JeepParts

My Garage

My Account

Cart

OEM Dodge Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

287 Axle Shafts found

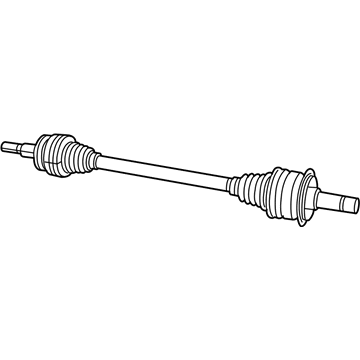

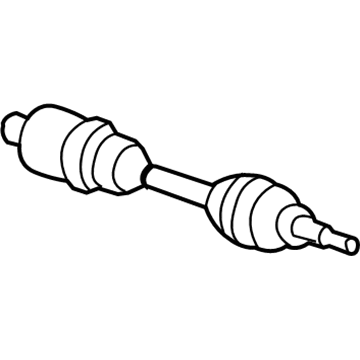

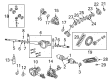

Dodge Axle Assembly, Rear Driver Side Part Number: 53010749AA

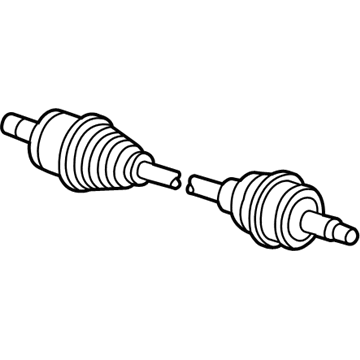

$538.06 MSRP: $786.00You Save: $247.94 (32%)Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear Left; Axle Shaft; Shaft Axle Half

- Position: Rear Driver Side

- Replaces: 53010671AB, 53010671AC, 53010671AD

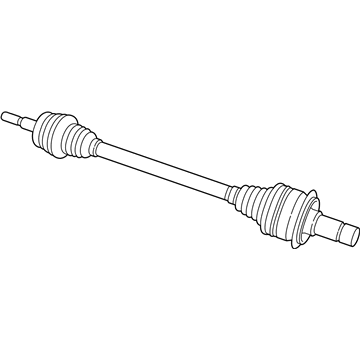

Dodge Axle Assembly Part Number: R4578600AA

$259.37 MSRP: $305.00You Save: $45.63 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Axle Half; Axle Shaft; Shaft Axle Half

Dodge Axle Assembly Part Number: R4578601AA

$259.37 MSRP: $305.00You Save: $45.63 (15%)Product Specifications- Other Name: Shaft - Axle Half; Axle Shaft; Shaft Axle Half

Dodge Axle Assembly, Rear Part Number: 68258859AB

$589.58 MSRP: $861.00You Save: $271.42 (32%)Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear; Axle Shaft; Shaft Axle Half

- Position: Rear

- Replaces: 68258859AA

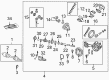

Dodge Axle Assembly, Rear Passenger Side Part Number: 5180492AC

$645.27 MSRP: $971.00You Save: $325.73 (34%)Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear Right; Axle Shaft; Shaft Axle Half

- Position: Rear Passenger Side

- Replaces: 5180492AB

Dodge Axle Assembly, Rear Driver Side Part Number: 52123971AD

$509.43 MSRP: $745.00You Save: $235.57 (32%)Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear Left; Axle Shaft; Shaft Axle Half

- Position: Rear Driver Side

- Replaces: 52123971AB, 52123971AC

Dodge Axle Assembly, Rear Part Number: 52123952AD

$369.02 MSRP: $559.00You Save: $189.98 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear; Axle Shaft; Shaft Axle Half

- Position: Rear

- Replaces: 52123952AA, 52123952AB, 52123952AC

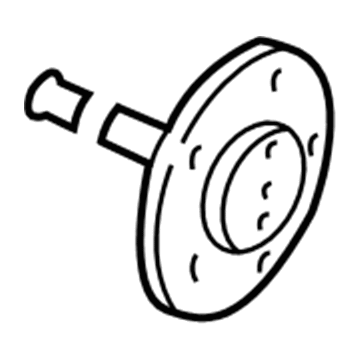

Dodge Axle Shaft, Rear Passenger Side Part Number: 4726090AD

$416.53 MSRP: $632.00You Save: $215.47 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear Right; Constant Velocity Axle; Axle Assembly; Shaft Axle Half; CV Axle Assembly

- Position: Rear Passenger Side

- Replaces: 4726090AC, 4726090AB

Dodge Axle Shaft, Rear Part Number: 52114720AB

$561.34 MSRP: $853.00You Save: $291.66 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft - Axle Rear; Drive Axle Shaft, Rear; Axle Shafts; Shaft Axle Rear

- Position: Rear

- Replaces: 52114720AA

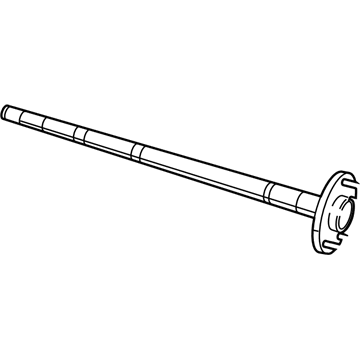

Dodge Intermediate Shaft, Front Passenger Side Part Number: 52114636AB

$142.76 MSRP: $212.00You Save: $69.24 (33%)Product Specifications- Other Name: Shaft - Axle Intermediate; Drive Axle Shaft, Front Right; Axle Shafts; Intermed Shaft; Shaft Axle Intermediate; Axle Shaft

- Position: Front Passenger Side

- Replaces: 52114636AA, 52114389AA

Dodge Axle Assembly Part Number: R5170822AA

$78.09 MSRP: $90.15You Save: $12.06 (14%)Product Specifications- Other Name: Shaft - Axle Half; Axle Shaft; Shaft Axle Half

Dodge Axle Shaft, Front Passenger Side Part Number: 5170822AA

Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Front, Front Left, Front Right; Constant Velocity Axle; Axle Assembly; Shaft Axle Half; CV Axle Assembly

- Position: Front Passenger Side

- Replaces: 52114556AA, 5072389AB, 68046657AA, 68002450AB

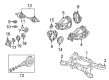

Dodge Axle Assembly, Rear Driver Side Part Number: 4578733AE

$732.71 MSRP: $1065.00You Save: $332.29 (32%)Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear Left; Axle Shaft; Shaft Axle Half

- Position: Rear Driver Side

- Replaces: 4578733AC, 68194755AA, 4578733AB

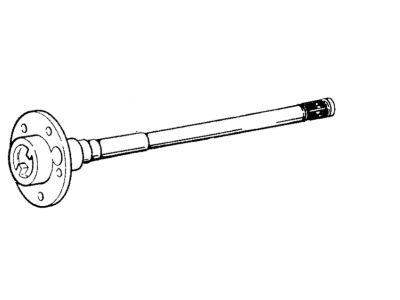

Dodge Axle Shaft, Rear Part Number: 4506115

Product Specifications- Other Name: Shaft Rear Axle Drive; Axle Shafts; Shaft, Rear Axle Drive; Shaft, Drive

- Position: Rear

Dodge Axle Shaft Part Number: 4746620

Product Specifications- Other Name: Shaft - Axle; Axle Shafts; Shaft, Rear Axle Drive; Shaft Axle

Dodge Axle Shaft Part Number: 4746990

Product Specifications- Other Name: Shaft - Axle; Axle Shafts; Shaft, Rear Axle Drive; Shaft Axle

Dodge Axle Assembly, Front Passenger Side Part Number: MR410042

Product Specifications- Other Name: Shaft - Front Axle; CV Axle Assembly, Front Right; Constant Velocity Axle; Axle Shaft; Shaft Front Axle; CV Axle Assembly

- Position: Front Passenger Side

Dodge Axle Shaft, Rear Passenger Side Part Number: 52070498AC

Product Specifications- Other Name: Shaft - Axle Rear; Drive Axle Shaft, Rear Right; Axle Shafts; Shaft Axle Rear

- Position: Rear Passenger Side

- Replaces: 52070498AB

Dodge Axle Assembly, Rear Part Number: 68035016AB

Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear; Constant Velocity Axle; Axle Shaft; Shaft Axle Half; CV Axle Assembly

- Position: Rear

Dodge Axle Assembly, Rear Part Number: 68035017AB

Product Specifications- Other Name: Shaft - Axle Half; CV Axle Assembly, Rear; Constant Velocity Axle; Axle Shaft; Shaft Axle Half; CV Axle Assembly

- Position: Rear

| Page 1 of 15 |Next >

1-20 of 287 Results

Dodge Axle Shaft

OEM parts sourced directly from Dodge deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Dodge Axle Shaft for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Dodge Axle Shaft utilizes the raw torque directly to the wheels designed to make all stomps immediate. In 1914, Dodge cut its image in rolling out the first all steel body that sneered at poor rivals. The brand continued to shake with screeching HEMI engines which transformed shopping trips into drag racers. Dodge went to extremes once again as the Viper program demonstrated that showroom vehicles could inhale the adrenaline of the racetrack. The new Dodge Fratzonic Chambered Exhaust demonstrates that the company will not allow electric silence to murder muscle attitude, with a 600 watt growl that it is adjusting to all the drive modes. There is a Stealth Mode when you are in a quiet environment though punch Sport or Drag and the Dodge speakers scream defiance. The drivers are confident since the chassis, body panels, and power systems are all no nonsense of the same mental durability. Attitude of the muscle makes all badges, hauling lumber, drifting the corner, or flying past the quarter mile marker. Axle Shaft connections with wheel, weight, torque, and loads. The shaft also allows wheels on the left and right to turn at different speeds which imply that grip remains firm on slick corners. Axle Shaft is put under shear due to payloads, potholes, throttle bursts; when the tube becomes warped or scored, noise and shudder is a warning of greater damage. Leak, play, or knock checks keep the assembly in line and cushion the adjacent hubs. The Axle Shaft swaps are installed with splined ends and covered bearings, cutting down the time and putting the vehicle on the road quickly. A healthy Axle Shaft transforms pedal pressure into movement, nothing dramatic, it is simply thrust.

Dodge Axle Shaft Parts and Q&A

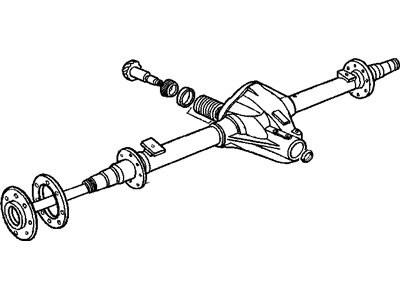

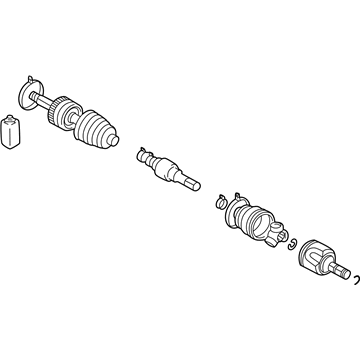

- Q: What Role Does the Axle Shaft Play in Front and Rear Axle Assemblies on Dodge Dakota?A:The rear axle assembly is a hybrid, semi-floating type with a casting differential carrier and pressed steel cover. The axle tubes are made of steel and pressed and welded into the carrier. An optional locking rear axle is available, which utilizes multi-disc clutch packs to lock both axleshafts together, providing equal rotational power to both wheels when one loses traction. On 4WD models, a fully independent front axle assembly is used, consisting of a differential, two axle shafts, and a pair of driveaxles with inner and outer Constant Velocity (CV) joints. To accommodate the offset differential, an extended axleshaft is employed on the right side. Before assuming an axle problem, a thorough check should be performed as noises commonly associated with axle diagnosis procedures can be caused by road surface, tire wear or pressure, or engine and transmission issues. Overhaul and general repair of the front or rear axle differential is beyond the scope of this description.

- Q: What role does the Axle Shaft play in supporting weight within the rear axle assembly on Dodge Ramcharger?A:The rear axle assembly is straight, hollow construction that includes a differential and axleshafts with the 'sprung' weight of a vehicle being supported from the axle housing and frame rails through the help of springs which can be leaf spring or coil spring types. They can be classified according to the extent of their floating as semi-floating and full-floating axleshafts, most of the truck models that have GVW below 7000 have semi-floating axleshafts or only the outer end floats while full-floating axleshafts do not even support any vehicle weight and can be removed without disturbing the wheel bearings. They both incorporate hypoid gears in which the centre line of the drive pinion is below that of the ring gear. Because of the absence of easy accessibility to most of these parts and tools, it is recommended that only limited work be done on these models; in cases where repairs or overhaul are needed, the axle assembly should be removed and delivered to a rebuilder or exchanged for a new or rebuilt unit since it is becoming more and more difficult to locate individual axle components for local repair work. Daily maintenance along with some simple repair works do not necessarily require the removal of the rear axle assembly and this includes; the axleshafts, hubs the wheel bearings, hub grease seals and the wheel lugs.

Related Dodge Parts

Browse Dodge Axle Shaft by Models

Charger Challenger Ram 1500 Dakota Durango Viper Dart Grand Caravan Ram 2500 Journey Caravan Avenger D100 D150 Magnum Neon Nitro Raider Caliber Ramcharger Dynasty Intrepid Ram 3500 Shadow Spirit Stratus Ram 50 W250 B250 B350 Charger Daytona D250 D350 Daytona Hornet Ram 1500 Van Sprinter 2500 Sprinter 3500 W100 W150 W350 B2500 B150 B1500 B3500 Ram 2500 Van Ram 3500 Van