JeepParts

My Garage

My Account

Cart

OEM Dodge Grand Caravan Automatic Transmission Filter

AT Filter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Automatic Transmission Filters found

Dodge Grand Caravan Auto Transmission Filter Part Number: 4864505AB

$44.78 MSRP: $66.80You Save: $22.02 (33%)Ships in 1-2 Business Days

Dodge Grand Caravan Filter Assembly Part Number: 68018555AA

$45.24 MSRP: $65.10You Save: $19.86 (31%)Ships in 1-2 Business DaysDodge Grand Caravan Auto Transmission Filter Part Number: 4269649

$6.69 MSRP: $9.45You Save: $2.76 (30%)Ships in 1-2 Business Days

Dodge Grand Caravan Automatic Transmission Filter

Choose OEM Automatic Transmission Filter that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Automatic Transmission Filter follows strict manufacturing steps to lock in quality and fit. If your Dodge Grand Caravan matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Grand Caravan parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Automatic Transmission Filter in Dodge Grand Caravan automobiles is extremely important in the overall functioning of this part. Its main purpose is to hold contaminants in the tranny fluid to ensure that they do not block the passages and cause operational problems of moving parts. These filtrations are very much useful for avoiding the transmission problems and for avoiding the high costs. Many Dodge Grand Caravan models have used different types of Automatic Transmission Filters with time, these include the transmission fluid pan-embedded filters, and the spin on or the cartridge type. The internal filters can either be replaced by removing a few modules in regular preventive and maintenance checks or they might be of very complex structures, where the replacement may make the owner destroy the majority part of the device to be able to substitute filters. On the other hand external filters allow easy access and frequent changes to be made as necessary. There are performance Automatic Transmission Filters which in most cases has better filtration capability and higher flow rates compared to normal filters, this helps in the achievement of better fuel economy and longer transmission life of the Dodge Grand Caravan.

Dodge Grand Caravan Automatic Transmission Filter Parts and Q&A

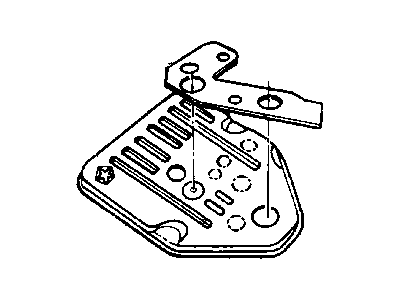

- Q: How to Change the Automatic Transmission Filter and Fluid on Dodge Grand Caravan?A:Before doing anything else, find out from the manufacturer when the fluid and filter should be serviced. Only use leopard ATF +4 and exchange the filter throughout your transmission oil changes. After removing the magnet inside the Oil Pan, wipe it clean with a dry, lint-free cloth and change both the fluid and filter if you took the transaxle apart. First, put as much weight on the vehicle as possible by lifting it with a hoist and place a drain container under the transaxle oil pan. Before pulling the oil pan, detach the two nuts from the engine crossmember cradles, use a screw jack and a block to lift the engine and transmission and hold them in position with a mechanic's stand. Slot the bolts, give one corner a quick tap and pull the oil pan away to let the oil empty. Insert a new filter and o-ring at the bottom of the Valve Body, wash and clean the oil pan and magnet and then put the oil pan back in place, using new Mopar Silicone Adhesive and tightening the bolts to 19 Nm (165 inch lbs.). Pour through the dipstick opening, start your car and let it idle for one minute. With your car stopped and the brakes engaged, temporarily put the gear selection lever in all positions, until you finish at park or neutral. Following the guide, add more fluid to get the fluid level at 3 mm (1/8 inch) below the bottom mark and check it again when the transaxle reaches normal operating temperature (180°F). Seat the dipstick properly so that any dirt won't get inside the transaxle. To use the dipstick tube fluid suction method, let the transaxle operate until it reaches its normal temperature, pick a suitable device and put the suction line in the dipstick tube to reach the bottom of the oil pan. After the fluid has been taken out, take away the suction line and fill the ATF +4 up to the filled mark on the dipstick. Turn on the engine and check the liquid level as you did earlier, sitting the dipstick down properly.

- Q: How to Properly Service and Replace an Automatic Transmission Filter in a 62TE Transaxle on Dodge Grand Caravan?A:Only use Mopar® Atf+4 fluids during the fluid and filter service of the 62Te transaxle and don't forget to change the filter as you change the transmission oil. If the transaxle is taken apart, changing the fluid and filter is also required. Lift the car up on a hoist and locate a drain container under the Oil Pan on the transaxle side. Tighten the pan bolts first, then tap a corner to let the fluid out and then remove the oil pan carefully. Then, take off the nuts under the Oil Filter, add a new filter and put its nuts on, but make sure the nuts aren't over-tightened (5 Nm or 40 in. lbs.). Apply a bead of Mopar® Atf Rtv (Ms-Gf41) to the fluid filter oil pan, clean and attach the magnetic drain pan and seal the new pan to the oil pump using Mopar® Silicone Adhesive, tightening all pan bolts to 6 Nm (50 in. lbs.). Add four quarts of Mopar® Atf+4 to the dipstick through the fill hole, then start up the engine and run it for at least one minute without turning. When the parking and service brakes are applied, slightly move the selector lever through each range, ending it in park or neutral. Look at how much liquid is in the transaxle and pour enough to raise the level 3 mm (1/8 in.) below where the lowest mark is on the stick. As soon as the transaxle is at its normal operating temperature of 82°C, kick-down operation becomes available. Check the fluid level after the car finishes its first cool-down with the engine at C (180°F). By having the dipstick locked down in its opening, you can prevent dirt from reaching the transaxle.