JeepParts

My Garage

My Account

Cart

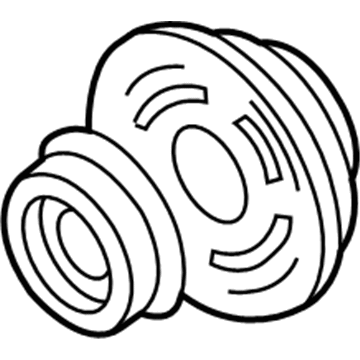

OEM Chrysler A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

56 A/C Clutches found

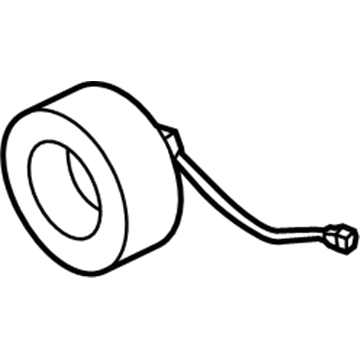

Chrysler Clutch Coil Part Number: 68242651AA

$266.26 MSRP: $396.00You Save: $129.74 (33%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Coil - A/C Clutch; A/C Compressor Clutch Coil; Coil; Coil A/C Clutch; A/C Compressor Clutch

- Replaces: 68058043AA, 68058043AC, 68058043AB

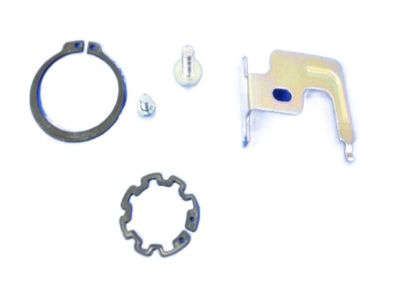

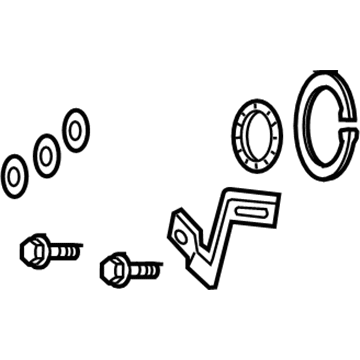

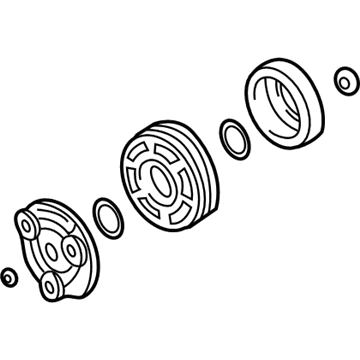

Chrysler Clutch Kit Part Number: 5066228AA

$35.57 MSRP: $52.30You Save: $16.73 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch Drive Spacer; Repair Kit; Clutch; Clutch Overhaul Kit A/C Compressor; A/C Compressor Clutch

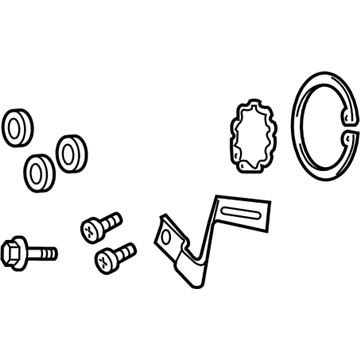

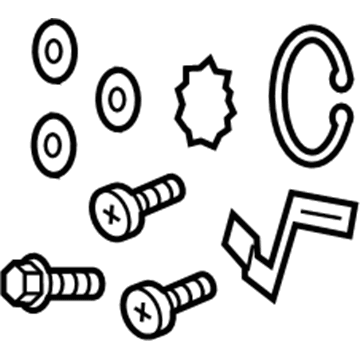

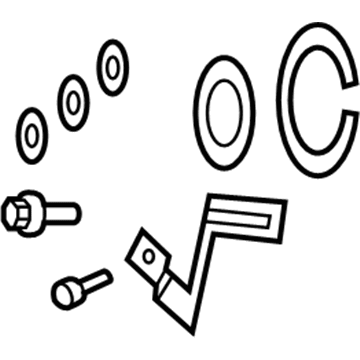

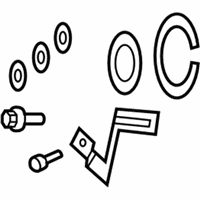

Chrysler Clutch Kit Part Number: 68068755AA

$24.33 MSRP: $83.65You Save: $59.32 (71%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Repair Kit; A/C Compressor Clutch Overhaul Kit includes snap rings, washers, screws, and bolts.

- Replaced by: 68068755AB

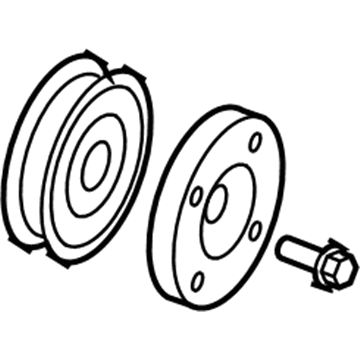

Chrysler Pulley Part Number: 5140469AA

$49.81 MSRP: $63.15You Save: $13.34 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch; Pulley Hub Kit A/C Compressor

Chrysler Repair Kit Part Number: 5014572AA

$18.19 MSRP: $32.95You Save: $14.76 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; Shaft Seals; Overhaul Kit; Clutch Overhaul Kit A/C Compressor

Chrysler Clutch Part Number: 68087443AC

$154.97 MSRP: $234.00You Save: $79.03 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Pulley

- Replaced by: 68087443AD

- Replaces: 68087443AA, 68087443AB

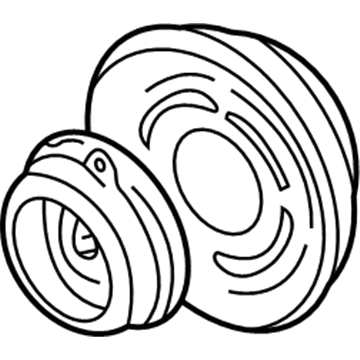

Chrysler Compressor Clutch Part Number: 4723014

$122.41 MSRP: $155.18You Save: $32.77 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch; Serpentine Belt Drive Kit; Clutch & Pulley; Clutch Pulley; Pulley Assembly; Clutch Package, (Contains: Pulley And Bearing)

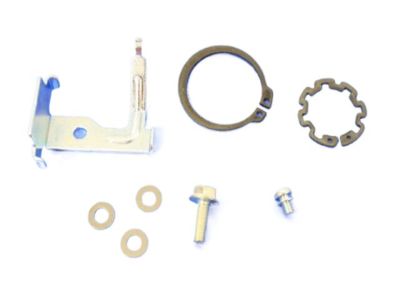

Chrysler Clutch Kit Part Number: 5140428AA

$4.56 MSRP: $36.75You Save: $32.19 (88%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch Package - A/C Compressor; A/C Compressor Clutch; Hardware Kit; Clutch Overhaul Kit A/C Compressor with Snap Rings, Washers, Screws, Pulley Bolt.

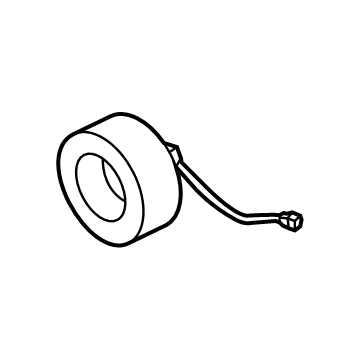

Chrysler Coil - A/C Clutch Part Number: 5140461AB

$122.73 MSRP: $257.00You Save: $134.27 (53%)Ships in 1-2 Business DaysProduct Specifications- Other Name: COIL-AIR CONDITIONING CLUTCH

Chrysler Clutch Part Number: 68087441AC

$159.47 MSRP: $242.00You Save: $82.53 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Pulley

- Replaces: 68087441AA, 68087441AB

Chrysler Pulley Assembly Part Number: 5135993AA

$184.18 MSRP: $233.48You Save: $49.30 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Serpentine Belt Drive Kit; Clutch; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

Chrysler Clutch Part Number: 4762849

$102.04 MSRP: $129.36You Save: $27.32 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; Clutch A/C Compressor

Chrysler Hub Assembly Part Number: 5179340AB

$299.82Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; A/C Compressor Clutch; Clutch Plate & Hub Assembly

- Replaces: 5179340AA

Chrysler Clutch Part Number: MR500339

$74.98 MSRP: $95.05You Save: $20.07 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch A/C Compressor

Chrysler Hub Assembly Part Number: 5140426AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Clutch Plate & Hub Assembly; Pulley; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

Chrysler Clutch Kit Part Number: 5066225AA

Product Specifications- Other Name: Clutch Kit - A/C Compressor; A/C Compressor Clutch; Repair Kit; Hardware Kit; Clutch; Clutch Overhaul Kit A/C Compressor

Chrysler Hub Assembly Part Number: 5179519AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Clutch Plate & Hub Assembly; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

Chrysler Hub Assembly Part Number: 68084834AC

$256.06 MSRP: $379.00You Save: $122.94 (33%)Product Specifications- Other Name: Pulley - A/C Compressor; A/C Compressor Clutch Pulley; Pulley Assembly; Clutch Plate & Hub Assembly; Pulley

- Replaces: 68084834AB, 68084834AA

Chrysler Hub Assembly Part Number: 5140425AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch Pulley; Clutch Plate & Hub Assembly; Pulley Hub Kit A/C Compressor; A/C Compressor Clutch

Chrysler Clutch & Pulley Part Number: 5014573AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch; Clutch; Pulley; Pulley Hub Kit A/C Compressor

| Page 1 of 3 |Next >

1-20 of 56 Results

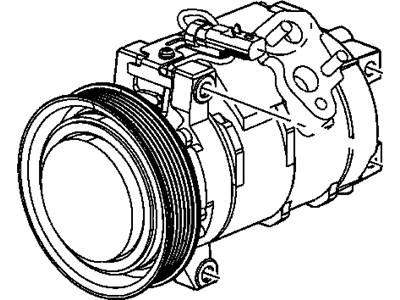

Chrysler A/C Clutch

OEM parts sourced directly from Chrysler deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Chrysler A/C Clutch for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

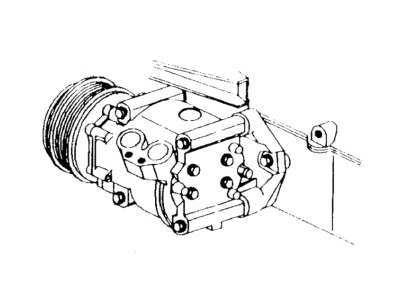

Chrysler A/C Clutch converts engine energy into instant cabin cooling that consumes no fuel. Chrysler has the credits of pushing the pioneer cars to smoother roads with the innovative Floating Power mounting module, a clever gimmick that controlled the vibration and allowed even the rocky roads to be courteous. Chrysler pursued more radical designs such as the sleek Airflow, skimming sheet metal and pushing radiators further aside to allow the wind to blow off the hood and silencing the inside. Next, Chrysler unveiled the first useful minivan, a demonstration that a non-blingy flat floor, broad doors, and straightforward charges work more effectively than the glittering gimmick in family consideration. Chrysler continues to fine-tune cabin expansion, seat relaxation, and ride adjustment, thus weekend journeys or commuting are not exhausting but calm. A/C Clutch is mounted on the compressor pulley and only takes engine torque when the dash switch requests cold air. A/C Clutch involves a magnetized hub to attach a rotating drum to the belt drive, locking it so that no slip will steal the cooling output, increase revs, and burn fuel during long trips. A/C Clutch stops as soon as cooling is not needed and the compressor is not subjected to unnecessary drag, and its life is prolonged many times beyond the challenging summers. A/C Clutch fits both four-cylinder and V6 engines in the entire lineup, which provides every driver with predictable chill without the additional hassle.

Chrysler A/C Clutch Parts and Q&A

- Q: How to Install an A/C Clutch on Chrysler 300?A:Place the back of the clutch field coil over the dowel pin and then, with the rear facing the compressor, line up the hole in the front of the clutch with the hole on the A/C compressor. A new snap ring needs to hold the compressor clutch field coil in place, with the bevel pointing out and the eyelets next to the correct side of the dowel pin. Using similar pliers, slide in the ring that holds the field coil, making certain it is properly in place. Don't engage the friction surfaces during pulley and bearing assembly installation and make sure the snap ring with bevel side outward helps secure it. In the case of using original pump parts, add back the original shims to the compressor shaft; for new parts, add trial shims measuring 2.54 mm each. Insert the clutch plate onto the A/C compressor and use the compressor shaft bolt to fix it in place. Make the bolt connection tight at 19 Nm. After you tighten each wheel, check the air gap at different places; if it isn't between 0.35 - 0.60mm, replace the shims as required. Lift the compressor clutch field coil wire lead behind the connector bracket, fit the connector into place and connect the engine wire harness. Install the drive belt on the accessories, then add the radiator fan and shroud assembly, air cleaner housing and air intake hose for 5.7L and 6.1L engine cars. Afterward, connect the negative battery cable again.

- Q: How to Maintain the A/C Clutch on Chrysler Town & Country?A:The first step is to take off and separate the negative battery cable before starting the service. Take out the air intake hose from both the air filter housing and the resonator, drain a little of the coolant and lift the upper radiator hose off the radiator. After that, unfasten the radiator fan and shroud, then the accessory drive belt. Take out the engine wire harness from the connector you find on the top of the A/C compressor. Relax the compressor clutch field coil from its connector bracket and detach the wire lead as well. To remove the compressor shaft bolt, keep the clutch plate from turning by holding it with a band-type oil filter wrench or strap wrench. Do not attempt to open space between the clutch plate and the pulley and bearing assembly to ensure the clutch plate is not damaged. Don't lose any clutch shims when you remove them, as you may need them again when installing. Tap the clutch plate lightly with a plastic mallet to separate it from the splines found on the compressor shaft. Afterward, remove both the clutch plate and any shims. Putting on A/C Snap Ring Pliers 9764 or similar, pull out the snap ring so that you can take the pulley and bearing assembly from the front of the A/C compressor. Lastly, take advantage of A/C Snap Ring Pliers 9764 or anything similar to unlock and remove the snap ring that holds the compressor clutch field coil to the front of the A/C compressor.