JeepParts

My Garage

My Account

Cart

OEM Dodge A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

85 A/C Clutches found

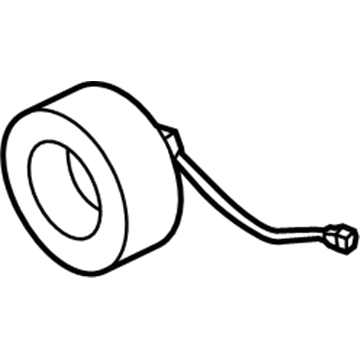

Dodge Clutch Coil Part Number: 68242651AA

$266.26 MSRP: $396.00You Save: $129.74 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil - A/C Clutch; A/C Compressor Clutch Coil; Coil; Coil A/C Clutch; A/C Compressor Clutch

- Replaces: 68058043AA, 68058043AC, 68058043AB

Dodge Clutch Assembly Part Number: 68166479AA

$39.06 MSRP: $58.10You Save: $19.04 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch; Clutch Plate & Hub Assembly; Clutch Overhaul Kit A/C Compressor

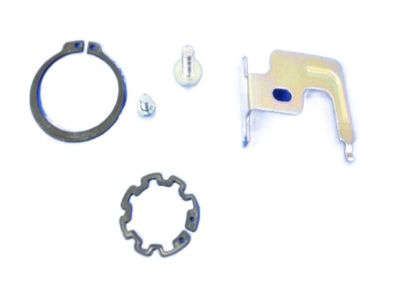

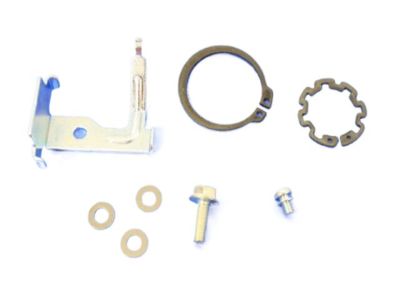

Dodge Clutch Kit Part Number: 5066228AA

$35.57 MSRP: $52.30You Save: $16.73 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch Drive Spacer; Repair Kit; Clutch; Clutch Overhaul Kit A/C Compressor; A/C Compressor Clutch

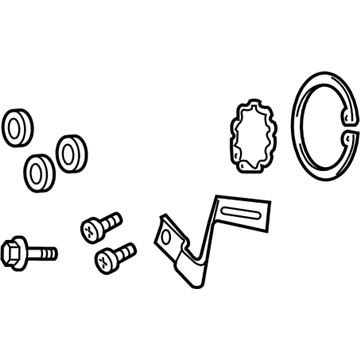

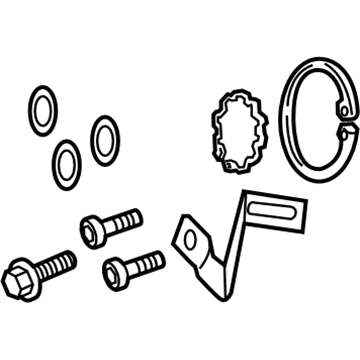

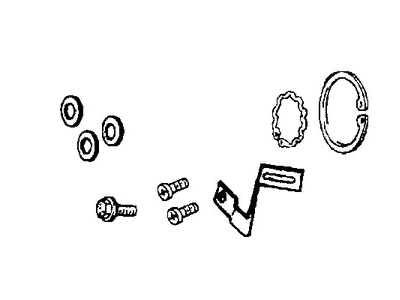

Dodge Clutch Kit Part Number: 68068755AA

$24.33 MSRP: $83.65You Save: $59.32 (71%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Repair Kit; A/C Compressor Clutch Overhaul Kit includes snap rings, washers, screws, and bolts.

- Replaced by: 68068755AB

Dodge Clutch Kit Part Number: 68232388AD

$279.57 MSRP: $423.00You Save: $143.43 (34%)Product Specifications- Other Name: Clutch - A/C Compressor; Repair Kit; Compressor Hardware Kit

- Replaced by: 68232388AE

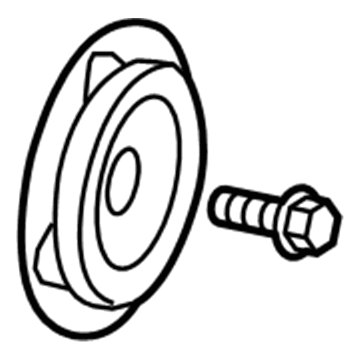

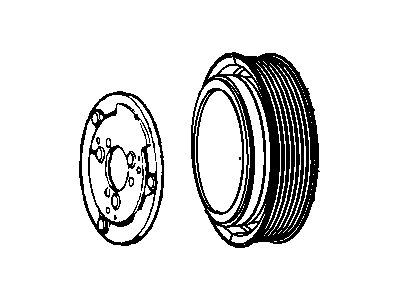

Dodge Pulley Part Number: 5140469AA

$49.81 MSRP: $63.15You Save: $13.34 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch; Pulley Hub Kit A/C Compressor

Dodge Clutch Coil Part Number: 5016127AB

$256.18 MSRP: $377.00You Save: $120.82 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch; Clutch A/C Compressor

Dodge Repair Kit Part Number: 5014572AA

$18.19 MSRP: $32.95You Save: $14.76 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; Shaft Seals; Overhaul Kit; Clutch Overhaul Kit A/C Compressor

Dodge Clutch Part Number: 68087443AC

$154.97 MSRP: $234.00You Save: $79.03 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Pulley

- Replaced by: 68087443AD

- Replaces: 68087443AA, 68087443AB

Dodge Compressor Clutch Part Number: 4723014

$122.41 MSRP: $155.18You Save: $32.77 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch; Serpentine Belt Drive Kit; Clutch & Pulley; Clutch Pulley; Pulley Assembly; Clutch Package, (Contains: Pulley And Bearing)

Dodge Clutch Kit Part Number: 5140428AA

$4.56 MSRP: $36.75You Save: $32.19 (88%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch; Hardware Kit; Clutch Overhaul Kit A/C Compressor with Snap Rings, Washers, Screws, Pulley Bolt.

Dodge Coil - A/C Clutch Part Number: 5140461AB

$122.73 MSRP: $257.00You Save: $134.27 (53%)Ships in 1-2 Business DaysProduct Specifications- Other Name: COIL-AIR CONDITIONING CLUTCH

Dodge Clutch Part Number: 68087441AC

$159.47 MSRP: $242.00You Save: $82.53 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Pulley

- Replaces: 68087441AA, 68087441AB

Dodge Clutch Coil Part Number: 68084275AB

$206.21 MSRP: $308.00You Save: $101.79 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil - A/C Clutch; A/C Compressor Clutch Coil; Coil A/C Clutch; A/C Compressor Clutch

- Replaces: 68084275AA

Dodge Pulley Assembly Part Number: 5135993AA

$184.18 MSRP: $233.48You Save: $49.30 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Serpentine Belt Drive Kit; Clutch; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

Dodge Clutch Part Number: 4762849

$102.04 MSRP: $129.36You Save: $27.32 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; Clutch A/C Compressor

Dodge Hub Assembly Part Number: 5179340AB

$299.82Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; A/C Compressor Clutch; Clutch Plate & Hub Assembly

- Replaces: 5179340AA

Dodge Clutch Part Number: 68045268AA

$34.03 MSRP: $50.05You Save: $16.02 (33%)Product Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch Overhaul Kit A/C Compressor Includes: Snap Rings, Shim Package, Pulley Bolt, Bracket, Screw

Dodge Clutch Part Number: 5189277AA

$46.05 MSRP: $58.38You Save: $12.33 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley - A/C Compressor; A/C Compressor Clutch; Pulley Hub Kit A/C Compressor

Dodge Hub Assembly Part Number: 68084834AC

$256.06 MSRP: $379.00You Save: $122.94 (33%)Product Specifications- Other Name: Pulley - A/C Compressor; A/C Compressor Clutch Pulley; Pulley Assembly; Clutch Plate & Hub Assembly; Pulley

- Replaces: 68084834AB, 68084834AA

| Page 1 of 5 |Next >

1-20 of 85 Results

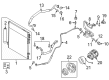

Dodge A/C Clutch

OEM parts sourced directly from Dodge deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Dodge A/C Clutch for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

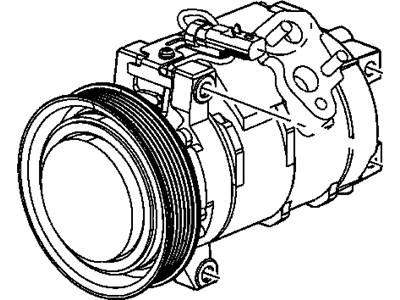

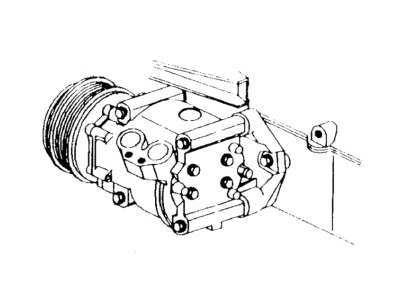

Dodge A/C Clutch snaps when needed to propel cold air that does not use engine power. Having been born in a cranky machine tool, Dodge cut a niche of steel bodies and crude strength. Decades later Dodge continued to churn out muscle machines, cramming HEMI powerplants under hoods that screamed to be put on the asphalt. With a 600-watt roar or hush like matching drag or stealth mode, the recent Fratzonic Chambered Exhaust pumps the brand. You can have donuts in the morning or a silent cruise home at sunrise and the same rebel spirit runs up and down every model. The noisy ideas do not rest on their laurels, and clattering gutsy ideas continue to pour out of the factory floor and onto the main street. That impatient disposition influences the paint colors with the mode of driving cars with a driver in control rather than an algorithm. Whether it is the horsepower or climate control, everything in a Dodge is important, and here is where accuracy begins. A/C Clutch is located at the nose of the compressor, waiting to receive a voltage pulse which closes the magnet and holds the pulley. A/C Clutch then rotates along with the belt; therefore, refrigerant rushes and cabin temperatures drop dramatically during hot days. As the alternating current switch is turned off, the drag is released immediately by A/C Clutch and horsepower is returned to the wheels. Tough and large enough to fit the entire line, A/C Clutch withstands heat and vibration and keeps the summer sweat at bay season after season. Trust in Dodge longevity that cycle continues one mile after another.

Dodge A/C Clutch Parts and Q&A

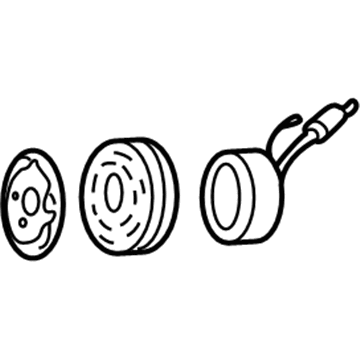

- Q: How to Install an A/C Clutch on Dodge Challenger?A:To install the clutch, line up the dowel pin on the compressor clutch field coil with the hole on the front of the compressor and set the field coil onto the compressor so the wire lead does not become pinched. The snap ring supplied with the compressor clutch field coil should be put on with the bevel outward and the two eyelets lining up on either side of the dowel pin. Put A/C Snap Ring Pliers 9764 or a similar tool to good use, placing the snap ring that holds the compressor clutch field coil into its groove. As you install the pulley and bearing unit, try not to harm the friction areas and use a new snap ring so the bevel edge is facing outside on the A/C compressor. If you use the old clutch plate and pulley and bearing assembly, replace the shim; if it's new equipment, install a stack of shims that are 2.54 mm thick. Put on the clutch plate on front of the A/C compressor and secure it by tightening the compressor shaft bolt until you reach 19 Nm. After you have tightened, test the air gap in various places to confirm it falls between 0.35 and 0.60 millimeters; do not hesitate to use shims if it isn't. Connect the lead from the compressor clutch field coil wire behind the bracket, attach the removable bracket and join the engine wire harness. After that, put in the accessory drive belt, secure the radiator fan, shroud assembly, air cleaner housing and air intake hose and connect the negative battery cable.

- Q: How to Maintain the A/C Clutch on Dodge Charger?A:Before beginning on the A/C compressor clutch, isolate the negative battery cable. Both 5.7L and 6.1L engine vehicles need you to remove their air intake hose and air cleaner housing during the process. After that, take out the radiator fan and shroud assembly, then take off the accessory drive belt. Remove the engine wire harness from the compressor clutch field coil connector found on the top of the A/C compressor. In a few models, you may need to take out the A/C compressor to handle the compressor shaft bolt or pulley and field coil snap rings and the refrigerant lines can stay fully pressurized throughout this work. Don't let the field coil or wire lead become attached to the connector bracket; separate it by hand. Getting rid of the compressor shaft bolt is possible if you hold the clutch plate from rotating with a band-type or strap wrench. Don't try to separate the clutch plate from the pulley and bearing assembly as this can ruin the clutch plate. Never lose any of the clutch shims while removing the clutch plate, since you can put them back in place during installation. Tap the clutch plate gently with a small plastic mallet to break them apart from the compressor shaft splines, then get rid of the clutch plate and any shim(s). Take the snap ring out at the front of the A/C compressor with A/C Snap Ring Pliers 9764 and use that grip to remove the pulley and bearing assembly as well. Finish by securing the A/C Snap Ring Pliers 9764 or the matching tool to the snaps that hold the clutch field coil against the front of the compressor and move the field coil to the side to remove it.

Related Dodge Parts

Browse Dodge A/C Clutch by Models

Charger Challenger Ram 1500 Dakota Durango Viper Dart Grand Caravan Ram 2500 Journey Caravan Avenger D150 Magnum Neon Stealth Ramcharger Dynasty Intrepid Ram 3500 Shadow Spirit Stratus W250 B250 B350 Colt D250 D350 Daytona Monaco Ram 1500 Van Sprinter 2500 Sprinter 3500 W150 W350 B2500 B150 B1500 B3500 Ram 2500 Van Ram 3500 Van