JeepParts

My Garage

My Account

Cart

OEM Jeep Cherokee Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Oil Pans found

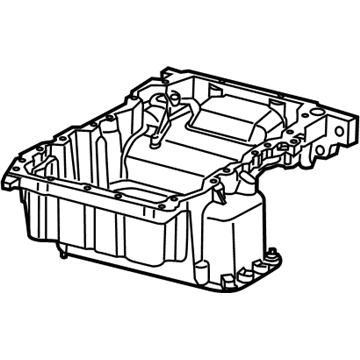

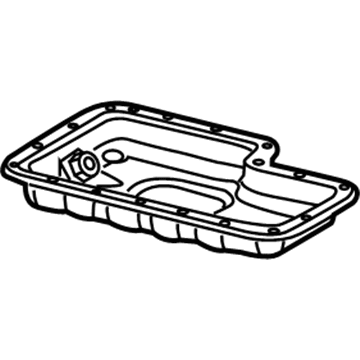

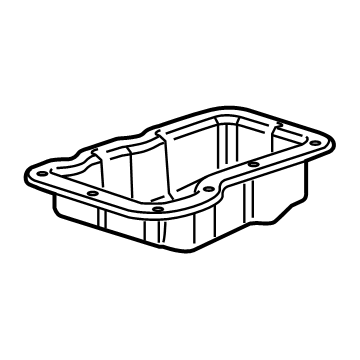

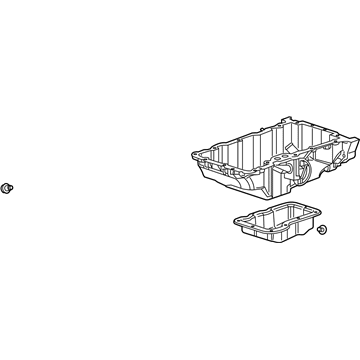

Jeep Cherokee Oil Pan, Upper Part Number: 68161415AA

$206.21 MSRP: $308.00You Save: $101.79 (34%)Ships in 1-2 Business Days

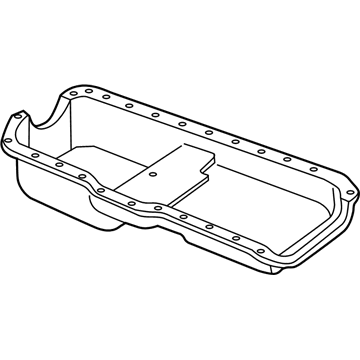

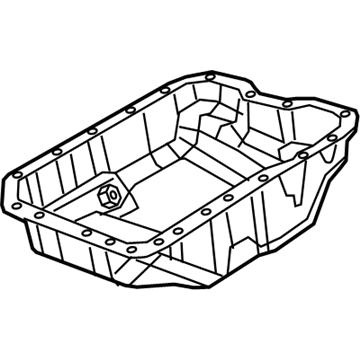

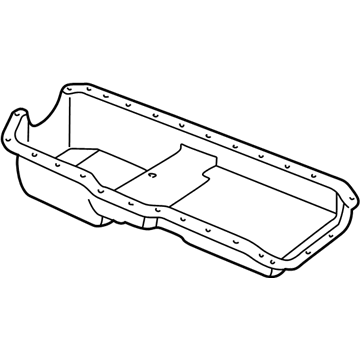

Jeep Cherokee Oil Pan Part Number: 53020833AB

$352.66 MSRP: $519.00You Save: $166.34 (33%)Ships in 1-2 Business Days

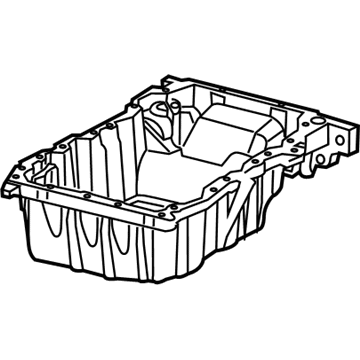

Jeep Cherokee Oil Pan Part Number: 68086157AC

$218.67 MSRP: $326.00You Save: $107.33 (33%)Ships in 1-2 Business DaysJeep Cherokee Oil Pan Part Number: 4893545AB

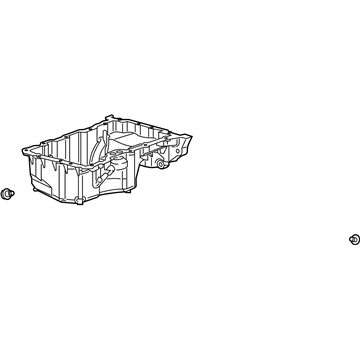

$256.06 MSRP: $376.00You Save: $119.94 (32%)Ships in 1-2 Business DaysJeep Cherokee Oil Pan, Lower Part Number: 68161420AB

$48.28 MSRP: $70.95You Save: $22.67 (32%)Ships in 1-2 Business DaysJeep Cherokee Oil Pan Part Number: 5047566AE

$167.68 MSRP: $252.00You Save: $84.32 (34%)Ships in 1-2 Business Days

Jeep Cherokee Oil Pan Part Number: 53020831

Jeep Cherokee Oil Pan Part Number: J3243152

Jeep Cherokee Oil Pan Part Number: J3243140

Jeep Cherokee Oil Pan Part Number: 53020560

Jeep Cherokee Oil Pan Part Number: 53020108

Jeep Cherokee Oil Pan Part Number: 5048407AB

Jeep Cherokee Oil Pan Part Number: 5048405AB

Jeep Cherokee Oil Pan

Choose OEM Oil Pan that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Oil Pan follows strict manufacturing steps to lock in quality and fit. If your Jeep Cherokee matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cherokee parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Oil Pan used in Jeep Cherokee vehicles acts as a receptacle for engine oil to make sure all erasing parts of the vehicle engine are well lubricated and cooled. In a wet sump system basically seen in most Jeep Cherokee models, the Oil pan holds oil drawn through the Pickup tube by the oil pump and circulates the oil around the engine before it falls back into the pan. For the overall operation of the engine, this design is suitable in making sure that there is a steady flow of oil at different operating conditions. An earlier range of Jeep Cherokee Oil Pans was mostly constructed from stamped steel while the current generation product involved cast aluminum to offer a higher performance standard. Despite undergoing change, it's evidenced that the basic function fails to change and is only subject to reflection of advanced engine design and performance.

Jeep Cherokee Oil Pan Parts and Q&A

- Q: How to Properly Maintain and Fix an Oil Pan on a Jeep Cherokee?A:Before servicing the oil pan, unplug the negative battery cable and lift the vehicle. Take out the oil drain plug from the oil pan, connect a garden hose to the drain port in the engine and remove the Exhaust Pipe at the engine and the exhaust hanger at the Catalytic Converter. Take the engine Starter Motor and the access cover from the Flywheel/torque converter housing out. Place a jack stand under the engine vibration damper, with a piece of 2 x 2 wood acting as a spacer and unbolt the Engine Mounts. Lift the engine high enough with the jack stand that you can remove the oil pan. If it makes sense, unhook the transmission cooler lines and oxygen sensor harness from the oil pan studs and then detach the oil pan bolts and studs. Afterward, carefully take off the oil pan and the gasket by lifting the pan out. Wash or wipe the block and pan gaskets and then carefully make four alignment dowels out of 1/4 by 1/2 inch bolts. Put two dowels in the timing case cover and the other two in the cylinder block. Put Mopar Silicone Adhesive Sealant on the cylinder block where it is marked in the instructions, then put the gasket onto the dowels and cover the block and timing cover. Lower the oil pan onto the dowels and the gasket as a set, installing both buckets of bolts in a cross pattern. Once in place, tighten the bolts by hand before using a torque wrench to tighten them by 9.5 Nm (84 In. lbs.) for the smaller bolts and 15 Nm (132 In. lbs.) for the larger bolts. Remove the dowels and insert the last four 1/4 inch oil pan bolts, tightening them all to 9.5 Nm (84 In. lbs.). Carefully lower the engine down onto the mounts, put in the through bolts and secure them with nuts and finally pull the jack stand and lift the wood off. The next step is to replace the flywheel and torque converter housing cover and then the engine starter motor. Link the exhaust pipe back to the hanger and engine Exhaust Manifold and then install the oil pan drain plug, turning it until you reach 34 Nm (25 Ft. lbs.) of torque. Lift the vehicle, secure the negative cable back to its place and put the right quantity of oil into the engine oil pan. When the engine is on, stay well away from the fan and don't stand directly between it and the pulleys or belts, also avoiding loose clothing. Start the vehicle and look for any leaks before the next step.

- Q: How to Service and Repair an Oil Pan on Jeep Cherokee?A:To work on or repair the oil pan, disconnect the negative battery cable and lift up your vehicle first. Fist, get rid of the engine oil by taking out the oil pan drain plug. Then take out the pipe from the Exhaust Manifold and hang it up using the Catalytic Converter to lower it. Take out the Starter Motor, engine Flywheel and the cover on the transmission torque converter housing. If an oil level sensor can be found, unplug it. Set a jack stand under the engine vibration damper, with a piece of 2 x 2 wood between them, then undo the bolts that hold the Engine Mount and raise the engine to allow you to remove the oil pan. Pull out the transmission oil cooling lines and Oxygen Sensor wiring supports attached to the oil pan, then undo the oil pan bolts and studs, pulling the oil pan and gasket to the back while making sure the oil level sensor isn't damaged. To install the block and pan gasket, clean the surfaces, cut four 1 1/2 x 1/4 inch dowels from bolts and fit two in the timing case cover and two in the block. Coat the Mopar Silicone Rubber Adhesive Sealant on the cylinder block where it meets the back of the rear main bearing cap and also over the bottom of the cylinder block where the front cover is installed, then slide the gasket onto the block and timing case cover dowels. Line up the oil pan over the dowels and gasket, making sure the sensor sticks are not damaged if your engine has a sensor. Before the others, tighten the 1/4 inch oil pan bolts to 9.5 Nm (84 in. lbs.) and then tighten the 5/16 inch oil pan bolts to 15 Nm (132 in. lbs.). Remove the dowels, insert the eight remaining 1/4 inch oil pan bolts and fasten them to 9.5 Nm (84 in. lbs.). Lay the engine onto the engine mounts, add the through bolts, secure the nuts and lower the jack stand to get rid of the piece of wood. After that, put the flywheel back into place and next reinstall the access cover and the starter motor. Hang the Exhaust Pipe again from the hanger and ensure it fits the engine exhaust manifold. After that, add the transmission oil cooling lines and oxygen sensor wiring supports. Install the oil pan drain plug and make sure it's tightened to 34 Nm (25 ft. lbs.), then lower the vehicle, hook the negative cable back onto the battery and fill the oil pan to its correct level. Turn on the engine, then carefully examine it for leaks, being extra careful around the running engine, away from the fan and away from any pulleys or belts on your hands.