JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 2500 Lash Adjuster

Lash Adjuster Lifter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Lash Adjusters found

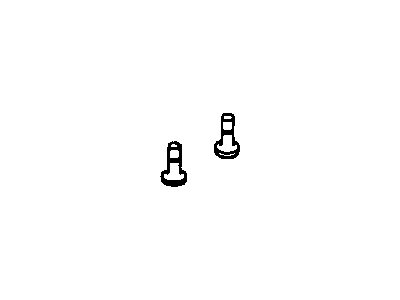

Dodge Ram 2500 Valve Lifters Part Number: 5038787AD

$81.47 MSRP: $109.00You Save: $27.53 (26%)

Dodge Ram 2500 Valve Lifters Part Number: 5038784AD

$152.73 MSRP: $229.00You Save: $76.27 (34%)Dodge Ram 2500 Valve Lifters Part Number: 5086736AA

$53.81 MSRP: $79.00You Save: $25.19 (32%)Ships in 1-2 Business Days

Dodge Ram 2500 Valve Lifters Part Number: 4713439

Dodge Ram 2500 Valve Lifters Part Number: 5011790AA

Dodge Ram 2500 Valve Lifters Part Number: 5003595AA

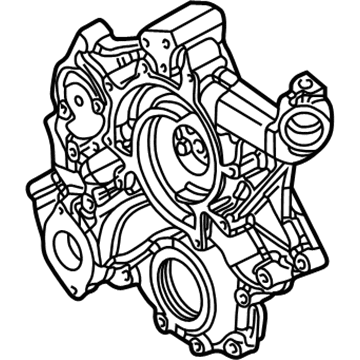

Dodge Ram 2500 Lash Adjuster

Choose OEM Lash Adjuster that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Lash Adjuster follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 2500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 2500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 2500 Lash Adjuster Parts and Q&A

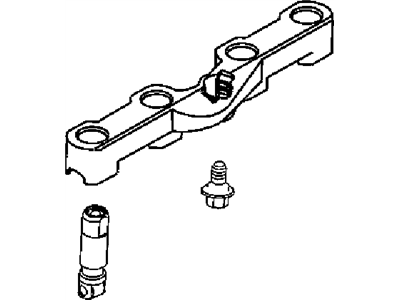

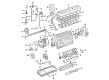

- Q: How Does a Lash Adjuster Contribute to Fuel Economy and What Are Its Installation Requirements on Dodge Ram 2500?A:Making use of the MDS, the engine helps to improve fuel economy when operating at steady speeds, while accelerating slowly or traveling up a small incline. MDS engines are able to use standard roller tappets, but use deactivating roller tappets in cylinders 1, 4, 6 and 7, as indicated by the two holes on the side for the latching pins. You should always fit the guide holder and tappets together and in their normal position for a safe engine. Lubrication should always begin with the tappet guide holder and tappets. In case you are recycling the tappets and guide holder assembly, put them back in their exact position. After that, place the tappet guide holder and tappets on the engine and tighten the retaining bolt to 12 Nm (9 ft. lbs.). After that, fit the cylinder head and then attach the negative cable to the battery. To ensure the valve assembly is safe, run the engine at fast idle only after all of the lash adjusters are lubricated and have fallen silent. After that, fire up the engine, look for any signs of fluid leaking and test the vehicle for 15 minutes on the road.

- Q: How to Service and Repair a Lash Adjuster on Dodge Ram 2500?A:To work on the lifter and lash adjuster, start by taking off the negative cable from the battery. After that, take out the air cleaner housing (3) and then the Intake Manifold. After the cylinder head cover is removed, uninstall the Rocker Arm assembly and the push rods and be sure to find which push rods go where during reinstallation. Next, detach the cylinder head and remove the bolt from the tappet retainer (1) and only then take out the tappet retainer (1). Grasp the tappet and twist it out of the bore; if all tappets are saved, be sure to label them so they go back where they belong when you reinstall. In addition, examine the camshaft lobes to ensure there is no abnormal wear.