JeepParts

My Garage

My Account

Cart

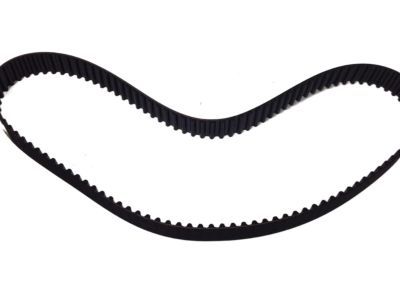

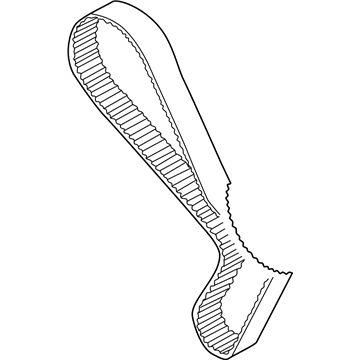

OEM Dodge Stratus Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Timing Belts found

Dodge Stratus Timing Belt Part Number: 4621844

$67.90 MSRP: $102.00You Save: $34.10 (34%)Ships in 1-2 Business DaysDodge Stratus Timing Belt Part Number: MD336149

$70.09 MSRP: $88.85You Save: $18.76 (22%)Ships in 1-2 Business Days

Dodge Stratus Timing Belt Part Number: 4667606

Dodge Stratus Timing Belt Part Number: MR984778

Dodge Stratus Timing Belt Part Number: 5183004AA

Dodge Stratus Timing Belt

Choose OEM Timing Belt that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Timing Belt follows strict manufacturing steps to lock in quality and fit. If your Dodge Stratus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Stratus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Dodge Stratus Timing Belt is an essential feature that explains the dependability and power of Dodge Stratus cars and trucks; it connects the crankshaft and camshaft to maintain harmony. This precision is important so that engine can function at optimal, opening and closing of the valves at the right time. The Dodge Stratus that was manufactured between 1995 and 2005 is also benefited from the advancement of timing belts over timing chains and gears due to their factors of; Quiet operation, fairly cheaper, and more dependable. Latest designs that have been developed incorporate curved teeth, thus the Dodge Stratus Timing Belt can serve up to 60, 000 miles or more while enhancing on the efficiency and safety of an engine. Maintenance of the timing belt requires that it should be replaced often as recommended by the manufacturer, this is more so for interference engines, a broken belt with cause extensive damage to the engine. The Dodge Stratus Timing Belt can fit with most of the models of the car right from the sedan to the coupe consequently, it is suitable for all the car lovers. Also, proper tensioners and idler pulleys are incorporated during replacement for enhance the performance of the systems. The Dodge Stratus appeals to auto users in the market niceties of refinement, performance, and affordable price tag, and that make the timing belt an essential component of the car's reputation in the market. In summary, the Dodge Stratus Timing Belt improves the car's power output and reliability and establishes it as the perfect car for money-minded drivers who will not compromise on power and performance.

Dodge Stratus Timing Belt Parts and Q&A

- Q: How to Properly Remove and Install a Timing Belt on a 2.0L SOHC Engine on Dodge Stratus?A:When the timing belt is removed, make sure not to turn the Camshaft on the 2.0L SOHC engine, since it can lead to valve damage. When the cover is on, remove the number one spark plug and adjust the number one cylinder's position to TDC on the compression stroke with a dial indicator. Remove the outer timing belt cover's access plug and confirm that the mark on the camshaft sprocket points to the same arrow that's on the rear belt cover. For the timing belt to be removed, you must disconnect the negative battery cable, take off the accessory Drive Belts, lift the vehicle with a hoist and remove the right inner splash shield along with the right front wheel. Use the large side of 1026 and Special Tool 1026-A to take out the crankshaft damper and bolt and then lower the vehicle and install a jack under the engine. Then, remove the right Engine Mount, generator and bracket and the right engine mount bracket. Take out the drive belt idler pulley from the generator bracket, separate the generator bracket from the engine and remove the front timing belt cover. You should move the engine crankshaft until the mark on it and camshaft are properly matched before taking out the timing belt. First, place the crankshaft sprocket at TDC by locating the arrow on the oil pump housing and then back it off by 3 notches prior to TDC. For belt installation, set the camshaft to TDC by placing the mark on the sprocket with the arrow on the rear of the timing belt cover and turn the crankshaft to the 1/2 position just before TDC. Put the timing belt on the crankshaft first, then around the water pump sprocket and finally around the camshaft sprocket. Move the crankshaft sprocket to the top dead center, then take out the 1/8" or 3 mm Allen wrench from the belt tensioner, rotate the crankshaft 2 turns and check where the timing marks are aligned. Attach the front side of the Timing Cover, the generator bracket and attaching bolts, then fit the idler pulley to the generator bracket, put on the engine mount bracket and connect the generator bracket to the engine. Tighten all the bolts to 61 Nm (45 ft. lbs.). Set up the generator, secure the right engine mount and take out the jack from underneath the engine. Install the crankshaft damper with the M12-1.75 x 150 mm bolt found in Special Tool 6792, along with a washer, thrust bearing and nut and tighten the crankshaft damper bolt to 142 Nm (106 ft. lbs.). After that, put on the accessory drive belts, use a hoist to install the right inner splash shield, mount the right front wheel, lower the car and connect the negative battery cable.

- Q: How to Maintain and Fix a Timing Belt on Dodge Stratus?A:Before working on the timing belt and sprockets, turn off the battery, lift the car on a hoist, remove the right front wheel and pull off the belt splash shield. Then, remove the accessory Drive Belts, take out the Crankshaft damper and the AC/Generator belt tensioner and lastly, cut all the generator wires to take the generator and its bracket out. Open the upper timing belt cover, the lower timing belt cover, the coolant recovery container, remove the right Engine Mount and the engine support bracket. Turn the crankshaft so that the TDC mark on the oil pump lining up with the TDC mark on the crankshaft sprocket, with the trailing side of the sprocket tooth also lined up. Turn the top plate of the Timing Belt Tensioner pulley clockwise using a 6 mm Allen wrench and after removing the tensioner lock bolt, you can slip the timing belt off. If issues with tracking caused trouble with the timing belt, change the assemblage of tensioner pulley and bracket instead of simply replacing the stress belt. To take off a camshaft sprocket, set Special Tool 6847 in place then remove the center bolts and for the crankshaft sprocket, insert Special Tool 6793 and use C-4685-C2 to release them. Never clean a timing belt; if it gets dirty, change it and clean all the sprockets with the right solvent. After installing the crankshaft sprocket with the right depth thanks to Special Tool 6792, add the timing belt and reattach the negative Battery Cable. Camshaft sprockets should be installed with Special Tool 6847 while holding them and then the center bolt must be tightened to 115 Nm (85 ft. lbs.). Adjust the crankshaft sprocket to TDC with the arrow on the oil pump housing and then place the exhaust camshaft sprocket below the intake camshaft sprocket by about a half cut, so the arrows on the sprockets are pointing upward. Replace the timing belt by assembling it on the crankshaft, around the water pump sprocket, along the idler pulley, onto the camshaft sprockets and finally on to the tensioner. Spin the exhaust camshaft sprocket counterclockwise, using the marks to line them up and reduce the belt slack, then rotate the top plate of the belt tensioner pulley counterclockwise until the setting notch aligns with the spring tang. At that point, tighten the tensioner lock bolt to 25 Nm (220 inch lbs.). Turn the crankshaft two complete turns clockwise to get the belt in place and check that the timing marks are where they should be. If the spring tang is not within the approved limits, you should retension the spring. After that, fit the new engine mount support bracket, upper and lower timing belt covers (ensure the fasteners are torqued to 6 Nm (50 inch lbs.)), generator and bracket with connections, AC/Generator belt tensioner, crankshaft damper, right engine mount, coolant recovery container, accessory drive belts, belt splash shield, right front wheel and tie back in the negative battery cable.