JeepParts

My Garage

My Account

Cart

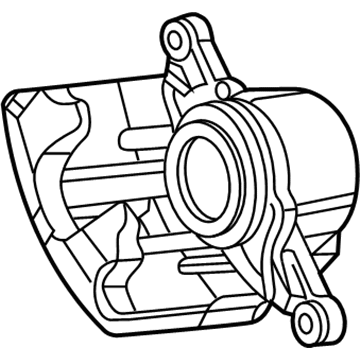

OEM Chrysler Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

112 Brake Calipers found

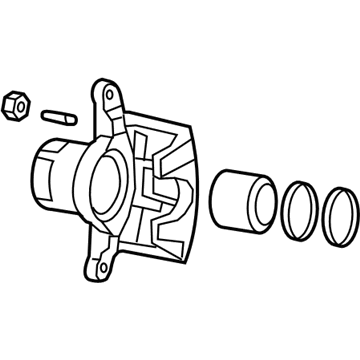

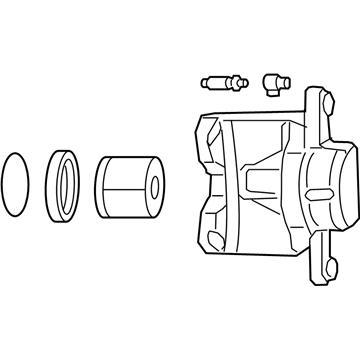

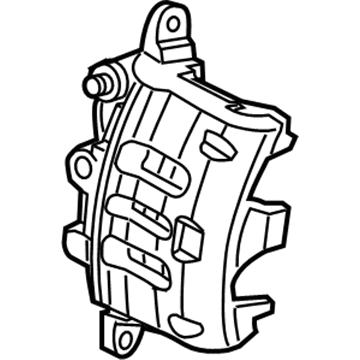

Chrysler Caliper, Front Driver Side Part Number: 5191239AA

$113.04 MSRP: $171.00You Save: $57.96 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper Assembly Disc Brake Front; Brake Caliper

- Position: Front Driver Side

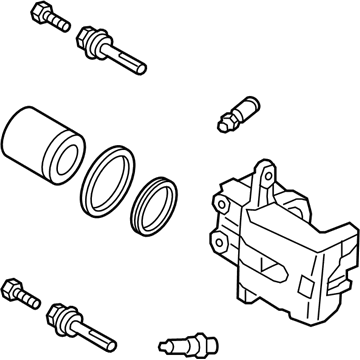

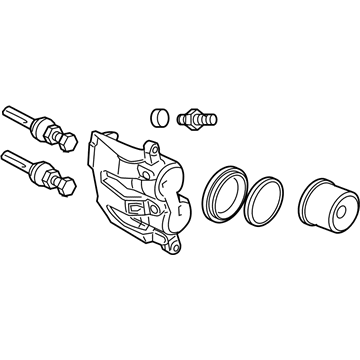

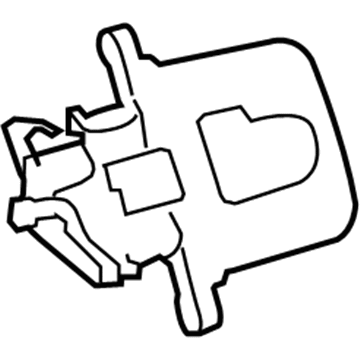

Chrysler Caliper, Black, Rear Driver Side Part Number: 68144271AA

$625.85 MSRP: $948.00You Save: $322.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Caliper Assembly Disc Brake Rear; Brake Caliper

- Position: Rear Driver Side

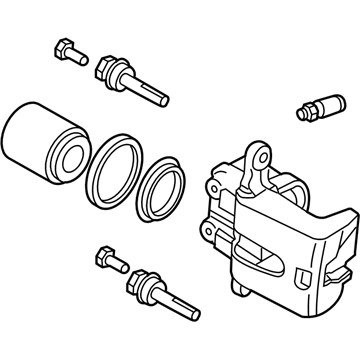

Chrysler Caliper, Rear Passenger Side Part Number: 68548608AA

$134.43 MSRP: $199.00You Save: $64.57 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Brake Caliper

- Position: Rear Passenger Side

- Replaces: 5142564AA, 5142564AB

Chrysler Caliper Assembly, Front Passenger Side Part Number: 68548604AA

$168.42 MSRP: $250.00You Save: $81.58 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left, Front Right; Brake Caliper; Caliper

- Position: Front Passenger Side

- Replaces: 5137670AB, 5137670AA

Chrysler Caliper, Front Driver Side Part Number: 68157611AB

$201.28 MSRP: $299.00You Save: $97.72 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left, Front Right; Brake Caliper

- Position: Front Driver Side

- Replaces: 5143358AD, 68037147AA, 5143358AF, 5143358AE, 68002702AA, 68157611AA

Chrysler Caliper, Front Driver Side Part Number: 68157610AB

$206.94 MSRP: $308.00You Save: $101.06 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left, Front Right; Brake Caliper

- Position: Front Driver Side

- Replaces: 68002703AA, 5143348AF, 5143348AD, 5143348AE, 68037144AA, 68157610AA

Chrysler Caliper, Rear Driver Side Part Number: 68548609AA

$135.56 MSRP: $200.00You Save: $64.44 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Brake Caliper

- Position: Rear Driver Side

- Replaces: 5142565AB, 5142565AA

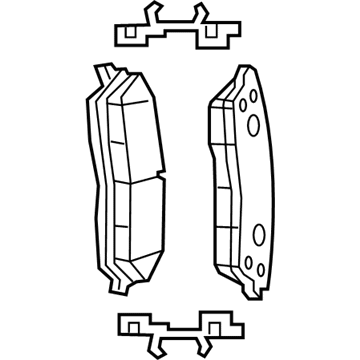

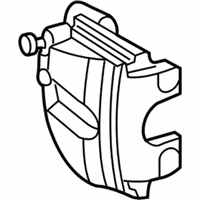

Chrysler Brake Pads, Front Part Number: 68144213AC

$334.24 MSRP: $492.00You Save: $157.76 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pad Kit - Front Disc Brake; Front Pads; Caliper

- Position: Front

- Replaces: 68144213AB, 68144213AA

Chrysler Caliper, Rear Passenger Side Part Number: 5179880AE

$154.61 MSRP: $230.00You Save: $75.39 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Brake Caliper

- Position: Rear Passenger Side

- Replaces: 5080560AA, 5179880AC, 5179880AB, 5179880AA, 5179880AD

Chrysler Caliper, Front Driver Side Part Number: 68144161AA

$178.30 MSRP: $262.00You Save: $83.70 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper Assembly Disc Brake Front; Brake Caliper

- Position: Front Driver Side

- Replaces: 68144161AB

Chrysler Caliper, Rear Driver Side Part Number: 68144207AC

$120.84 MSRP: $180.00You Save: $59.16 (33%)Product Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Caliper Assembly Disc Brake Rear; Brake Caliper

- Position: Rear Driver Side

- Replaces: 68144207AA, 68144207AB

Chrysler Caliper Part Number: 68144206AC

$123.07 MSRP: $184.00You Save: $60.93 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Brake Caliper; Caliper Assembly Disc Brake Rear

- Replaces: 68144206AA, 68144206AB

Chrysler Caliper Clip, Rear Driver Side Part Number: 5179881AE

$113.35 MSRP: $169.00You Save: $55.65 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Brake Caliper Repair Kit; Disc Brake Hardware Kit; Brake Caliper; Caliper

- Position: Rear Driver Side

- Replaces: 5179881AA, 5179881AC, 5179881AB, 5179881AD

Chrysler Caliper, Rear Passenger Side Part Number: 68548610AA

$115.17 MSRP: $169.00You Save: $53.83 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Brake Caliper

- Position: Rear Passenger Side

- Replaces: 5142562AA, 5142562AB

Chrysler Caliper, Rear Passenger Side Part Number: 68318172AB

$285.51 MSRP: $430.00You Save: $144.49 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Caliper Assembly Disc Brake Rear; Brake Caliper

- Position: Rear Passenger Side

- Replaces: 68318172AA

Chrysler Caliper Assembly, Front Driver Side Part Number: 68548603AA

$132.16 MSRP: $194.00You Save: $61.84 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Brake Caliper; Caliper

- Position: Front Driver Side

- Replaces: 5140824AA, 5142557AA, 5142557AB

Chrysler Caliper, Rear Driver Side Part Number: 68029848AE

$152.24 MSRP: $226.00You Save: $73.76 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left, Rear Right; Brake Caliper

- Position: Rear Driver Side

- Replaces: 68029848AB, 68029848AA, 68029848AD, 68029848AC

Chrysler Caliper, Rear Driver Side Part Number: 68029849AE

$152.24 MSRP: $226.00You Save: $73.76 (33%)Product Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left, Rear Right; Brake Caliper

- Position: Rear Driver Side

- Replaces: 68029849AA, 68029849AB, 68029849AD, 68029849AC

Chrysler Caliper, Front Driver Side Part Number: 5072551AA

Product Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper Disc Brake; Brake Caliper

- Position: Front Driver Side

Chrysler Caliper, Front Passenger Side Part Number: 4605A019

Product Specifications- Other Name: Caliper - Front Brake; Disc Brake Caliper, Front Left, Front Right; Caliper Kit Front Brake

- Position: Front Passenger Side

- Replaces: MN102870

| Page 1 of 6 |Next >

1-20 of 112 Results

Chrysler Brake Caliper

OEM parts sourced directly from Chrysler deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Chrysler Brake Caliper for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

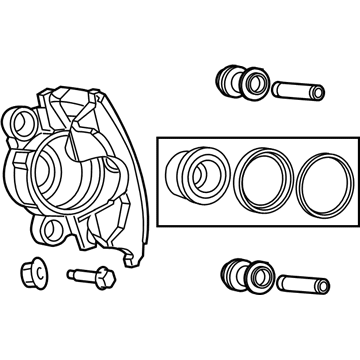

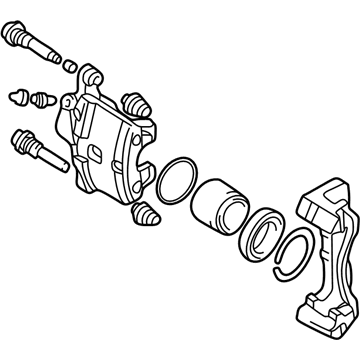

Chrysler Brake Caliper transformed hydraulic pressure into acute stopping force having a reliable balanced grip. On the foundations of solid steel, smooth running motors, and straightforward pricing, Chrysler developed a name on top and Floating Power mounts slashed engine rumble and bold Airflow lines pushed wind away so the riders could enjoy a quieter cooler inside without having to compromise on purchase. Next came Chrysler who appalled the suburbs with the first true minivan, sliding doors and flat floors meaning that on weekends or school pickups, there would be no pain at the wallet or fun sucked out of an open road. Chrysler continues to polish ride, seating, and cargo gimmicks annually, seeking everyday practicality instead of empty flash, thus making trips on the road easy and errands easy. Brake Caliper is the one that transfers the fluid contained in a master cylinder to clamp force through the pistons moving in a cast-iron shell forcing the pads close to the rotors to cut off speed in a flick of a finger. Brake Caliper is either fixed with pistons on the right and left sides to provide balanced bite or floating which slide on a pin but must have clean slides to allow gripping. In Chrysler, supporting rotor sizes to weight and tire specifications are mated to each layout to make pedal feel predictable in traffic. Brake Caliper malfunction indicates that one pad will be worn out more quickly, and therefore replacement of pins and bleeding lines will restore the pedal to life. Brake Caliper by installing larger bore and bright finishes reduce the cutting yardage and provide swagger to the driveway at low cost.

Chrysler Brake Caliper Parts and Q&A

- Q: How to Remove and Replace a Brake Caliper on Chrysler 300?A:On a rear-wheel-drive vehicle, look at the brake pads and replace them if they are worn. Indeed, gently push the caliper pistons back into the caliper with your hand or a C-clamp, keeping a wood block on the piston to avoid eating any imprecaution. Be sure not to tear the boots on the caliper guide pins when you attach the caliper to the disc brake adapter. Make sure the caliper guide pins are inserted into the caliper adapter which will clear the caliper bosses and then push the caliper onto the brake pads and onto the adapter. Always check that the guide pin bolts are threaded correctly before putting the caliper in place. Place the caliper on top of the mounting holes, secure the guide pin bolts using a torque wrench at 60 Nm (44 ft. lbs.) and hold the guide pins so they don't turn as you tighten. After that, put in the banjo bolt joining the hose to the caliper, placing new washers on each side of the hose fitting and tighten it to a torque of 50 Nm (37 ft. lbs.). Install and fasten the wheel and tire assembly to the vehicle, screwing the mounting nuts to 150 Nm (110 ft. lbs.) or 190 Nm (140 ft. lbs.) for cops. Drop the vehicle, take out the post holding tool and link the battery negative cable to the post. Performing this part of the experiment well is very important. Don't forget to bleed the base brake hydraulic system and, when done, take the vehicle on a road test including a few stops where the brakes, once stationary, allow the brake lining to bed into the drums.

- Q: How to Remove and Replace a Front Disc Brake Caliper on Chrysler Crossfire?A:Place the brake pads onto the disc caliper, both inside and outside, the moment you take it off. Smear the slide pins and slide bushings with silicone grease and after that, place the caliper on the mounting bracket. After attaching the slide pins, secure each pin with 25 Nm (18 ft. lbs.). Link the brake pad wear indicator to the caliper and tighten the bolt to 8 Nm (6 ft. lbs.) and then join the indicator to the brake pad. Fit the first end of the caliper support spring into the top caliper, under the bracket and install the other end into the caliper hole at the bottom. Keep the spring in the caliper hole with your thumb as you use the screwdriver to pull the end out and down under the bracket. Straighten the brake hose and smooth it out before securely holding the fitting, after which you can connect it to the caliper. The brake system can be filled and bled manually or with a help from a press. Put the wheel and tire on the vehicle and do not start moving it until you can confidently brake. Raise the vehicle back up and repeatedly pump the brake pedal until the caliper pistons and brake pads settle. If the brake fluid reservoir needs it, put in new brake fluid and make sure there are no leaks.