JeepParts

My Garage

My Account

Cart

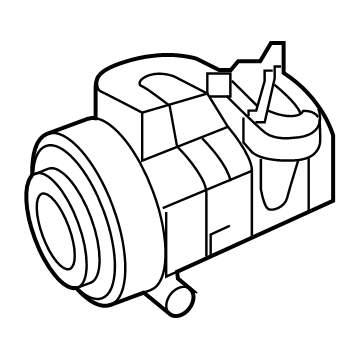

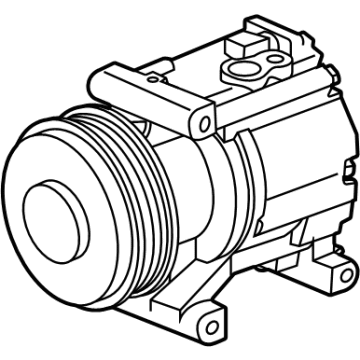

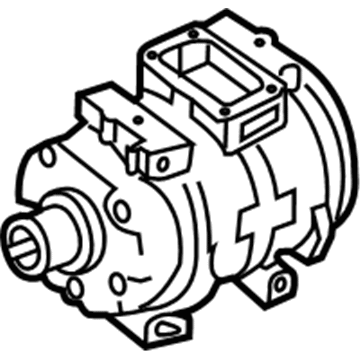

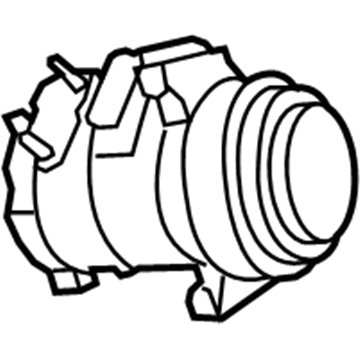

OEM Jeep A/C Compressor

Air Conditioning Compressor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

62 A/C Compressors found

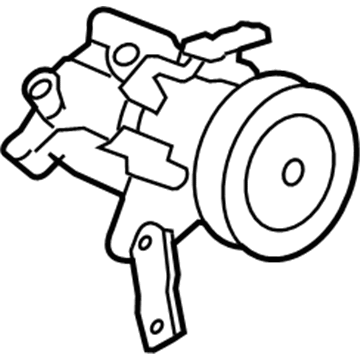

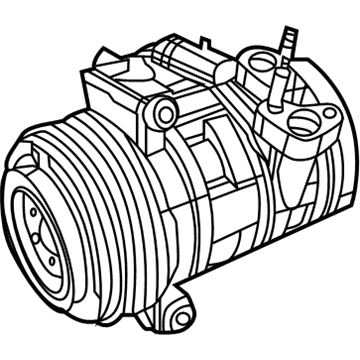

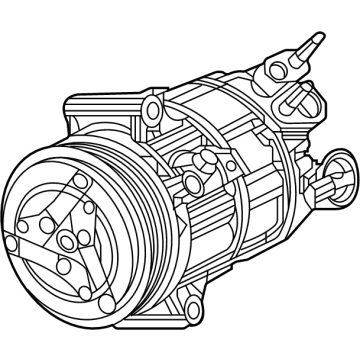

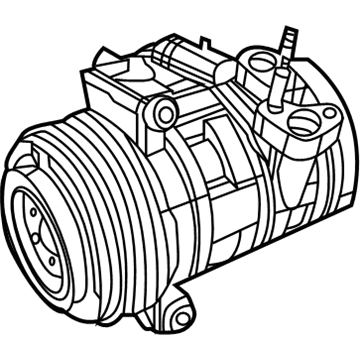

Jeep Compressor Part Number: 55111506AC

$552.94 MSRP: $811.00You Save: $258.06 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor

- Replaces: 55111506AA, R5111506AD, RL111506AB, R5111506AC, R5111506AB, 55111506AB

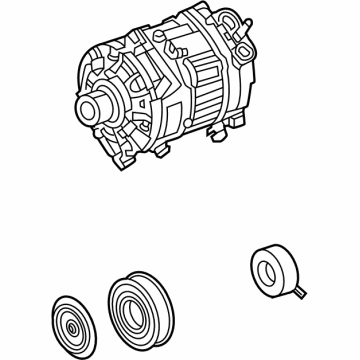

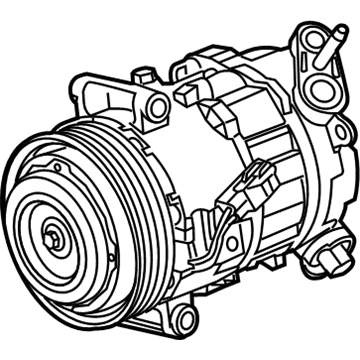

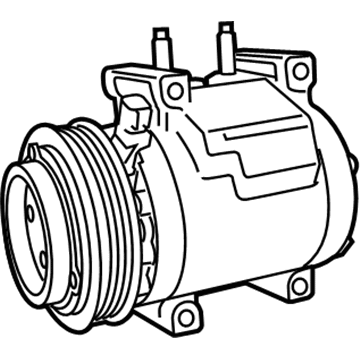

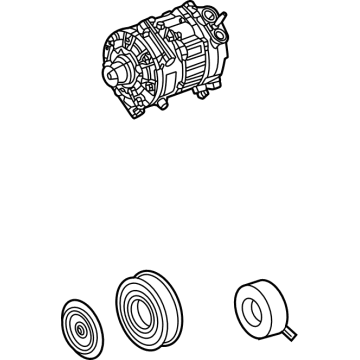

Jeep Compressor Part Number: 68459835AB

$222.07 MSRP: $328.00You Save: $105.93 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor

- Replaces: 68459835AA

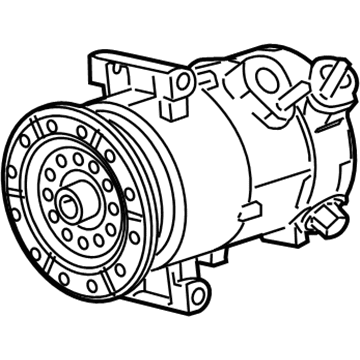

Jeep Compressor Part Number: 68292170AB

$493.88 MSRP: $744.00You Save: $250.12 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor A/C Complete

Jeep Compressor Part Number: 68292169AB

$491.67 MSRP: $740.00You Save: $248.33 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor A/C Complete

Jeep Compressor - A/C Part Number: 68202994AC

$430.90 MSRP: $652.00You Save: $221.10 (34%)Product Specifications- Other Name: COMPRESOR-AIR CONDITIONING

- Replaces: 68028917AC, 68028917AE, 68202994AB, RL028917AC, R8028917AB, 68028917AB, 68028917AD, 68202994AA, RL028917AB

Jeep Compressor - A/C Part Number: 57009909AA

$713.19 MSRP: $954.00You Save: $240.81 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: COMPRESSO-AIR CONDITIONING

Jeep Compressor Part Number: 68103197AE

$1008.81 MSRP: $1540.00You Save: $531.19 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C

- Replaced by: 68103197AG

- Replaces: 68103197AA, 68103197AD, 68103197AC, 68103197AB

Jeep Compressor Part Number: 68376684AE

$408.67 MSRP: $595.00You Save: $186.33 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor

- Replaces: 68376684AD

Jeep Compressor Part Number: 68439272AA

$815.44 MSRP: $1230.00You Save: $414.56 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor A/C

Jeep Compressor - A/C Part Number: 68415449AE

$191.39 MSRP: $280.00You Save: $88.61 (32%)Product Specifications- Other Name: AIR CONDITIONING

- Replaced by: 68415449AF

- Replaces: 68415449AD, 68415449AB, 68415449AC

Jeep Compressor Assembly Part Number: 55111096AC

$477.31 MSRP: $723.00You Save: $245.69 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor

- Replaces: 55111096AB, R5111096AC, RL111096AC

Jeep Compressor Part Number: 55116835AF

$668.47 MSRP: $1015.00You Save: $346.53 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor

- Replaces: 55116835AE

Jeep Compressor Part Number: 68481137AC

$390.01 MSRP: $590.00You Save: $199.99 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C

- Replaces: 68481137AB, 68481137AA

Jeep Compressor - A/C Part Number: 68202995AD

$1111.32 MSRP: $1500.00You Save: $388.68 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: COMPRESOR-AIR CONDITIONING

- Replaces: 68021835AF, RL021835AD, 68202995AC, 68021835AC, 68021835AE, 68202995AB, 68021835AD, 68202995AA, 68021835AB

Jeep Compressor Part Number: 68289890AB

$813.23 MSRP: $1225.00You Save: $411.77 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor A/C Complete

Jeep Compressor Part Number: 5058228AI

$522.61 MSRP: $787.00You Save: $264.39 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Compressor - A/C; A/C Compressor; Compressor A/C

- Replaced by: 5058228AJ

- Replaces: 5058228AE, 5058228AF, R5058228AI, RL058228AI, 5058228AH, 5058228AG

Jeep Compressor - A/C Part Number: 68103198AE

$158.54 MSRP: $232.00You Save: $73.46 (32%)Product Specifications- Other Name: AIR CONDITIONING

- Replaced by: 68103198AF

- Replaces: 68103198AD

Jeep Compressor Part Number: 55371155AD

$191.39 MSRP: $280.00You Save: $88.61 (32%)Product Specifications- Other Name: Compressor - A/C

- Replaced by: 68720019AA

Jeep Compressor - A/C Part Number: 57009910AA

$563.50 MSRP: $851.00You Save: $287.50 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: COMPRESSO-AIR CONDITIONING

Jeep Compressor Part Number: 68346657AD

$164.48 MSRP: $287.00You Save: $122.52 (43%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Compressor - A/C

- Replaced by: 68346657AE

- Replaces: 68346657AB, 68346657AC

| Page 1 of 4 |Next >

1-20 of 62 Results

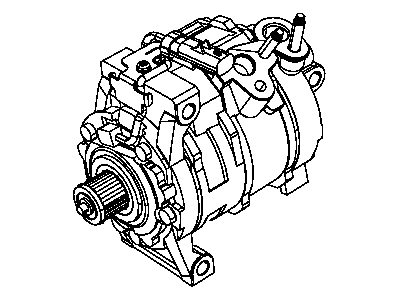

Jeep A/C Compressor

OEM parts sourced directly from Jeep deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Jeep A/C Compressor for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

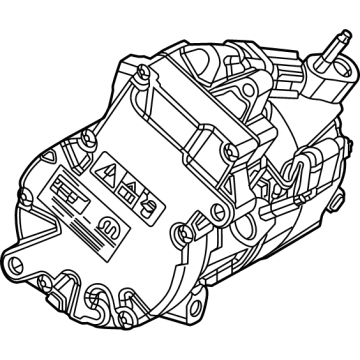

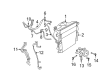

Jeep A/C Compressor uses pressure changes to push refrigerant through to make cabins cool even in atrocious trails. Jeep began civil life in 1945 and soon was the icon of everywhere grit and out-of-doors freedom. At the edges of the pavement, Jeep owners have confidence in steel frames, short overhangs, and the legendary seven-slot grille. Jeep is also loaded with Selec-Terrain switches, voice activation, quick over-the-air software updates, and a friendly neighborhood feel. The lineup strikes a balance that offers suspension travel on the weekends but daily-driving comfort allowing the teens to bring the boards to school or the families to put on the cross-country miles without a hitch. Body panels shake off scrapes, removable roofs welcome sunlight, and plain dashboards help the eyes to be focused on ruts rather than touch screens. The drive modes can be set to switch between snow and sand in seconds, and thus, unexpected weather changes seldom put an end to weekend plans. The A/C Compressor, mounted inside the climate loop, rotates on a clutch-driven pulley, drawing low-pressure vapor through it, forcing it into high-pressure liquid, and expelling that heat out of the firewall to ensure the cabin temperature remains constant as the car crawls along the rocks at low speed or slogs across the state. The output of the A/C Compressor is dependent on an adequate charge of refrigerant; therefore, even a pinhole leak can cause temperatures to run high at an alarming rate. Hear grinding or chatter as the clutch A/C Compressor will tend to tell you before complete seizure that it is ailing. Change the filter-drier, clean the system, and the Jeep cooling loop allows the fresh A/C Compressor to work without a care in the years.

Jeep A/C Compressor Parts and Q&A

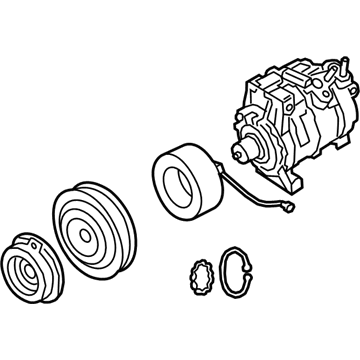

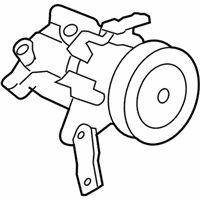

- Q: How to Remove and Replace a Denso A/C Compressor Clutch on Jeep Liberty?A:Place the dowel pin at the back of the compressor clutch field coil into the hole up front of the compressor and secure the field coil in place so that its wire lead isn't squeezed. Secure the compressor clutch field coil with a new snap ring so that the bevel is outside the motor and the eyelets either point toward the right or left side, depending on the position of the dowel pin. Secure the field coil with a snap ring and make sure the ring is seated using pliers for model 9764 or related tools. During pacemaker installation, make certain the friction surfaces are fine and use a snap ring that works with the bevel side outwards. Put a Snap Ring Pliers 9764 or equivalent and insert the snap ring that holds the pulley and bearing assembly securely. Should you reuse the clutch plate and pulley and bearing assembly, fit the original shims on the compressor shaft and if installing new parts, begin with a 2.54 mm stack of shims. Place the clutch plate in the front of the A/C compressor and hold it in place with the compressor shaft bolt, tightened to 19 Nm. Once tightened, examine the air gap at several points and give the pulley a spin before making sure it is correct. For recessed clutch plates, get the air gap measurement with a 90° wire gauge; for others, a blade gauge and 0.35 - 0.60 mm air gap are what you need. Adjust shims so the correct air gap is reached. Run the compressor clutch field coil wire behind the connector bracket, secure the connector onto the bracket and join the engine wire harness. After that, attach the front skid plate, lower the car, fit the accessory drive belt and link the negative battery wire back into the system.