JeepParts

My Garage

My Account

Cart

OEM 2006 Jeep Liberty Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Brake Booster found

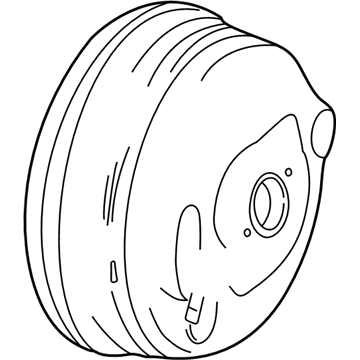

2006 Jeep Liberty Brake Booster Part Number: 5134120AA

Product Specifications- Other Name: Booster - Power Brake; Power Brake Booster; Power Booster; Booster Power Brake

- Item Weight: 7.90 Pounds

- Item Dimensions: 10.8 x 10.5 x 10.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5134120AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Jeep Liberty Brake Booster Parts and Q&A

- Q: How to Service and Repair a Vacuum Brake Booster on a Left-Hand Drive on 2006 Jeep Liberty?A: Before working on the vacuum brake booster on a left-hand drive vehicle, cut the wire to the fluid level switch found at the reservoir's bottom and then take out the master cylinder. After that, pull out the vacuum pipes from the booster check valve and let the brake lines out of the master cylinder and HCU so that you have more space. Lift off the protective HCU cables and slide the unit away, then remove the knee blocker and brake light switch before throwing the switch into the debris pile. Take out the retaining clip holding the push rod to the brake pedal and unscrew the nuts that hold the booster to the dash board. On the dashboard side of the engine compartment, take out the booster studs, raise the booster and lift it out. When installing the booster, set it on the dash and fix the mounting nuts in place. Apply a ring of grease to the Mopar multi-mileage grease on the pedal pin and then attach the booster push rod to the brake pedal and hold it together with the retaining clip. Raise the bolts for the booster to 25 Nm (220 inch lbs.), attach a new brake lamp switch and connect the cable to the electrical connector. Put the knee blocker back in its place and if the seal at the rear of the master cylinder is being reused and is damaged, switch the seal out. Clean the brake booster's cylinder mounting area with a damp, shop towel and brake cleaner to make sure it fits tightly and does not leak brake pressure. After aligning it, bolt the master cylinder onto the booster studs, Ross then tighten the mounting nuts to 25 Nm (220 inch lbs.). Join the hose to the booster check valve, replace the HCU and set the screws on the bracket to 125 inch lbs. Link the brake line from the HCU or junction block to both ends of the master cylinder, manually starting every brake bolt to ensure you don't cross-thread it. After that, plug the wire back into the fluid level switch at the reservoir's bottom, finish filling and bleeding the basic brake cylinders and check the brakes are working as expected.