.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143693AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Right; Brake Caliper; Caliper

- Position: Front Passenger Side

- Replaces: 5143692AA, 5143692AB

- Item Weight: 11.70 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143692AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Brake Caliper

- Position: Rear Passenger Side

- Replaces: 5143702AB, 5143702AA

- Item Weight: 5.10 Pounds

- Item Dimensions: 7.1 x 5.5 x 3.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143702AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Jeep Commander Brake Caliper Parts and Q&A

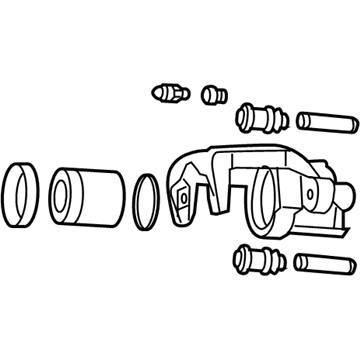

- Q: How to Service and Repair a Brake Caliper on 2006 Jeep Commander?A: You should start by raising and supporting the vehicle and after that, remove the rear wheel and tire assembly. Using a clean suction gun, suck out a bit of fluid from the master cylinder reservoir and use a pry to pull the caliper piston over. First, extract the brake hose banjo bolt connected to the brake caliper, remove the brake side washers, then unscrew the slide pins and finally pull the caliper and rotten brake pads away from the anchor. pump the brake pedal to drain the fluid and after that, clamp a block of wood between the pistons to protect them during removal. Use short, low pressure bursts of air through the port on the brake line hose for the caliper to remove piston one carefully, making sure not to keep the pressure on for a long time. When you've removed the first piston, make sure the empty bore is covered using a C-clamp and then use air to pull out the second piston. Very gently work the piston dust boots and seals loose, preventing any scratches on the piston bore. Extricate the caliper mounting bolt bushings from the boot seals and remove the boot seals from the caliper and finally remove the bleed screw from the caliper. All caliper parts should be cleaned with brake fluid or brake cleaner, not petrol or similar substances that could destroy the piston and seal. Check for damage or wear on the piston and change it if required, always using a replacement that matches the original in every way. If you see just minor marks in the bore, give it a light polish with a brake hone. In case the bore is severely wrecked or polishing widens the bore by more than 0.025 mm, change the caliper instead. During assembly, clean and dry the area, fill the pistons, bores and seals with clean brake fluid and insert the new piston seals in the caliper bores. Smear the edge of the new boot with silicone grease, slide it onto the piston and make sure it is in position. Set the piston in the caliper bore, use Handle C-4171 to push it down and position the dust boot with Installer. Lubricate each piston, dust boot and the mounting bolt bushings, boot seals and bores with Mopar brake grease or Dow Corning G407 grease. Fit the boot seals into the holes on the caliper, adjust their position in the center and attach the mounting bolt bushings, so the seal lip is edged into place. Bring the caliper bleed screw down again, place the brake pads in the caliper assembly, sprinkle oil on the slide and bushing holes and hang the caliper onto the anchor bolt. Wrap the brake hose so it doesn't twist and tighten all caliper slide pin bolts to 25 Nm, but DO NOT tighten the fitting bolt yet. Place a clean gasket washer between the brake hose and the caliper and set the banjo bolt at 31 Nm. After that, bleed the brake system, install the wheel and tire assemblies, take off the jack or lift and lower the car.