JeepParts

My Garage

My Account

Cart

OEM Dodge Caliber Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Pistons found

Dodge Caliber Piston Part Number: 5191341AA

$162.84 MSRP: $247.00You Save: $84.16 (35%)Ships in 1-2 Business DaysDodge Caliber Piston Part Number: 5191335AA

$74.01 MSRP: $107.00You Save: $32.99 (31%)Ships in 1-2 Business DaysDodge Caliber Piston Part Number: 5191342AA

$128.02 MSRP: $193.00You Save: $64.98 (34%)Ships in 1-2 Business DaysDodge Caliber Piston Part Number: 5191336AA

$67.91 MSRP: $108.00You Save: $40.09 (38%)Ships in 1-2 Business DaysDodge Caliber Oil Pump Part Number: 5191337AA

$102.41 MSRP: $212.00You Save: $109.59 (52%)Ships in 1-2 Business DaysDodge Caliber Piston Part Number: 5191338AA

$130.19 MSRP: $184.00You Save: $53.81 (30%)Ships in 1-2 Business DaysDodge Caliber Piston Part Number: 5191339AA

$102.24 MSRP: $136.00You Save: $33.76 (25%)Ships in 1-2 Business DaysDodge Caliber Piston Part Number: 5191334AA

Dodge Caliber Piston Part Number: 4884843AH

Dodge Caliber Piston Part Number: 4884842AH

Dodge Caliber Piston Part Number: 4884841AH

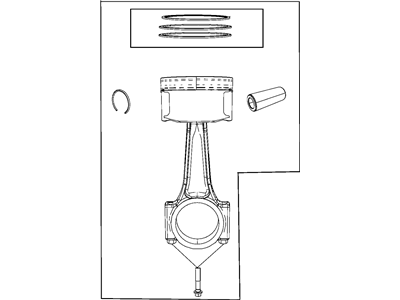

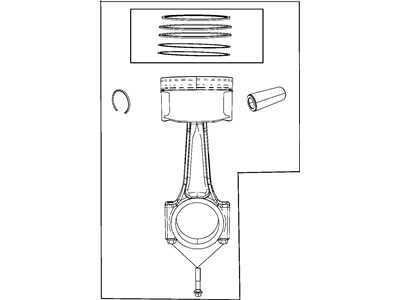

Dodge Caliber Piston

Choose OEM Piston that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Piston follows strict manufacturing steps to lock in quality and fit. If your Dodge Caliber matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Caliber parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

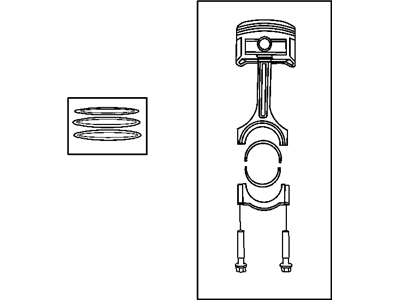

The Dodge Caliber Piston play a very vital role in boosting up the performance and durability of Dodge Caliber automobiles. With the help of specialized aluminum alloys, these pistons combine low weight with high strength increasing the efficiency of power combustion into motion. The Dodge Caliber with body style C and Compact car manufactured from 2007 to 2012 has good safety features and is economical when it comes to the usage of fuel thus the quality of pistons is very vital. For the petrol and diesel engines, trunk pistons are used in different Dodge Caliber models thus to conform with them and improve the general performance of the vehicle. The Dodge Caliber Piston is vital in enhancing the calibers of the engine but also has a significant role in safety since a good piston can eliminate engine problems that may force the car off the road in a bid to meet safety standards. Some of the features of the Dodge Caliber Piston include; the special designs for racing at the high revolution per minute among others that point to its versatility and performance. These pistons also play a role in achieving the admirable reliability of the Dodge Caliber; manufactured for the demanding and arduous requirements of everyday use and racing. It becomes clear why the product has great testimonials and it becomes obvious why it can be an important key for any patriot caliber proprietor that requires to boost the performance of their vehicle.

Dodge Caliber Piston Parts and Q&A

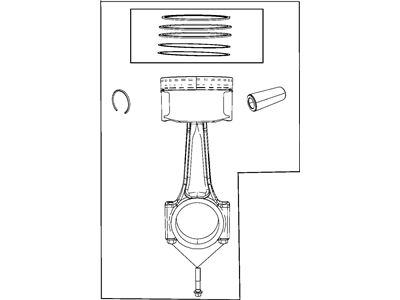

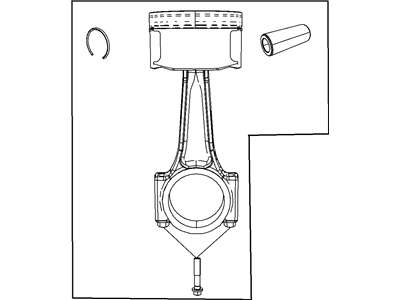

- Q: How to Remove and Replace a Piston and Connecting Rod Assembly on Dodge Caliber?A:You should remove the engine from the vehicle to reach the piston and connecting rod assembly. Set the engine on an engine stand after it has been removed from dolly 6135. After that, take off the cylinder head, empty the engine oil and take the Oil Pan and Oil Filter away. Get rid of the balance shaft assembly and the ladder frame. Before you pull the piston, remove any dirt or carbon from the cylinder to make sure you don't damage the piston skirts when removing it. Cover the tops of the pistons and remove the top ridges in the cylinder bores using a good ridge reamer. Adjust the Crankshaft so that each connecting rod is centered in its cylinder and draw the cylinder number on each cap with a permanent ink or paint marker, instead of using a number stamp or punch. Take out the bolts connecting the rod to the crankshaft and the cap, without reusing them. Gently slide each piston and connecting rod set out of the cylinder bore, insert the bearing cap onto the mating rod and do this process for all of the assemblies.

- Q: How to Install Piston and Connecting Rod Assemblies on Dodge Caliber?A:First, fit on the piston rings so that you don't have both the upper and lower compression ring gaps touching the oil ring rail of the cylinder. Check that the oil ring expander ends are butted together and the rail distance is proper when seen from the top of the piston, before using the ring compressor. Put the piston head and rings in engine oil first and then, using the ring compressor, slide it onto the piston without moving the ring positions. It is necessary that the directional arrow on the piston is pointing toward the front of the engine. Turn the crankshaft so that the connecting rod is in the middle of the bore and put a bit of clean oil on the connecting rod journal. Look for the right Rod Bearing, according to the crankshaft nose label and install that into the connecting rod with the connecting rod upper bearing half. With the use of the ring compressor, gently press the piston into the cylinder while guiding the connecting rod into position and using a hammer handle. Putting new, oil-treated bolts through the cap and secured can replace the old bolts. Make each bolt finger tight, then go back and forth torquing them to 20 Nm (15 ft. lbs.) and turning them on top of that another 90 degrees without a torque wrench for the second stage. Insert a feeler gauge on the connecting rod end to make sure it does not touch. Now, put in the ladder frame, oil pump, Oil Pan and cylinder head. After that, put the engine lift chain in place and secure the engine.