JeepParts

My Garage

My Account

Cart

OEM 2007 Chrysler Sebring ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 ABS Control Modules found

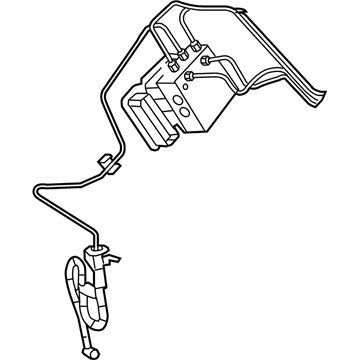

2007 Chrysler Sebring Modulator Valve Part Number: 5179854AA

$916.03 MSRP: $1305.00You Save: $388.97 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Master Cylinder - Anti-Lock Brake System; ABS Modulator Valve; ABS Control Module; Modulator; Hydraulic Control Unit Anti-Lock Brake System

- Item Weight: 6.60 Pounds

- Item Dimensions: 8.2 x 8.0 x 7.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5179854AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

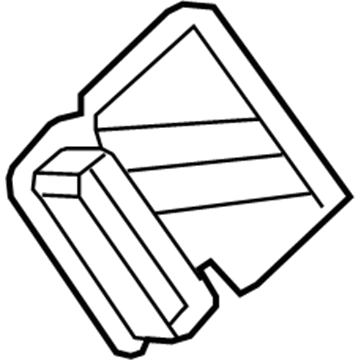

2007 Chrysler Sebring Control Module Part Number: 68021920AC

Product Specifications- Other Name: Module - Anti-Lock Brake System; ABS Control Module; Modulator Valve; ABS Control Unit

- Replaces: 68021920AB, 68021920AA

- Item Weight: 2.10 Pounds

- Item Dimensions: 7.3 x 7.1 x 7.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68021920AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

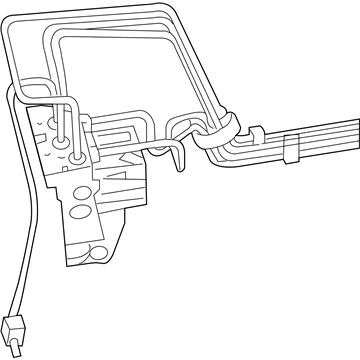

2007 Chrysler Sebring Modulator Valve Part Number: 5179862AA

Product Specifications- Other Name: Master Cylinder - Anti-Lock Brake System; ABS Control Module; ABS Control Unit; Hydraulic Control Unit Anti-Lock Brake System

- Item Weight: 5.00 Pounds

- Item Dimensions: 7.0 x 6.8 x 6.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5179862AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

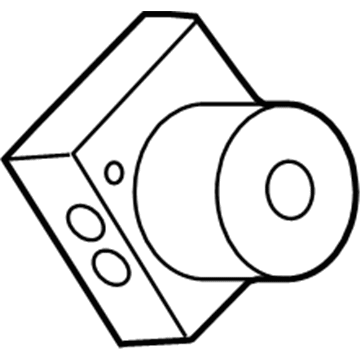

2007 Chrysler Sebring Control Module Part Number: 68021921AC

Product Specifications- Other Name: Module - Anti-Lock Brake System; ABS Control Module; ABS Control Unit

- Replaces: 68021921AB, 68021921AA

- Item Weight: 2.40 Pounds

- Item Dimensions: 6.3 x 6.4 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68021921AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2007 Chrysler Sebring ABS Control Module Parts and Q&A

- Q: How to Install the ABS Control Module for a 2.0L/2.4L Engine on 2007 Chrysler Sebring?A: For the 2.0L/2.4L engine, fit the ICU with its bracket between the A/C lines and the exhaust manifold and replace it using the reverse process followed during removal. Put the ICU mounting bracket over the screw holes and then tighten both screws to 23 Nm (17 ft. lbs.). Make sure the seal is securely inserted in the ABM harness connector before you put the ABM wiring harness connector into the socket and snap it in. The next step is to install the four chassis brake tubes at the ICU hydraulic system tightening the tube nuts to 17 Nm (150 in. lbs.), then install the primary and secondary brake tubes, following the same method. Fasten the brake tube bundle routing clips to the studs on the dash panel and after that, slide the dash panel heat shield in place, tightening the lower and upper nuts. After removing the brake pedal holding tool, assemble the engine's appearance cover and link the negative battery cable to the post. Next, attach the scan tool, so it can initialize the ABM, clear any fault codes, pump the master cylinder to the proper amount, bleed the base and ABS hydraulic systems, check for leaks around each wheel and run the ABS Verification Test followed by a road test.