JeepParts

My Garage

My Account

Cart

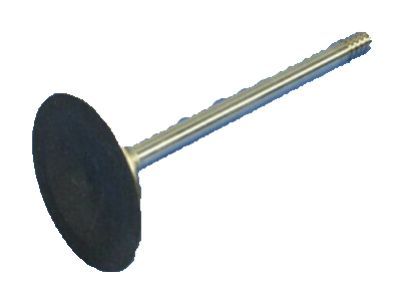

OEM Chrysler Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Intake Valves found

Chrysler Intake Valve Part Number: 68453301AA

$17.61 MSRP: $26.10You Save: $8.49 (33%)Product Specifications- Other Name: Valve - Engine Intake; Valves; Valve Engine Intake

- Replaces: 5047446AA

Chrysler Intake Valve Part Number: 5184127AC

$24.74 MSRP: $36.70You Save: $11.96 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valve Intake Standard

Chrysler Intake Valve Part Number: 53022087AC

$25.03 MSRP: $37.15You Save: $12.12 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valve Intake Standard

- Replaces: 53022087AA, 53022087AB

Chrysler Intake Valve Part Number: 53020747AB

$46.65 MSRP: $94.55You Save: $47.90 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valves; Valve Intake Standard 3 Per Cylinder Head; Valve Intake Standard

Chrysler Intake Valve Part Number: 5038331AB

$93.10 MSRP: $141.00You Save: $47.90 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valve Intake Standard Quantity Is Per Cylinder Head; Valve Intake Standard

Chrysler Intake Valve Part Number: 5047917AA

$13.62 MSRP: $20.30You Save: $6.68 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valve Intake Standard

Chrysler Intake Valve Part Number: 4781025AA

$37.05 MSRP: $54.30You Save: $17.25 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valves; Valve Intake Standard

Chrysler Intake Valve Part Number: 4663836

$26.34 MSRP: $38.35You Save: $12.01 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valve Intake Standard

Chrysler Intake Valve Part Number: 4884691AA

$26.23 MSRP: $33.60You Save: $7.37 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valves; Valve Intake Standard

- Replaces: 4667969AB

Chrysler Intake Valve Part Number: 4694222

$4.58 MSRP: $5.80You Save: $1.22 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valve Intake Standard

Chrysler Intake Valve Part Number: 4448052

$3.50 MSRP: $4.43You Save: $0.93 (21%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valves; Valve, Intake Standard; Valve Intake Standard; Valve, Intake

Chrysler Intake Valve Part Number: 4298137

$14.79 MSRP: $17.00You Save: $2.21 (13%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake Standard; Valves; Intake Standard W/Ede Carbureted or Edj High-Performance Engine.

Chrysler Intake Valve Part Number: 53021990AA

Product Specifications- Other Name: Valve - Intake; Valves; Valve Intake Standard

Chrysler Intake Valve Part Number: 53021550AA

Product Specifications- Other Name: Valve - Intake; Valve Intake Standard

Chrysler Intake Valve Part Number: 4667969

Product Specifications- Other Name: Valve; Valves; Valve, Intake - Standard; Valve Intake Standard

Chrysler Valves Part Number: 5097170AB

Product Specifications- Other Name: Valve - Intake; Intake Valve; Valve Intake Standard

Chrysler Intake Valve Part Number: MD088811

Product Specifications- Other Name: Valve; Valves; Valve, Intake, Single Cam; Valve Intake Standard; Valve, Intake; Valve, Inlet

Chrysler Intake Valve Part Number: 4323244

Product Specifications- Other Name: Valve; Valves; Intake Standard W/Ede Carbureted or Edj High-Performance Engine.

Chrysler Intake Valve Part Number: 4663345

Product Specifications- Other Name: Valve Intake; Valve Intake Standard; Valve, Cylinder Head

Chrysler Intake Valve Part Number: MD301193

Product Specifications- Other Name: Valve - Intake; Valve Seals; Valves; Valve Intake Standard; Valve

- Replaces: MD159502

| Page 1 of 2 |Next >

1-20 of 24 Results

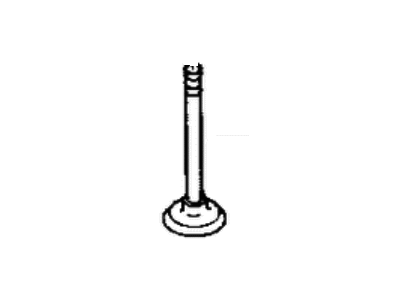

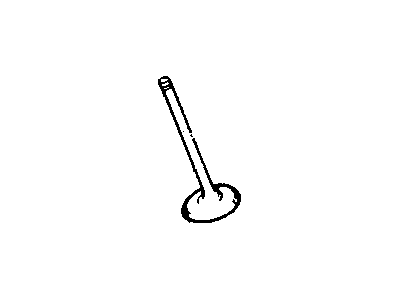

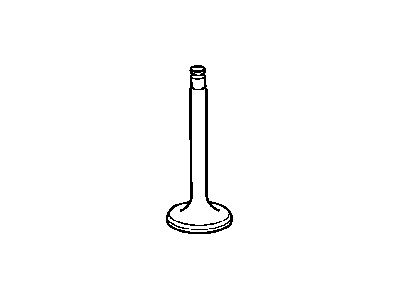

Chrysler Intake Valve

OEM parts sourced directly from Chrysler deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Chrysler Intake Valve for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

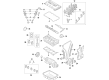

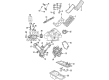

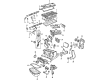

Chrysler Intake Valve opens at just the right time to supply perfect air to charge the engine. When Chrysler began in 1925, it had good-quality solid machines that reduced harmful vibration by Floating Power engine mounts to allow its families to roam without the rattles of early motoring. Chrysler pursued less bumpy rides and more graphic appearances and dumped the flamboyant Airflow design to direct wind over the engine section and silence the cabin as it increased speed. Another first that Chrysler introduced was the original practical minivan, which matched sliding-door access and flat cargo floors to allow weekend stuff and children to crash in without the gymnastics. Chrysler stretched interior space and ride comfort many times over and supported it through downright pricing that made upgrades painless and ensured that the utility aspect of the brand remained front and center to the everyday consumer. Intake Valve timing controls the swallow of the air-fuel blend, opening wide when the piston drops and closing speedily when it rises, which ensures that combustion remains lively and the torque is made readily available on order. The Intake Valve strength is important since the component is slamming open and closed many thousand times a minute, so alloy materials and stems that resist heat defend against warping that will steal power and increase emissions. Intake Valve reliability helps drivers avoid misfires, icy idle, and shocking repair bills as it stops leaks that cause an irritating compression. Even fuel economy is boosted by Intake Valve health as it allows the engine to breathe the right amount of air and not excessively, wasting petrol and reducing tailpipe emissions.

Chrysler Intake Valve Parts and Q&A

- Q: How Are Exhaust Valves and Intake Valves Machined and What Factors Should Be Considered on Chrysler Town & Country?A:The intake and exhaust valves and seats are finished to set angles. After complete the valve refacing process, examine what remains on the margin. When refacing valve seats, avoid scraping metal from along the head gasket while fixing the valve seat only. Making sure to pick the right size of valve guide pilots guarantees the plate surface is true. With a dial indicator, check that the runout at the valve seat does not go higher than 0.051 mm (0.002 in.) To check if the valve is making contact, use Prussian blue on the valve seat; if the blue stays on the valve face as a dot, everything is fine. For a transfer to the top, lower the seat with a 15-degree stone; for one to the bottom edge, fix the valve seat with a 65-degree stone. Should the angle or width be wrong, the cylinder head must be changed; if they remain correct, the worn or burned valve seats can be repaired. The intake and exhaust seat width should be between 1.50 and 2.00 mm (0.059 - 0.078 in.). Once valve seats or faces are ground, put the valve in the cylinder head and check distance from the tip of the valve to the spring seat. If the valve tip needs adjustment, keep grinding it until it is perfect and then resurface the tip chamfer, if needed, so the seal is not ruined. Lastly, check the spring's installed height after refacing; if the height is too much, add a 0.794 mm (0.0312 in.) spacer to the head counterbore to reduce the spring's height to the correct level.

- Q: How to Remove and Replace Exhaust Valve and Intake Valves on Chrysler Crossfire?A:You should begin by taking off the cylinder head and setting it on a workbench when you want to remove and replace a valve. After that, with C-3422-CF Valve Spring Compressor, compress the valve spring and take out the collets. Once you have removed the valve spring compressor, pull the valve retainer and valve spring together with the spacer out. Remove the valve stem seal with Special Tool 9106 Valve Assembly Tool Case. After that, get rid of the valve from the cylinder head and check it for damage or scratches on both the face and stem. Replace the valve if anything seems wrong.