JeepParts

My Garage

My Account

Cart

OEM Jeep Liberty Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Piston Ring Sets found

Jeep Liberty Piston Rings Part Number: 5073524AA

$3.65 MSRP: $252.00You Save: $248.35 (99%)Ships in 1-2 Business Days

Jeep Liberty Piston Rings Part Number: 5012364AE

Jeep Liberty Piston Rings Part Number: 4897024AA

Jeep Liberty Piston Rings Part Number: 5142543AB

Jeep Liberty Piston Ring Set

Choose OEM Piston Ring Set that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Jeep Liberty matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Liberty parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

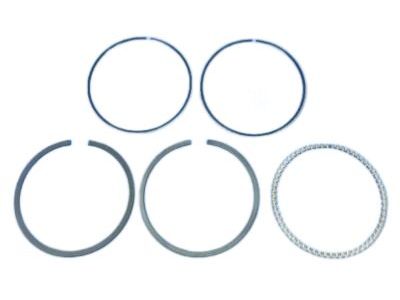

The Piston Ring Set of Jeep Liberty models exhibits known reliability and performance standards that advance engine efficiency and service life expectancy. This Piston Ring Set was explicitly developed for Jeep Liberty models from 2002 to 2012 to generate ideal combustion chamber sealing which enables proper fuel-air mixture combustion alongside prevention of gas leakage and control of engine oil. Different styles of piston rings exist in Jeep Liberty but modern designs lean towards thin configurations which decrease friction and boost ring sealing performance. The Jeep Liberty's overall operational safety and efficiency depends strongly on this component since it affects its engine's working ability. Ductile iron alongside particular coatings in the Piston Ring Set enables resistance to heat and ensures durability that separates this product from others in the automotive market. The Piston Ring Set demonstrates versatility because it operates with all Jeep Liberty models from KJ to KK generations. The brand model Piston Ring Set increases vehicle safety on the road through improved oil control functionality and reduced engine wear. As an essential component designed for the car the Piston Ring Set continues to serve the automaker enthusiasts who need to preserve their vehicle reliability while enhancing efficiency.

Jeep Liberty Piston Ring Set Parts and Q&A

- Q: How to Check Clearances and Install a Piston Ring Set on Jeep Liberty?A:Always wipe the cylinder bore clean and insert the ring so that the gap measurement is made with the ring placed about 12 mm (0.50 inch) above the cylinder's bottom. Slide the ring down toward the crankshaft base with a Piston, then see if it's squared by checking it with a feeler gauge. Replace any ring that doesn't match the required gap. Verify that inside the piston ring grooves are clear and free from any scratches, cuttings or damaging burrs; first place a feeler gauge with only a thin gap between the piston ring surfaces, measure the space and replace any ring that does not meet specification. Spin the ring on the piston and notice if it turns freely in the groove or if it gets stuck. Since the No. 1 and No. 2 piston rings are built differently, install the No. 2 ring so the manufacturer's Dot mark is facing upward on your piston. The order for installing piston rings is oil ring expander, top oil ring rail, lower oil ring rail, the intermediate No. 2 ring, then the upper No. 1 ring. First install the oil ring expander, then put one end of the upper side rail in the groove between it and the expander, press down and do the same for the lower side rail. To fit the intermediate piston ring, place the receiver and use the piston ring installer. Position the piston ring gaps so that the expander ring gap is not closer than 45° to either side rail gap and not directly on the piston pin or in the direction toward the engine thrust.