JeepParts

My Garage

My Account

Cart

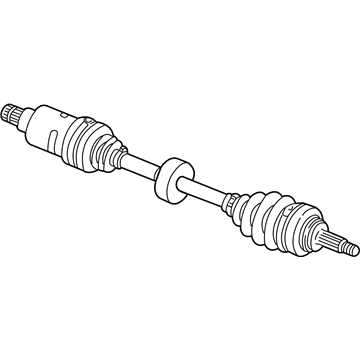

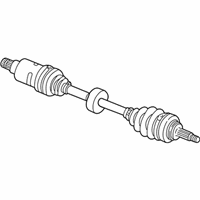

OEM Dodge Neon Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Axle Shafts found

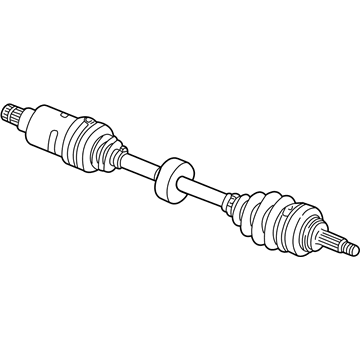

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 4668936AC

$362.56 MSRP: $544.36You Save: $181.80 (34%)Ships in 1-2 Business Days

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 5286710AE

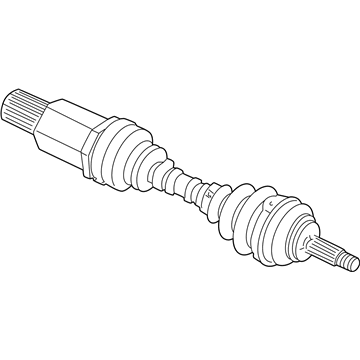

Dodge Neon Axle Assembly, Front Driver Side Part Number: RL037623AA

Dodge Neon Axle Assembly, Front Driver Side Part Number: 5274711AF

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 4668956AE

Dodge Neon Axle Assembly, Front Driver Side Part Number: 4668953AD

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 4668952AF

Dodge Neon Axle Assembly Part Number: 4668800AB

Dodge Neon Axle Assembly, Front Driver Side Part Number: 4668421AC

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 4668420AC

Dodge Neon Axle Assembly Part Number: 4670607AB

Dodge Neon Axle Assembly, Front Driver Side Part Number: 4668915AA

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 4668914AA

Dodge Neon Axle Assembly, Front Passenger Side Part Number: 5037622AA

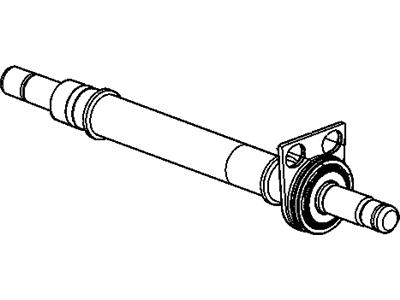

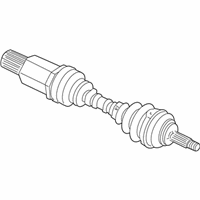

Dodge Neon Intermediate Shaft Part Number: 5037341AA

Dodge Neon Axle Shaft

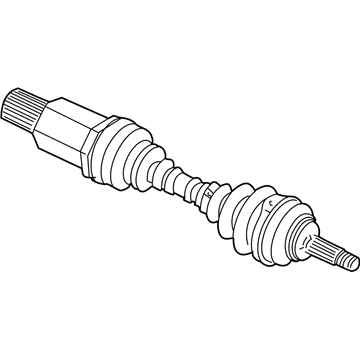

Choose OEM Axle Shaft that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Axle Shaft follows strict manufacturing steps to lock in quality and fit. If your Dodge Neon matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Neon parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

In Dodge Neon, the Axle Shaft is very important since it connects the differential to the drive wheel shafts which allows the wheels to rotate at different speeds when the car is cornering. Most of the time, these axle shafts are of steel and the primary requirement for them is to endure the thrust load, help in keeping the wheel in a proper position as well as take the weight of the vehicle. Dodge Neon models apply halfshafts, and one of its parts is splined ends that connect the halfshaft with the differential and wheel hub. This design enables the suspension system to be independent, and as a results improves the quality of the ride. Over the years, variations in axle shaft configurations may have occurred, but the fundamental purpose remains consistent: to help in connection of power of the train and to aid the dynamic behaviour of the train system in question. The most important thing is the correct replacement frequency, worn elements of which contribute to noise and vibration, and even the failure of the axle shafts on Dodge Neon automobiles.

Dodge Neon Axle Shaft Parts and Q&A

- Q: How to Remove and Reinstall an Axle Shaft on Dodge Neon?A:First, get the transaxle into gated park, disconnect the negative Battery Cable and then place the vehicle on the hoist. Loosen the wheel and tire through the hub, then remove the halfshaft to hub cotter pin, nut lock, wave washer and hub nut. Should the vehicle have ABS, be sure to remove the front wheel Speed Sensor and run the wire out of the way beneath the car. Take out the retaining bolt and nut holding the ball joint stud to the Steering Knuckle, while not damaging the seal as you separate the ball joint stud from the steering knuckle by pushing down the lower part of the Control Arm. Make sure the inner C/V joint is still joined together during this procedure and use support for the halfshaft. To remove the halfshaft from the steering knuckle, press in on the halfshaft while pulling the knuckle away from the engine, using Puller 1026 if found necessary. Support the outer end of the halfshaft, then punch the inner tripod joints from the transaxle side gears to take out the retaining ring. Place the punch against the right side joint and hit it with a hammer and position it in the left side groove and hit it too. Grab the inner tripod and its interconnecting shaft, then gently remove the halfshaft assembly from the transaxle gear and seal without touching the spline or snap ring to the sealing lip. Some fluid will come out when you remove the joint on the tripod. Wipe both sides of the spline and oil seal sealing area on the tripod joint, coat them lightly with fresh and clean transmission lubricant and place the joint inside the transaxle side gear by hand. Put the tripod joint into the side gears and push it in so the snap ring catches. Clean all dirt and moisture from the steering knuckle and front of the outer C/V joint before sliding half the shaft in and fixing the knuckle onto the ball joint stud. Fit a PMW steering knuckle to the ball joint stud bolt and nut, tightening to 95 Nm (70 ft. lbs.), afterwards clean the threads on the halfshaft outer stub axle and secure the hub nut with 244 Nm (180 ft. lbs.) of torque. After installing the front wheel and tire, screw on the lug nuts to 128 Nm (95 ft. lbs.), inspect the fluid in the transaxle assembly, lower the vehicle and connect the battery's negative cable.

- Q: How to Service and Repair an Axle Shaft on Dodge Neon?A:To fix or repair the axle shaft, first confirm the sealing boot is secured to keep the lubrication inside and out any dirt, properly support the driveshaft so it isn't damaged during each step and replace it from each end. Remove the battery negative cable, put the transaxle in gated park and lift the vehicle with a hoist. After taking off the wheel, separate the tire from the assembly and then take the driveshaft to hub and bearing retaining nut off. If the system has ABS, you should remove the front wheel speed sensor and fasten the harness. Take out the nut and bolt holding the ball joint stud in the Steering Knuckle without hurting the seal. Take out the ball joint stud after prying down on the lower Control Arm and checking that the ON joint remains together. While pushing in on the driveshaft, slowly pull it out of the steering knuckle; if the removal is tough, insert Special Tool 6790 to separate the driveshaft's outer stub axle from the hub and bearing assembly. Support the outer end of the driveshaft assembly and then tap those retaining rings out of the transaxle side gears using a punch. Hold onto the tripod joint and interconnecting shaft together, then pull directly on the tripod joint, letting it slide straight out of the transaxle's side gear and oil seal which will allow some oil to spill out. Wipe out the area inside the tripod joint, use only a little fresh gear oil and tighten the tripod joint into the side gear by hand so the snap ring locks correctly. Clean the steering knuckle and the area of the outer C/V joint and then slide the driveshaft back into the hub and attach the steering knuckle to the ball joint stud. Install a ball joint on the new steering knuckle, hold it tightly using the bolt and nut and tighten both to 95 Nm (70 ft. lbs.). After that, remove any dirt from the outer axle's threads and add a new outer axle hub nut, tightening it to 244 Nm (180 ft. lbs.). Set the lug nuts on the front wheel and tire to 128 Nm (95 ft. lbs.), inspect the transaxle fluid, drop the vehicle and connect the negative cable of the battery.