JeepParts

My Garage

My Account

Cart

OEM Dodge Stratus Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Intake Manifolds found

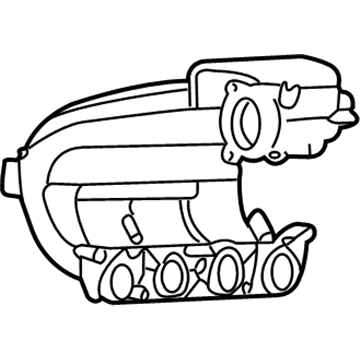

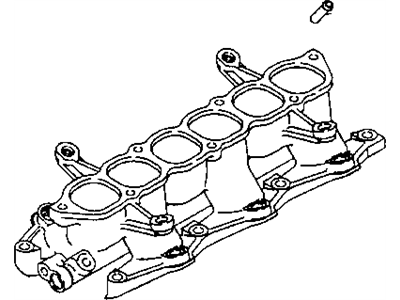

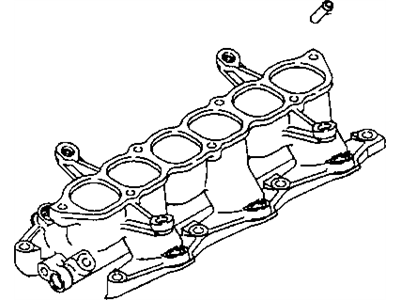

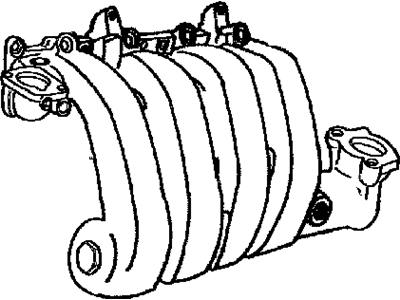

Dodge Stratus Intake Manifold Part Number: 4792432AG

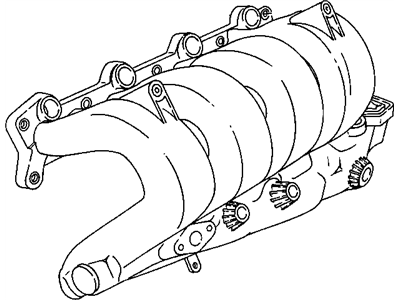

$143.62 MSRP: $182.07You Save: $38.45 (22%)Ships in 1-2 Business DaysDodge Stratus Intake Manifold, Upper Part Number: 4792596AG

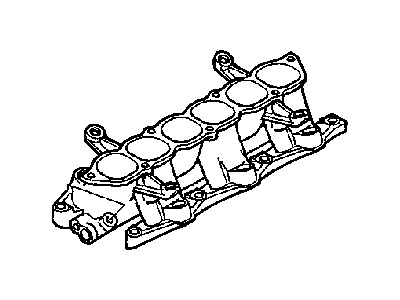

$157.87 MSRP: $302.00You Save: $144.13 (48%)Ships in 1-2 Business Days

Dodge Stratus Intake Manifold Part Number: MD354398

Dodge Stratus Intake Manifold Part Number: MD333780

Dodge Stratus Intake Manifold Part Number: MD309078

Dodge Stratus Intake Manifold Part Number: 4856614AB

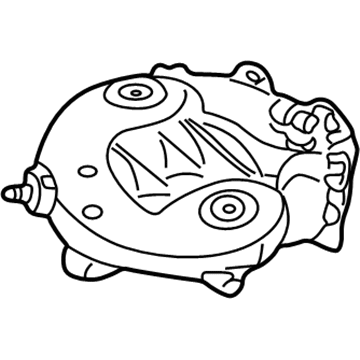

Dodge Stratus Intake Plenum Part Number: 4792596AJ

Dodge Stratus Intake Manifold Part Number: 4792432AD

Dodge Stratus Intake Manifold Part Number: 4792209

Dodge Stratus Intake Manifold Part Number: 4792183

Dodge Stratus Intake Manifold, Upper Part Number: 4593539AA

Dodge Stratus Intake Manifold, Lower Part Number: 4591273AB

Dodge Stratus Intake Manifold

Choose OEM Intake Manifold that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Intake Manifold follows strict manufacturing steps to lock in quality and fit. If your Dodge Stratus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Stratus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Intake Manifold is one of the best performing parts that play a very crucial role in boost up the capability of Dodge Stratus car models. Intended to provide air or air/fuel mixture to each cylinder head intake port they are major components that enable optimization of the engines' power. Usually made of lightweight plastic it allows better heat dispersion more contributing to the efficiency of Dodge Stratus. This Intake Manifold is applicable to different Stratus models, the first generation and the second generation, their engines ranging from 2.0L I4 to 3.0L V6. Indeed some models of Intake Manifold may include coolant passages and sensor that measures and detects the temperature and air charge for security and efficiency. Consequently, variable-length designs enable precise adjustments of the flow speed and pressure and thus the engine efficiency under load variation. It also increases horsepower and torque for a more powerful car on the road; this action also makes sure that the Dodge Stratus remains as a reliable car in the market today. Thus, the intake manifold used in the Dodge Stratus is different from other cars by its design elements and engineering; it remains one of the highlights of the automotive market because it caters to drivers involved in performances while at the same time creating efficiency. All in all, the Intake Manifold best represents the brand's characteristic of providing a luxurious driving experience together with safety and reliability for all the Stratus models.

Dodge Stratus Intake Manifold Parts and Q&A

- Q: How to Properly Service and Install an Intake Manifold on Dodge Stratus?A:Before you start on the intake manifold, make sure fuel system pressure is released and that the surroundings are well ventilated and away from anything that could cause ignition. After unlinking the negative cable from the auxiliary jumper terminal, take the air inlet resonator out. Clear out the fuel system pressure by following the procedure and afterwards disconnect the fuel supply line quick connect from the Fuel Rail assembly, holding shop towels around the line to catch any leaking gasoline. Loosen the attaching screws of the fuel rail assembly and use something to cover the injector holes, making sure not to set the Fuel Injectors on their tips. Remove the connectors for the accelerator and speed control, for the Idle Air Control (IAC), Throttle Position Sensor (TPS) and finally the intake air connector. You should also unplug the leak detection pump and PCV hoses, the Knock Sensor's electrical connection and the wiring harness at the tab on the intake manifold. Take out the transaxle to Throttle Body support bracket bolts and release the bolt at the rear transaxle end. Unscrew the bolts for the EGR Tube at the valve and the intake manifold, remove the old gaskets and lift out the intake manifold from its spot on the inlet water tube support. Next, get rid of the intake manifold fasteners and washer assemblies to pull out the manifold. Once installation begins, change all O-ring seals and take out the old manifold screws and their washers, replacing them with new ones. Install the fresh O-ring seals and lock the bolts with a torque of 12 Nm (105 in. lbs.) as directed. After taking off the cover on the fuel injector holes and cleaning them, put the fuel rail assembly into the intake manifold and tighten the screws to 23 Nm (200 in. lbs.). Join the PCV and brake booster hoses, look for damage in the quick connect fittings, apply a light layer of engine oil to the tube and connect the fuel supply hose to the fuel rail assembly, verifying the connection with a pull on the connector. After setting the throttle body, torque its fasteners to 22 Nm (200 in. lbs.); then, fit the transaxle to the throttle body bracket by tightening the screw at the throttle body first and then at the bracket at the transaxle, to 12 Nm (105 in. lbs.). Attach the MAP, intake air temperature sensor, knock sensor and starter relay wiring connectors together. Wrap the wiring harness around the intake manifold tab and link the IAC motor and TPS connectors to the sensors. At this point, put the vacuum hoses on the throttle body and join the accelerator and speed control cables to their bracket and throttle lever. Once you've installed the new EGR gaskets, gently fit the EGR tube onto the valve and manifold and tighten the fasteners at the EGR valve to 11 Nm (95 in. lbs.) and then those at the manifold to 11 Nm (95 in. lbs.). After this, attach the negative cable to the auxiliary jumper terminal and then use the DRB scan tool for the ASD Fuel System Test, turning on the ASD relay for either 7 minutes or until you shut down the test by other means or switch the ignition off.