JeepParts

My Garage

My Account

Cart

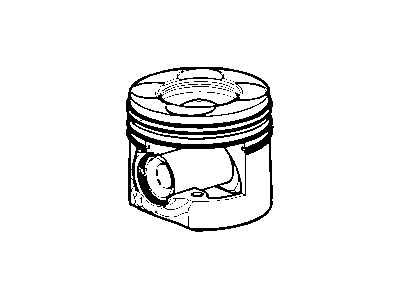

OEM Jeep Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

60 Pistons found

Jeep Piston Part Number: 68147230AA

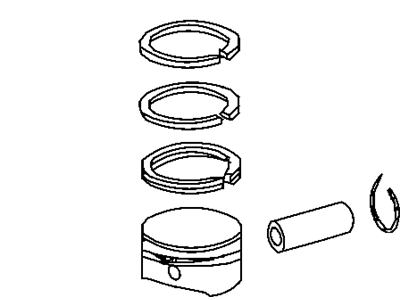

$356.10 MSRP: $522.00You Save: $165.90 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine Includes Piston Rings

Jeep Piston Part Number: 68210587AA

$88.10 MSRP: $131.00You Save: $42.90 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine A Grade .1Mm Outside

Jeep Piston Part Number: 5179423AC

$130.17 MSRP: $825.00You Save: $694.83 (85%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Pin And Rings .50mm O/S; Piston Pin And Rings .50Mm Outside

- Replaces: 5179423AB, 5179423AA, 68034930AA

Jeep Piston Part Number: 68439095AA

$109.83 MSRP: $165.00You Save: $55.17 (34%)Product Specifications- Other Name: Piston - Engine; Piston Engine B Grade

Jeep Piston Part Number: 68210586AA

$105.67 MSRP: $160.00You Save: $54.33 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine C Grade

Jeep Piston Part Number: 68210585AA

$163.96 MSRP: $244.00You Save: $80.04 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine B Grade

Jeep Piston Part Number: 5191339AA

$102.24 MSRP: $136.00You Save: $33.76 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - C - Size; Piston Pin And Rod C - Size See Note; Piston Pin And Rod C - Size

Jeep Piston Part Number: 68067507AA

$206.24 MSRP: $237.00You Save: $30.76 (13%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 4778855AB, 4778859AB, 4778857AB

Jeep Piston Part Number: 68210584AA

$143.74 MSRP: $216.00You Save: $72.26 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine A Grade

Jeep Piston Part Number: 5191338AA

$130.19 MSRP: $184.00You Save: $53.81 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - B - Size; Piston Pin And Rod B - Size See Note; Piston Pin And Rod B - Size

Jeep Piston Part Number: 68086046AB

$105.19 MSRP: $134.00You Save: $28.81 (22%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 68086046AA

Jeep Piston Part Number: 4798329AC

$138.85 MSRP: $200.00You Save: $61.15 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston Pin And Rod; Piston Pin And Rod

Jeep Piston Part Number: 5142544AB

$66.37 MSRP: $381.00You Save: $314.63 (83%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 5142544AA

Jeep Oil Pump Part Number: 5191337AA

$102.41 MSRP: $212.00You Save: $109.59 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - A - Size; Piston; Piston Pin And Rod A - Size See Note; Piston Pin And Rod A - Size

Jeep Piston Part Number: 68210588AA

$110.33 MSRP: $166.00You Save: $55.67 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine B Grade .1Mm Outside

Jeep Piston Part Number: 68210589AA

$109.16 MSRP: $164.00You Save: $54.84 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Piston - Engine; Piston Engine C Grade .1Mm Outside

Jeep Piston Part Number: 68067508AA

Product Specifications- Replaces: 4778860AB, 4778856AB, 4778858AB

Jeep Piston Part Number: 4778871AB

Product Specifications- Other Name: Piston - B - Size; Piston Pin And Rod B - Size

- Replaced by: 68067509AA

Jeep Piston Part Number: 68067510AA

Product Specifications- Replaces: 4778872AD, 4778876AB, 4778876AD, 4778876, 4778874AD, 4778876AC

Jeep Piston Part Number: 68013995AB

Product Specifications- Replaces: 68013995AA, 5179424AB, 68034932AA, 5179424AC, 5179424AA

| Page 1 of 3 |Next >

1-20 of 60 Results

Jeep Piston

OEM parts sourced directly from Jeep deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Jeep Piston for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

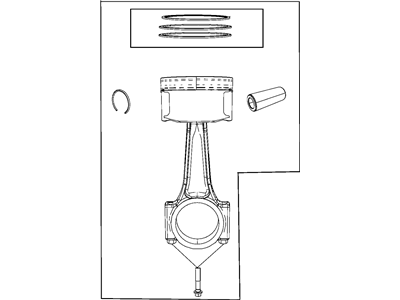

Jeep Piston is a device that transforms the explosive blasts of a cylinder into useful crankshaft push to pull the real world. Jeep has constructed an image based on metal that swears cliffs, mud holes, and desert heat. Each cabin is open to air and sun, thus drivers experience landscape rather than displays. Jeep couples that rough it outdoors are availed with Selec-Terrain, a dial that can transition from snow to sand in a jiffy. Voice recognition can alternate music, maps, and weather without having to jerk eyes out of rocky ruts. Jeep also goes with over-the-air updates that optimize traction logic while your boots are drying. Social trips to far ridges unite owners more closely than any promise at the showroom. The mundane commuting is transformed into a mini-expedition in Jeep rides, and curiosity keeps day-to-day life wired. Trail-tuned suspensions stretch and absorb drops and fall square without having to rattle the fillings around. Piston walls are able to resist the scorching expansion gas, slide in the micron-thin oil film, and push the crank along a forged rod at thousands of explosions per minute. Piston alloy comes in rough-trunk frameworks able to withstand heavy loads on the sides to featherweight race slugs able to slice reciprocating mass and allow revolutions to fly. The shape of the Piston crown is applied to shape the flame front to squeeze more push out of each drop and reduce fuel bills. Piston skirt coating dampens slaps and eliminates vibration so engines are hushed decades after years of trail abuse.

Jeep Piston Parts and Q&A

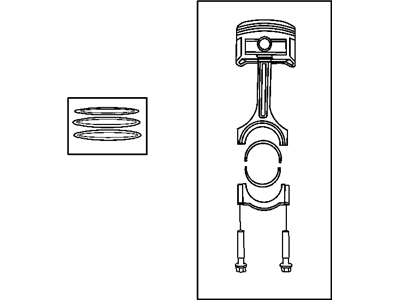

- Q: How to inspect piston/connecting rod assemblies on Jeep Cherokee?A:Before inspection, clean piston/rod assemblies and remove old piston rings. Use tools to remove carbon deposits without damaging the pistons. Clean assemblies with solvent and dry with compressed air. If pistons and cylinder walls are undamaged, new pistons may not be needed, but always use new rings. You can inspect each piston for cracks, scoring, and signs of overheating or coolant leakage. Check for excessive wear and if needed, have pistons, rods, and pins resized at a machine shop. Replace old bearing inserts and tighten rod caps.

- Q: What steps should be taken before installing the piston and connecting rod assemblies on Jeep Wrangler?A:Before the piston and connecting rod assemblies are placed in position, this should be done after cleaning the cylinder walls and after chamfering the top edge of each cylinder and with the crankshaft in position. Depress the cap of the No.1 connecting rod and pull it off, ensuring that the marks made during removal of the cap are recorded and then wipe the bearing surfaces with a lint free cloth. Remove the old dust cover and clean the back side of the new upper bearing insert; insert it into the connecting rod so that the tab does not require hammering into the recess. This must be done for the lower bearing insert touching the rod cap, with great emphasis on the cleanliness and absence of oil on the contacting surfaces. Align the piston ring gaps around the piston, slide a hose over each conducting rod cap screw, put some clean engine oil on the piston and on the rings, and then engage a piston ring compressor such that the piston skirt stands proud. Turn the crankshaft until the first connecting rod journal is at BDC and lubricate the cylinder walls of any new cylinder being prepared for assembly. Slide the piston/connecting rod assembly into the cylinder bore with the arrow on the piston pointing towards the front of the engine; the ring compressor will fit to the block. Insert the piston with a slight force into the cylinder while aligning the connecting rod on a term of crank shaft journal in case there is any resistance. Upon the completion of installation, Plastigage should be used in determining the oil clearance of the connecting rod bearing and the width crashed should be compared to the scale on the envelope. If the clearance is wrong, look for any dirt traces during the measurement process and compare the journal diameter. Removal of Plastigage must be gentle and any leftover material should be removed; subsequently a thin layer of moly-base grease or engine assembly lube must be applied to the bearing faces and finally connect the connecting rod and cap with nuts or bolts to the recommended torque. Perform this procedure for the other pistons and connecting rods bearing inserts and interior of connecting rods must be clean and the correct piston/rod assembly must fit the relevant cylinder cylinder walls and bearing faces must be lubricated when necessary. After all assemblies are installed, rotate the crankshaft and check for binding and measure the connecting rod end play and with reference to standard check if it is correct. It maybe required if new rods or a crankshaft has been installed.