JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 1500 Belt Tensioner

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Belt Tensioners found

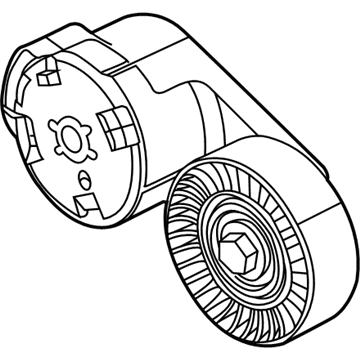

Dodge Ram 1500 Belt Tensioner Part Number: 53030958AG

$88.72 MSRP: $135.00You Save: $46.28 (35%)Ships in 1-2 Business Days

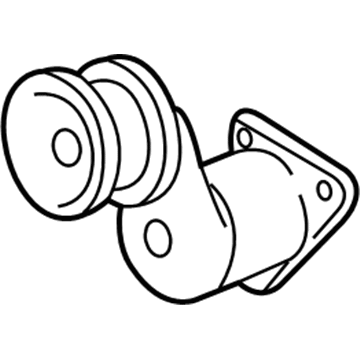

Dodge Ram 1500 Serpentine Tensioner Part Number: 5086500AA

$123.53 MSRP: $184.00You Save: $60.47 (33%)

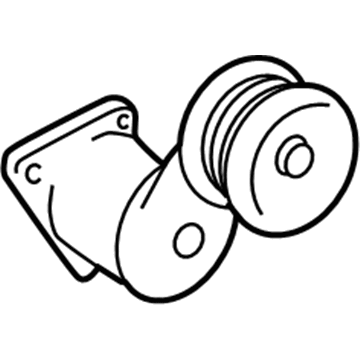

Dodge Ram 1500 Serpentine Tensioner Part Number: 53032130AC

$64.67 MSRP: $96.70You Save: $32.03 (34%)Ships in 1-2 Business Days

Dodge Ram 1500 Belt Tensioner Part Number: 53030958AC

$88.55 MSRP: $136.00You Save: $47.45 (35%)Ships in 1-2 Business Days

Dodge Ram 1500 Belt Tensioner Part Number: 4861660AA

$124.65 MSRP: $188.00You Save: $63.35 (34%)Ships in 1-2 Business Days

Dodge Ram 1500 Serpentine Tensioner Part Number: 53010158AC

Dodge Ram 1500 Serpentine Tensioner Part Number: 53010255

Dodge Ram 1500 Serpentine Tensioner Part Number: 53010240

Dodge Ram 1500 Serpentine Tensioner Part Number: 4762416

Dodge Ram 1500 Serpentine Tensioner Part Number: 53030958AB

Dodge Ram 1500 Serpentine Tensioner Part Number: 53030958

Dodge Ram 1500 Belt Tensioner

Choose OEM Belt Tensioner that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Belt Tensioner follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 1500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 1500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

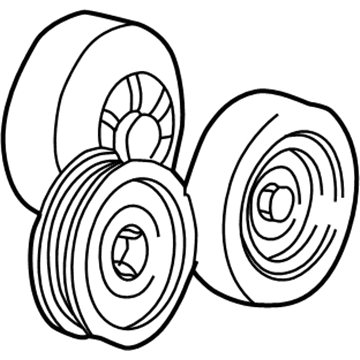

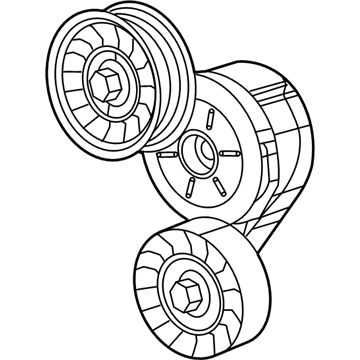

The Dodge Ram 1500 Belt Tensioner is an auxiliary unit that holds a great deal of responsibility in the drive belt system. Belt tensioner: This is a pulley that has a tensioner arm, spring, and base and makes sure the drive belt has the right amount of tension; it eliminates squeaky or grinding noises and such potential failures such as of the alternator or the water pump. The Belt Tensioner models can be installed in the Dodge Ram 1500 model hence making the Belt Tensioner to fit in any model of the trucks as it is a ready made option to help in boosting the performances and alarming systems of the trucks. The Belt Tensioner must be checked frequently, and appropriate maintenance must be made since it may cause severe issues in the operation. The Dodge Ram 1500 is known for its workability and durability and the performances of the Belt Tensioner are not the exception when speaking about this significant feature. In particular, the Dodge Ram 1500 Belt Tensioner marked in the automotive market as exceptionally robust and capable to drive regardless of demanding conditions. The inclusion of modern features over the years by Dodge affects the Ram 1500 as a very strong contender in the full size pick up truck market. In conclusion, the Dodge Ram 1500 Belt Tensioner is not just a product but a significant functional element that allows the consumers to depend on their trucks at the job site or anywhere else.

Dodge Ram 1500 Belt Tensioner Parts and Q&A

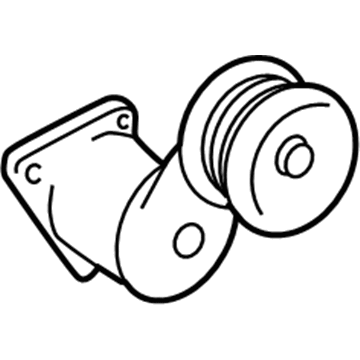

- Q: How to Service a Belt Tensioner on Dodge Ram 1500?A:Before servicing the Drive Belt tensioner, unfasten the accessory belt and also remove the wiring and secondary cable from the Ignition Coil. Then, remove the ignition coil from its mounting bracket using the right size bolts, so you don't disconnect the mounting bracket from the cylinder head. Right after, take a nut off the mounting bracket and then remove the tensioner pulley bolt and pulley from the tensioner. The first step of installation is to attach the pulley and bolt to the tensioner and tighten the bolt until it reaches 61 Nm (45 ft. lbs.) torque. After that, place the tensioner assembly back on the mounting bracket, making sure the tab at the rear of the tensioner aligns with the slot in the bracket and secure it with 67 Nm (50 ft. lbs.) torque on the nut. Afterwards, make sure all wires are properly connected to the ignition coil and tighten the bolts that secure the coil so it doesn't break its case. If you're using nuts and bolts, install the coil and tighten it to 11 Nm (100 in. lbs.); if the bracket is tapped, tighten to 5 Nm (50 in. lbs.). Attach the drive belt again and make sure you match the belt indexing marks correctly.

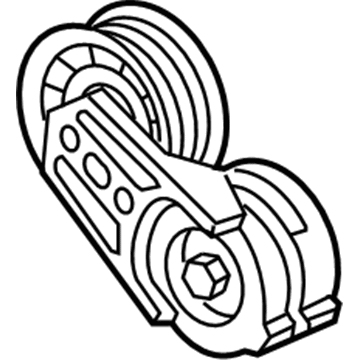

- Q: How to Install a Belt Tensioner on 3.7L and 4.7L Engines on Dodge Ram 1500?A:For these two engines, before fitting the new belt, the indexing stop on the end of the tensioner should be about 24 mm (0.94 inches) from the indexing tang on the engine housing. If the standard is not reached, look at the belt, because the length or width might be incorrect or check the A/C Compressor, Power Steering Pump, Water Pump, idler pulley or generator for worn bearings. You should replace a belt once the tensioner indexing arrow arrives at the lowest tension reading, because the tensioner stops at this point in its movement. First, take off the accessory Drive Belt, then disconnect the tensioner assembly from its bracket. The high pressure in spring stops you from taking apart the automatic tensioner; it only needs the pulley serviced. After that, remove the pulley bolt and the pulley from the tensioner. To mount the pulley and bolt on the end of the tensioner, tighten the bolt to 61 Nm or 45 ft. lbs. Position the tensioner's screw on the back in line with the bolt head on the front cover, fit and tighten the mounting bolt to 41 Nm (30 ft. lbs.). Then, set up the accessory drive belt and check where the belt indexing marks line up.