JeepParts

My Garage

My Account

Cart

OEM 2006 Jeep Liberty A/C Compressor

Air Conditioning Compressor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 A/C Compressors found

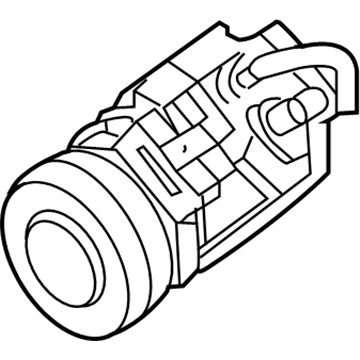

2006 Jeep Liberty Compressor Part Number: 55037467AE

$546.56 MSRP: $732.00You Save: $185.44 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor

- Replaces: 55037467AB, 55037467AC, 55037467AD, RX037467AD

- Item Weight: 5.10 Pounds

- Item Dimensions: 9.7 x 9.8 x 9.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 55037467AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

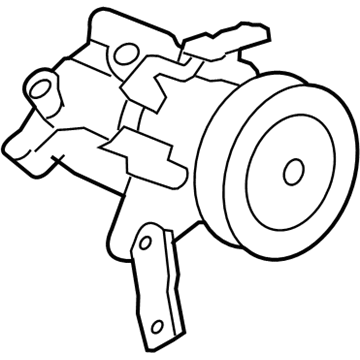

2006 Jeep Liberty Compressor Part Number: 55111406AD

$458.52 MSRP: $690.00You Save: $231.48 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor A/C

- Replaces: 55111400AE, 55111400AB, 55111406AB, 55111400AC, R5111406AF, R5111400AH, R5111406AD, R5111400AE, R5111406AG, 55111400AA, 55111406AC, 55111406AA, R5111406AE, RL111406AD, R5111400AG, 55111400AD, RL111400AE

- Item Weight: 16.10 Pounds

- Item Dimensions: 9.4 x 9.4 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 55111406AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Jeep Liberty A/C Compressor Parts and Q&A

- Q: How to Service the Clutch on a Visteon A/C Compressor on 2006 Jeep Liberty?A: Servicing the A/C compressor clutch on a Visteon A/C compressor requires you to remove the car's negative battery cable and the accessory drive belt first. Separate the engine wire harness from the clutch field coil connector and take out the bolts holding the A/C compressor to the bracket so that the compressor remains secure during the clutch service. Loosen the bolt that holds the clutch plate to the compressor with a strap wrench, except if you can gently remove it by hand or a small bolt. Be sure to remove every clutch plate shim. After that, eliminate the clutch plate and shim(s) from the A/C compressor and, if necessary, use a 8 x 1.25 mm bolt during the process. You can simply use snap ring pliers to remove the snap ring that secures the pulley and bearing assembly to the front of the A/C compressor. If you don't have them, you can use hand tools or a two jaw puller to remove the assembly too. Take out the screw holding the clutch field coil wire lead bracket to the A/C compressor and remove the clutch field coil using both a remover and a two jaw puller from the front of the compressor. When setting the clutch field coil, place it square to the front of the A/C compressor and verify the wiring and positioning tabs are right. Pop up the field coil positioning tabs, then set the clutch field coil in place with a two jaw puller, compressor field coil installer and compressor field coil installer spacer. Wrap the clutch field coil wire lead around the compressor's bracket, attach it by screwing it tightly and hold it with a torque of 4 N.m (35 in. lbs.). Square up the pulley and bearing assembly at the A/C compressor's front, then use a hammer and clutch pulley installer to install it until the assembly bottoms against the compressor housing. Put the snap ring in the groove, facing its bevel outward for a seat that is secure. Check if there is enough gap for the wire from the clutch field coil to pass between the A/C compressor and the pulley and bearing. Screw the clutch shims onto the compressor shaft and lock the compressor piston to the A/C collar using a strap wrench. The bolt should be tightened to 15 N.m (133 in. lbs.). Measure the air gap between the clutch plate and the pulley and bearing assembly using 90 degree wire gauges, then change the shims to make sure the gap is 0.35 to 0.65 millimeter (0.014 to 0.025 inch). Anchor the compressor on the bracket with the supplied bolts, connect the engine wire harness to the clutch field coil circuit of the compressor, place on the accessory drive belt and link it to the alternator. The last step is the Clutch Break-in Procedure.