JeepParts

My Garage

My Account

Cart

OEM Dodge Sprinter 3500 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Oil Pans found

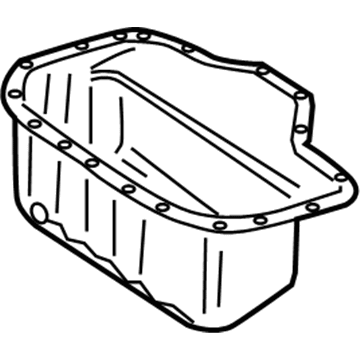

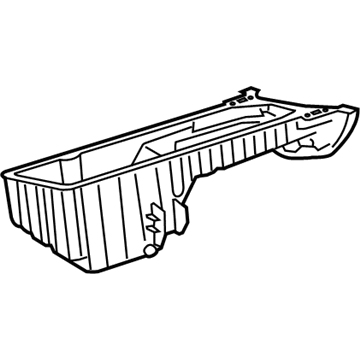

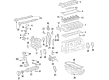

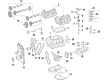

Dodge Sprinter 3500 Oil Pan, Lower Part Number: 68006079AA

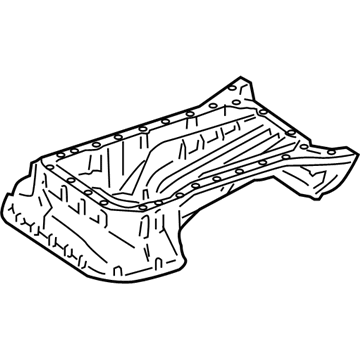

Dodge Sprinter 3500 Oil Pan, Upper Part Number: 68047503AB

Dodge Sprinter 3500 Oil Pan, Lower Part Number: 68013881AA

Dodge Sprinter 3500 Oil Pan, Upper Part Number: 68013877AA

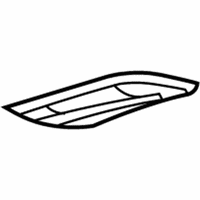

Dodge Sprinter 3500 Tray Part Number: 5117250AA

Dodge Sprinter 3500 Oil Pan Part Number: 5117152AA

Dodge Sprinter 3500 Oil Pan

Choose OEM Oil Pan that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Oil Pan follows strict manufacturing steps to lock in quality and fit. If your Dodge Sprinter 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Sprinter 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Sellant Dodge Sprinter 3500 Oil Pan is extremely vital and plays a great role to the strength of the Dodge Sprinter 3500 car models. Being a housing for engine oil, the oil pan is an important component of the various engines and performs the function of holding the oil that is supposed to lubricate and cool the various mechanical parts that are in contact within the engine. Due to the varying nature of demands put on its carriers, the Dodge Sprinter 3500 Oil Pan is typically made out of cast aluminum; this increases its durability and ability to withstand the test of time. Eligibility for 2003-2009 Dodge Sprinter 3500 demonstrates versatility in fitting various engine types such as 2.7L I5 and the 3.0L turbodiesel V6. The function of this oil pan remains not only to produce a higher level of efficiency in the engine but also to contribute to the safety of a car by managing the oil levels and its possible consequences that can impact the engine. Most notably, the Dodge Sprinter 3500 Oil Pan is prominently distinct from other automotive products that can be purchased in the market since it has a powerful framework that enhances fuel economy of around 25 mpg together with towing capacity of approximately 5,000 pounds. In summing up, the Dodge Sprinter 3500 Oil Pan reflects the company's quality and performance standards and therefore a vital component of the Dodge Sprinter 3500 vehicle.

Dodge Sprinter 3500 Oil Pan Parts and Q&A

- Q: How to Service and Repair an Oil Pan on Dodge Sprinter 3500?A:The first step in working on the oil pan is to drain the engine oil. Take out the retaining bolts from the sway bar and then swing the sway bar to one side, lifting it out of the way. Take the wiring harness duct off the oil pan bolts and place it near your car. Lift the car up again and take off the heat shield found on the upper part of the turbocharger. Use #8534-16 adapters to bolt engine support fixture #8534 to the engine's lifting eye and gently lift it. Take out the Engine Mounts and lift the engine up a little more. Take out the transmission cooler lines from the oil pan bolts and afterwards, unplug the oil level sensor. First, remove the oil pan bolts and then remove the oil pan and the gasket underneath. After fitting the parts, be sure to reinstall the oil pan bolts where you first unscrewed them, since they are not all the same diameter or length. Rinse your Oil Pump's strainer, add clean engine oil if there's not enough and use the recommended solvents to clean greasy parts. Fit the oil pan gasket, applying sealant to the suggested spots and then set the oil pan in place, fastening M6 bolts to 9 Nm (80 inch lbs.) and M8 bolts to 20 Nm (15 ft. lbs.). Tighten the transmission bell housing bolt to the oil pan to a value of 40 Nm (30 ft. lbs.). Reinstall the wiring harness duct and transmission lines and then put in the oil level sensor. Drop the vehicle and engine so the buckets and the engine mount make contact and then start with the engine mount bolts. Pull the engine down as much as you can and release the hook holding it, followed by tightening the engine mount bolts to 83 Nm (61 ft. lbs.). Attach the sway bar again and tighten its bolts to 30 Nm (22 ft. lbs.), put the correct engine oil into the crankcase and link the negative Battery Cable back up. Hold handles properly and stay away from anything moving such as pulleys, belts or the fan, when the engine is working and don't wear loose garments. When you've finished, start the car and check it for any leaks.

- Q: How to Maintain and Fix an Oil Pan on Dodge Sprinter 3500?A:The first thing to do when servicing or repairing an oil pan is to disconnect the negative Battery Cable. After that, take out the accessory belt before handling the transmission. When you're done, lift out the flex plate and take out the 5 bolts that hold the rear main seal carrier in place. For the last part, remove the bolts from the oil pan and take out the pan.