JeepParts

My Garage

My Account

Cart

OEM Dodge Dakota Battery Cable

Car Battery Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

36 Battery Cables found

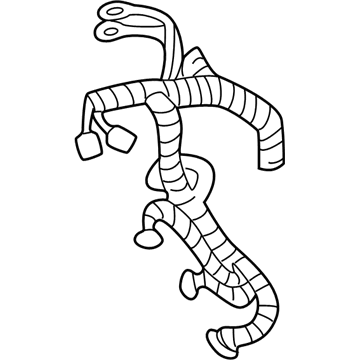

Dodge Dakota Wiring Harness Part Number: 4801621AC

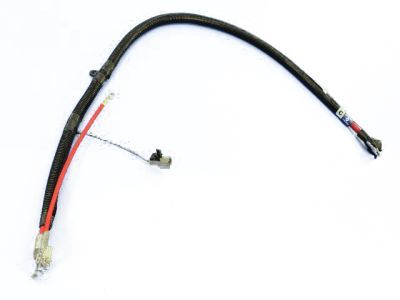

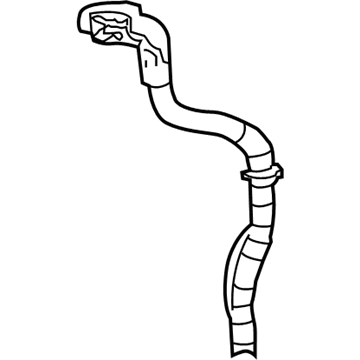

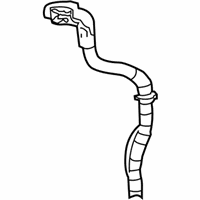

Dodge Dakota Positive Cable Part Number: 56051122AC

Dodge Dakota Cable Assembly Part Number: 56007291

Dodge Dakota Negative Cable Part Number: 56018810AC

Dodge Dakota Wiring Harness Part Number: 4801661AC

Dodge Dakota Positive Cable Part Number: 56049535AA

Dodge Dakota Wiring Harness Part Number: 4801662AD

Dodge Dakota Positive Cable Part Number: 56049640AE

Dodge Dakota Positive Cable Part Number: 56049538AA

Dodge Dakota Positive Cable Part Number: 56049649AE

Dodge Dakota Positive Cable Part Number: 56051121AC

Dodge Dakota Wiring Harness Part Number: 4801660AD

Dodge Dakota Wiring Harness Part Number: 4801622AC

Dodge Dakota Positive Cable Part Number: 56049537AA

Dodge Dakota Positive Cable Part Number: 56049534AA

Dodge Dakota Positive Cable Part Number: 56049536AA

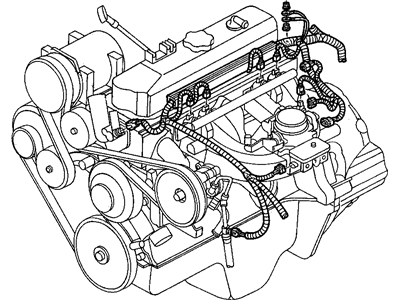

Dodge Dakota Engine Harness Part Number: 56049137AD

Dodge Dakota Engine Harness Part Number: 56049136AD

Dodge Dakota Engine Harness Part Number: 56049139AE

Dodge Dakota Positive Cable Part Number: 4801273AC

| Page 1 of 2 |Next >

1-20 of 36 Results

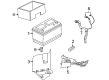

Dodge Dakota Battery Cable

Choose OEM Battery Cable that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Battery Cable follows strict manufacturing steps to lock in quality and fit. If your Dodge Dakota matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Dakota parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Dakota Battery Cable are mainly used as connectors of electrical current that enables the provision of power from the battery to the car's starter and engine. These cables, however, may deteriorate with time and get oxidized or damaged; this afterwards results in poor connection and starting issues. One should ensure that it is a regular practice to inspect the battery cables with an aim of avoiding breakdowns on the road. This way, you can keep an up to date and free of defects cables and in this way to have a great connection of the battery with the electrical components and guarantee that each time starts without problems the engine.

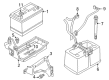

Dodge Dakota Battery Cable Parts and Q&A

- Q: How to Properly Install Battery Cables on Dodge Dakota?A:Start by inserting the battery negative cable in the appropriate part of the engine harness conduit, position it in the car and use the supplied pushpins, fasteners and clips to make the cable secure. After that, put in the negative cable eyelet bolt to the left front fender and tighten it to 20 Nm. Lift the vehicle onto a hoist and fit the bolt connecting the negative cable to the engine block, turning it until it reaches 16.5 Nm of torque. Attach the battery negative cable terminal clamp to the vehicle and screw the pinch-bolt hex nut with your 5 Nm wrench. Note whether the vehicle is running in its usual manner. After placing the battery positive cable in the vehicle, mount the nut holding the cable to the Integrated Power Module stud and tighten it to 11.5 Nm. Put the nut that holds the cable onto the Alternator, tighten it to 14 Nm and then insert the cable pushpin into the left frame rail. Join the starter solenoid wire harness connector, lift the vehicle on a hoist and fit the indicated nut to secure the cable to the starter solenoid, made firm at a torque rating of 13 Nm. Clone the battery cable pushpin into the block, lower the car and tighten the battery positive cable clamp, using a 5 Nm pinch-bolt hex nut. Set the air intake resonator into the vehicle, bolt it in and wrap the band around the air inlet tube. After that, attach the battery negative cable terminal clamp and tighten its pinch-bolt hex nut to 5 Nm, before running a test on the vehicle.

- Q: How to Maintain and Fix Battery Cables on Dodge Dakota?A:To work on the battery cables, switch off the ignition and check that electrical equipment is turned off. Disconnect and isolate the left side, negative cable terminal clamp (4) and then remove the bolt (2) from the negative cable mounting eyelet (3). Take out all the pushpins, fasteners and routing clips that keep the battery cable in the vehicle, then remove the cable. Secure the vehicle on a hoist, unfasten the bolt (3) connecting the negative cable (1) to the engine (2), pull the cable out of the nearby conduit and finally remove the cable from the battery. Again, set the ignition to Off, shut down all electrical accessories and remove and isolate the battery negative cable. Release the clamp (2) holding the tube (1) and remove all the bolts (3) from the resonator (4) before taking it out of your vehicle. Unplug the positive battery cable from the terminal on (8), then remove the nut (5) holding it to the stud (6) on the Integrated Power Module (IPM) (7). Remove the nut from under the cap of terminal (3), take out the wire from the black connector (1) and remove the pushpin attached to the cable at the left frame rail (4). Jack up your vehicle on a hoist, take off the nut (2) joining the cable (1) to the starter solenoid (3) and unplug the battery cable pushpin (6) from the engine block. Lift the vehicle and take out the positive cable from the battery at the end.