JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Van A/C Hose

Air Conditioning Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 A/C Hoses found

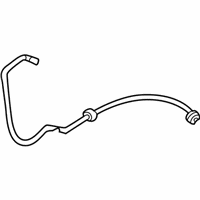

Dodge Ram 3500 Van Discharge Line, Front Part Number: 55037328AB

Dodge Ram 3500 Van Suction Line, Front Part Number: 5003269AD

Dodge Ram 3500 Van Suction Line Part Number: 5003268AE

Dodge Ram 3500 Van Suction Line Part Number: 5003267AE

Dodge Ram 3500 Van Suction Line, Rear Part Number: 5003262AC

Dodge Ram 3500 Van Suction Line Part Number: 5003114AB

Dodge Ram 3500 Van Liquid Line Part Number: 5003113AB

Dodge Ram 3500 Van A/C Hose

Choose OEM A/C Hose that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each A/C Hose follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 3500 Van A/C Hose Parts and Q&A

- Q: How to replace the A/C Hose (discharge line) on Dodge Ram 3500 Van?A:You should first isolate the negative battery cable and remove the A/C discharge hose/line after that. Take the wire connector off the high pressure cut-off switch and unfasten the radiator grille from your vehicle. Then, take out the screw holding the block fitting to the discharge line on the condenser and remove the fitting. After that, plug or tape up all open refrigerant line fittings. Unattach the flare nut at the suction line and put in a plug or tape over every opened fitting in that section. Screws near the compressor attach the refrigerant line, so release them and block the openings that appear with plugs or tape. Then, take out the suction and discharge line assembly from the vehicle. Take off the tape or plugs from the refrigerant line openings on the compressor and manifold, fit the manifold onto the compressor and tighten the mounting screw to 22 Nm (200 in. lbs.). Pull out the tape or plugs from the suction line fittings, line up the flare nut on the suction line with the suction line jumper and tighten to 47 Nm (420 in. lbs.). Tape or plug the discharge line block fitting and the condenser inlet, screw the liquid line onto the condenser inlet and tighten the screw to 22 Nm (200 in. lbs.). Attach the radiator grille again, fit the wire harness wire into the high pressure cut-off switch, link up the negative battery cable, empty the refrigerant system and fill it with fresh refrigerant.

- Q: How do kinks or sharp bends in an A/C Hose affect system capacity, and what precautions should be taken to ensure proper refrigerant system connections on Dodge Ram 3500 Van?A:Sharp bends in the refrigerant pipes can seriously limit the amount of refrigerant the system can handle and running it can cause high pressures, so connections must be checked carefully to stay leak-free. Always keep the flexible lines about ten times their diameter away from the corners and route them at least 80 mm (3 inches) from the exhaust manifold. Wrapping the flexible refrigerant system hose lines around the equipment at least once a year is suggested for maintenance and safety. Refrigerant fittings have two options: those with O-rings (that should be lubricated with refrigerant oil and fitted using only allowed O-rings for R-134a, to stop leaks) and unified plumbing connections with gaskets that must not be worked with O-rings, as their gaskets can't be reused and they don't need to be lubricated. Proper equipment is needed and using just two wrenches helps when handling tube fittings; use one wrench to hold the tube in place as you adjust the other end. All refrigerant should be removed from the system before opening any fitting or connection, as any visible pressure means the fittings need to be tightened and the refrigerant recovered. Offloading refrigerant directly into the environment is not allowed; rather, an R-134a recovery/recycling device complying with SAE Standard J2210 should be applied. As long as it is pure, moisture-free R-134a refrigerant in combination with refrigerant oil, the refrigerant system is stable and free from damage, but external dirt, moisture or air can affect the stability of the system. All necessary supplies and equipment should be ready before starting and refrigerant fittings must be plugged or capped immediately after the system is opened. To maintain safe use, it is important that all tools such as the ones mentioned, are kept clean, dry and fitted only for R-134a refrigerant.