JeepParts

My Garage

My Account

Cart

OEM Jeep Liberty Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Fuel Rails found

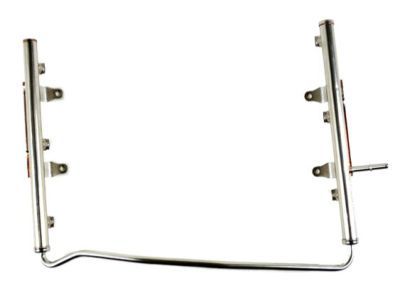

Jeep Liberty Fuel Rail Part Number: 53031102AB

$512.72 MSRP: $777.00You Save: $264.28 (35%)

Jeep Liberty Fuel Rail Part Number: 5135582AB

Jeep Liberty Fuel Rail Part Number: RL000898AA

Jeep Liberty Fuel Rail Part Number: 5072484AC

Jeep Liberty Fuel Rail

Choose OEM Fuel Rail that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Fuel Rail follows strict manufacturing steps to lock in quality and fit. If your Jeep Liberty matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Liberty parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Jeep Liberty Fuel Rail Parts and Q&A

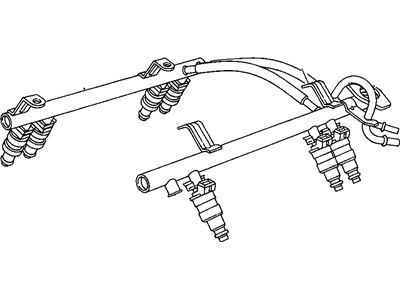

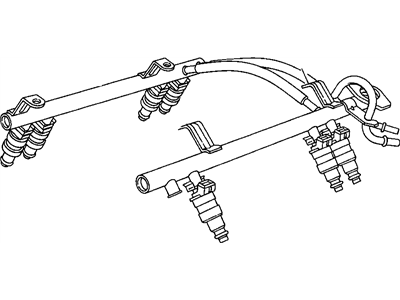

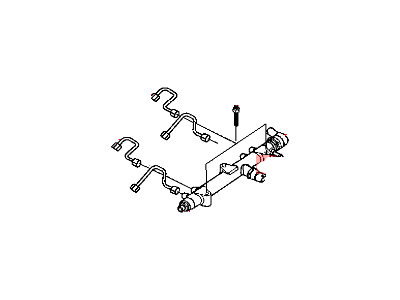

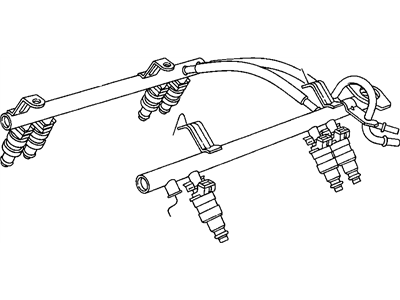

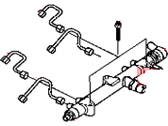

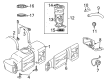

- Q: How to Remove the Fuel Rail on a 3.7L Engine on Jeep Liberty?A:Before attempting to remove the fuel rail, ensure first that the pressure from the fuel system is released, because it is still there even with the engine turned off. The entire assembly of left and right fuel rails must be changed together and do not separate the rails at the tube connector, as there are no clamps there; don't use any clamp on the tube either. Take out the fuel tank filler tube cap, then perform the step for releasing pressure from the fuel system. First, disconnect the negative on the battery, then get rid of the Air Duct and air box at the Throttle Body. You should use a special tool to unhook the latch clip and link at the fuel rail on the fuel line. Take out appropriate vacuum or vapor lines at the throttle body and with a red slider, push away the tabs connecting each of the six Fuel Injectors and remove them. Each injector is identified on the wiring harness by a tag for simple location. Take out the throttle body sensors by disconnecting their electrical cables, then remove the six Ignition Coils. After that, take out the four bolts that connect the fuel rails to the engine. On the left air rail, gently rock and move it until the fuel injectors fit over the machined holes in the cylinder head and then repeat on the right air rail until all injectors have cleared. Remove the rail attached to the injectors as the last step from the engine. When it is time to detach fuel injectors, use the proper steps for their removal.

- Q: How to Properly Service and Install a Fuel Rail on Jeep Liberty?A:Releasing the pressure in the fuel system is necessary before you work on the fuel rail, because the pressure is always high even when the engine is not running. Again, the connector tube (10) is not held by a clamp and must stay together with the left and right rail halves because we won't be assembling them as separate items. Make sure the fuel tube stays straight and isn't twisted as you take out the fuel rail assembly. Take off the fuel tank filler tube cap to begin and do the Fuel System Pressure Release Procedure afterward. Cut off the second Battery Cable, disconnect the air duct and air box from the Throttle Body and remove the clip and fuel line at the fuel rail using a suitable tool. Take out any essential vacuum lines and unplug the electrical connectors at all six Fuel Injectors, pulling the red slider apart as you depress the tab to pull them off. Separate the electrical plugs at the throttle body sensors, take out the six Ignition Coils and unbolt the four bolts that hold the fuel rails. Move the fuel rail slowly side to side on the left until the injectors clear the holes in the cylinder head and do the same on the right side until you are finished. Take off the fuel rail, along with the injectors, from the engine. If you have to put in new injectors, first clean the bores of the Intake Manifold and then oil the O-ring on each injector using just a small amount of oil to help with installation. Set the fuel rail/fuel injector assembly into the cylinder head above the machined openings, taking care not to tear the O-rings. Firmly push down on both ends of the fuel rail so the injectors sit properly on the cylinder head, bolt the rail down with the four bolts and tighten them by 11 N.m (100 in. lbs). Screw the six ignition coils back in and join the electrical connectors from the throttle body and fuel injectors to make sure they are not loose. For the vacuum lines, the fuel line latch clip and the fuel line going to the fuel rail, join them firmly back to their points of connection. After that, fix the air box and air duct back into place, connect the battery and start the engine to test for any leaks.