JeepParts

My Garage

My Account

Cart

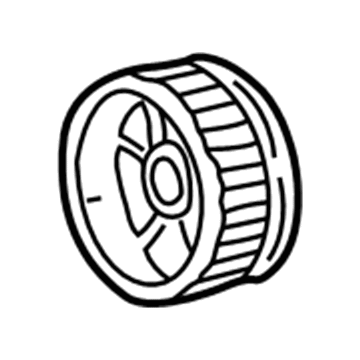

OEM Chrysler 300M Cam Gear

Camshaft Gear- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Cam Gears found

Chrysler 300M Camshaft Gear, Driver Side Part Number: 4792580AA

$48.66 MSRP: $61.68You Save: $13.02 (22%)Ships in 1-2 Business Days

Chrysler 300M Camshaft Gear, Driver Side Part Number: 4792224

$50.23 MSRP: $63.68You Save: $13.45 (22%)Ships in 1-2 Business DaysChrysler 300M Camshaft Gear, Passenger Side Part Number: 4792025

Chrysler 300M Cam Gear

Choose OEM Cam Gear that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Cam Gear follows strict manufacturing steps to lock in quality and fit. If your Chrysler 300M matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine 300M parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

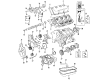

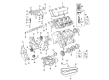

This is the Chrysler 300M Cam Gear a part that can has a large influence on the dependability as well as quality of the car. As a part of the valve operation mechanism, the Cam Gear has been manufactured with the special purpose of controlling the valve timing in an effective and efficient manner Hence, the Chrysler 300M boost torque and horsepower. There is an influencing adjuancy, whereby the values open and result to closure when it is most propitious for the intended production of power output. By addressing the high-detail precision of the Cam Gear on the Chrysler 300M equipped with a 3.5L V6 engine, it can be safely assumed that Chrysler has one of the strongest competitors in today's automotive market. As for the Cam Gear part, it works on different 300M models, as the main task always remains the same, making all the cars perform as they should. Thus, the Cam Gear is greater than just shaping the performance of a car - it adds to safety by guaranteeing that the engine of the car is well balanced and therefore prevents mechanical breakdowns. It also has a number of special characteristics such as build quality of the Chrysler 300M Cam Gear, and precise engineering one of the greatest strengths of this part. Playing a very crucial role of linking the camshaft, the Cam Gear is a driving factor and presence of the Chrysler 300M at the car mart is not a spectacle but a statement that promises performance and reliability to the automobile community. First of all, the component is an amazingly effective and designed piece for technology enthusiasts and regular drivers of the Chrysler 300M.

Chrysler 300M Cam Gear Parts and Q&A

- Q: How to Remove and Replace the Cam Gear on 3.2/3.5L Engines on Chrysler 300M?A:Drain the radiator, remove the Drive Belts and take off the crankshaft damper and Timing Belt covers as well as the timing belt for removing and changing the camshaft gear/sprocket on these engines. Do not attempt to rotate the camshafts or crankshafts when the timing belt is removed, as the engine won't start freely. After undoing or removing the camshaft sprocket bolts, the camshafts have to be re-timed and you should not reuse the bolts. Place a 36 mm (1 7/16 inch) box wrench on the camshaft sprocket to secure it, then use a socket to unscrew and remove the bolt and washer; lifting that section of the engine may sometimes help because the bolts are so long (213 mm (8 3/8 inch) for the right and 255 mm (10.0 inch) for the left). Remove the camshaft sprocket, making sure it aligns properly with the engine, being sure it is timed correctly. To time the engine, connect the oil pump sprocket at the top dead center on the housing and then use a dial indicator in cylinder number 1 to see if it is at TDC. Using a crankshaft, align the piston on TDC and next, put in Special Tools 6642 into the rear of every cylinder head. With a gentle pull, adjust the tensioner in a vice and add the locking pin before setting aside the tensioner so the plunger is facing up. Attach both sprockets to the camshafts using new bolts: 255 mm (10 inch) for the left and 213 mm (8 3/8 inch) for the right, so the sprocket marks sit between the cover marks. Adjust the timing belt clockwise in order to fit it around the tensioner pulley, making sure there is tension as you put it on. Slide the tensioner into the housing and tighten to 28 Nm or 250 in. lbs., then pull the retaining pin so the tensioner extends out. Place the camshaft sprocket hex inside the number 1 piston and tighten the camshaft bolts to 75 ft. lb. for the right and 85 ft. lb. for the left, each with a 90° turn after you reach 102 Nm and 115 Nm respectively. First, take off the dial indicator, place the new spark plug and lastly, remove the alignment Special Tools 6642. Cover your cams and O-rings, secure all the fastening bolts at 28 Nm (250 in-lbs), then install the remaining covers, the crankshaft damper and the other drive belts. After filling the cooling system, begin the engine and let it run without moving for about 1 minute. If you can hear a strong noise coming from the timing belt or tensioner, air may be inside the tensioner; run the engine at 1600-2000 RPM for 10 minutes with a DRB III to remove the air. In case air is present, the tensioner will feel spongy and whistle, but these symptoms should go away after your engine has run for 15 minutes or less.

- Q: How to Maintain and Fix a Cam Gear on Chrysler 300M?A:The first step in working with the camshaft gear/sprocket is to take apart the front Timing Belt covers. Do this step by rotating the crankshaft CCW until the crankshaft sprocket falls at the TDC mark on the oil pump housing. Set a dial indicator in the number 1 cylinder at TDC to check the Piston, then take out the camshaft retainer/thrust plates from the back of the cylinder heads and get to the right side plate by removing the EGR Valve. Insert the pin from Special Tool 6642 into the pilot hole on the camshaft and attach the bolts to the retainer plate; if alignment is bad, remove the Timing Belt Tensioner, rotate the camshaft until the bolts can be fitted and do not install the tensioner. Following this, take out the timing belt and hold the camshaft sprocket using a 36 mm box end wrench when loosening and removing both bolts and washers. Detach the camshaft sprockets and be sure they are not reversible from one side to the other. During installation, slide the new sprockets onto the camshafts and insert the new bolts without tightening, so that the sprocket marks are set between the marks you see on the cover. Always install the timing belt around the front of the crankshaft sprocket and move it counterclockwise with pressure on the tensioner pulley. Secure the tensioner pulley against the belt and attach the reset timing belt tensioner, screwing the bolts until the tension is 28 Nm. Drop the tensioner retaining pin, use a dial indicator to put number 1 piston at TDC and finish by tightening the right camshaft bolts to 102 Nm after a 90° turn and the left ones to 115 Nm after the same turn. When you finish with the dial indicator, install the spark plug, then remove Special Tool 6642 and attach the cam retainer/thrust plates and O-rings, fastening all the bolts to 28 Nm. Once all that is done, fit the timing belt covers, crankshaft vibration damper and accessory Drive Belts and finish by filling the cooling system.