JeepParts

My Garage

My Account

Cart

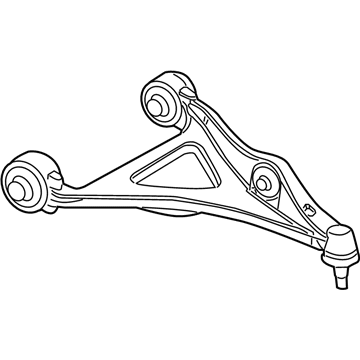

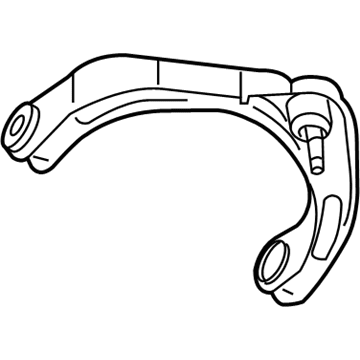

OEM Dodge Control Arm

Suspension Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

267 Control Arms found

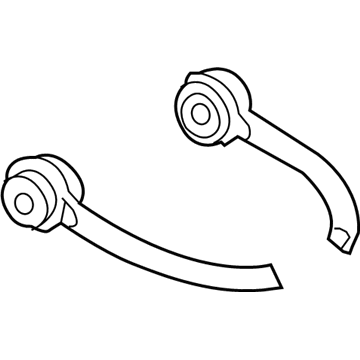

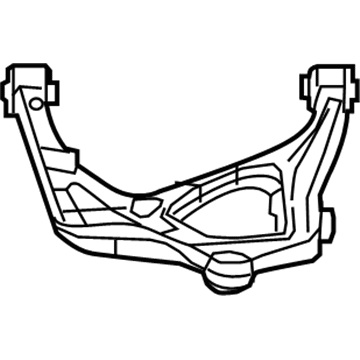

Dodge Upper Control Arm, Front Passenger Side Part Number: 68291036AB

$233.40 MSRP: $347.00You Save: $113.60 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm - Upper Control; Front Right Upper Suspension Control Arm and Ball Joint Assembly.; Arm Upper Control Front; Control Arm

- Position: Front Upper Passenger Side

- Replaces: 68291036AA

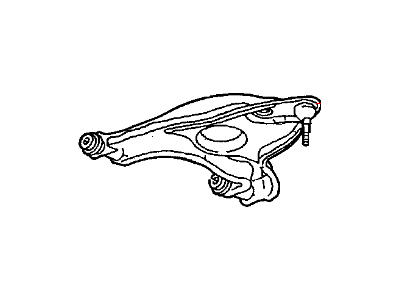

Dodge Lower Control Arm Part Number: 52038406

$402.36 MSRP: $510.07You Save: $107.71 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm - Lower Control; Suspension Control Arm and Ball Joint Assembly; Control Arm Assembly; Control Arm; Arm Lower Control Front; Arm, Control Lower; Arm Control

- Position: Lower

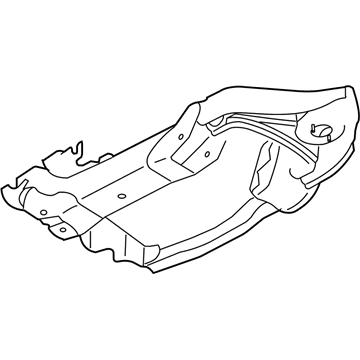

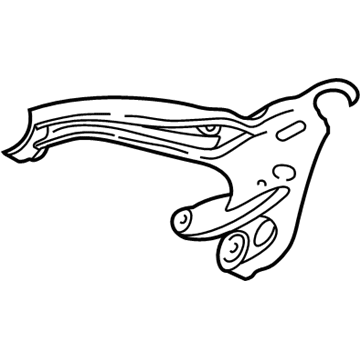

Dodge Lower Control Arm, Front Passenger Side Part Number: 68037500AC

$118.97 MSRP: $177.00You Save: $58.03 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm - Lower Control; Front Right Suspension Control Arm and Ball Joint Assembly.; Arm Lower Control Front Include Bushings; Control Arm

- Position: Front Lower Passenger Side

- Replaces: 55366484AD, 55366484AG, 55366484AB, 68037500AA, 55366484AE, 55366484AC, 68037500AB, 55366484AF, 55366484AH

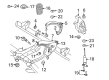

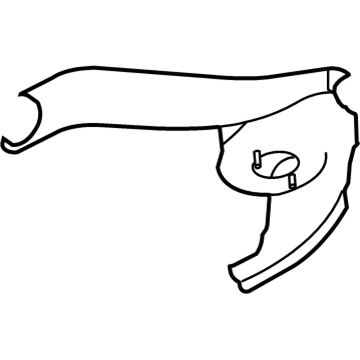

Dodge Lower Control Arm, Front Driver Side Part Number: 68211103AB

$335.40 MSRP: $755.00You Save: $419.60 (56%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Arm - Lower Control; Front Left Suspension Control Arm and Ball Joint Assembly.; Arm Lower Control Front; Control Arm

- Position: Front Lower Driver Side

- Replaces: 68211103AA

Dodge Lower Control Arm Part Number: 52038407

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm and Ball Joint Assembly; Control Arm Assembly; Control Arm; Arm Lower Control Front; Arm, Control Lower; Arm Control

- Position: Lower

Dodge Lower Control Arm, Front Passenger Side Part Number: 52106558AF

Product Specifications- Other Name: Arm - Lower Control; Front Right Lower Suspension Control Arm and Ball Joint Assembly.

- Position: Front Lower Passenger Side

- Replaces: 52106558AD, 52106558AE

Dodge Lower Control Arm, Front Driver Side Part Number: 52106559AF

Product Specifications- Other Name: Arm - Lower Control; Front Left Suspension Control Arm and Ball Joint Assembly.

- Position: Front Lower Driver Side

- Replaces: 52106559AD, 52106559AE

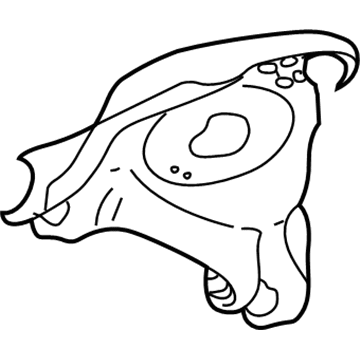

Dodge Lower Control Arm, Rear Driver Side Part Number: 52855382AA

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm, Rear Left Lower; Arm Lower Control Rear; Suspension Control Arm; Control Arm

- Position: Rear Lower Driver Side

Dodge Upper Control Arm, Front Part Number: 52855100AF

Product Specifications- Other Name: Arm - Upper Control; Front Upper Suspension Control Arm and Ball Joint Assembly.; Arm Upper Control Front; Control Arm

- Position: Front Upper

- Replaces: 52855100AC, 52855100AD, 52855100AE

Dodge Lower Control Arm Part Number: 52113888AB

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm and Ball Joint Assembly; Control Arm Assembly; Control Arm

- Position: Lower

Dodge Lower Control Arm Part Number: 52113889AB

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm and Ball Joint Assembly; Control Arm Assembly; Control Arm

- Position: Lower

Dodge Lower Control Arm, Rear Passenger Side Part Number: 52124810AF

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm, Rear Right Lower; Arm Lower Control Rear; Control Arm

- Position: Rear Lower Passenger Side

- Replaces: 52124810AC, 52124810AD, 52124810AE

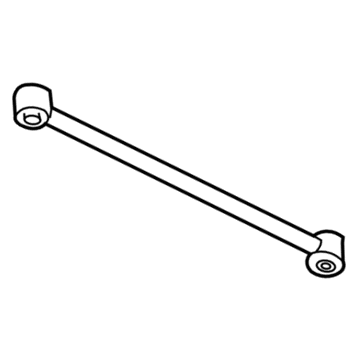

Dodge Lower Control Arm Part Number: 55366372AB

Product Specifications- Other Name: Arm - Lower Control; Control Arm

- Position: Lower

Dodge Lower Control Arm, Front Passenger Side Part Number: 5290614AE

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm, Front Right Lower; Control Arm

- Position: Front Lower Passenger Side

- Replaces: 5290614AD, 5290614AC, 5290614AB, 5290614AA

Dodge Lower Control Arm, Rear Driver Side Part Number: 52124811AF

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm, Rear Left Lower; Arm Lower Control Rear; Control Arm

- Position: Rear Lower Driver Side

- Replaces: 52124811AE, 52124811AC, 52124811AD

Dodge Lower Control Arm, Front Driver Side Part Number: 5290615AE

Product Specifications- Other Name: Arm - Lower Control; Suspension Control Arm, Front Left Lower; Control Arm

- Position: Front Lower Driver Side

- Replaces: 5290615AD, 5290615AA, 5290615AB, 5290615AC

Dodge Lower Control Arm Part Number: 5290560AD

Product Specifications- Other Name: Arm - Lower Control; Control Arm

- Position: Lower

- Replaces: 5290560AC, 5290560AB

Dodge Lower Control Arm, Front Driver Side Part Number: 5290561AD

Product Specifications- Other Name: Arm - Lower Control; Front Left Suspension Control Arm and Ball Joint Assembly.

- Position: Front Lower Driver Side

- Replaces: 5290561AC, 5290561AB

Dodge Lower Control Arm, Front Passenger Side Part Number: 52106560AE

Product Specifications- Other Name: Arm - Lower Control; Front Right Suspension Control Arm and Ball Joint Assembly.

- Position: Front Lower Passenger Side

- Replaces: 52106560AD

Dodge Lower Control Arm Part Number: 55366373AB

Product Specifications- Other Name: Arm - Lower Control; Control Arm

- Position: Lower

| Page 1 of 14 |Next >

1-20 of 267 Results

Dodge Control Arm

OEM parts sourced directly from Dodge deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Dodge Control Arm for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Dodge Control Arm ensures that wheels remain fixed in bumps that provide all the models with better handling and steering. Dodge began as a machine shop with no nonsense; it made news by introducing the first mass-produced all-steel body car in 1914 and debuting the original prototype as more durable than ornamental. Dodge continued to pound power ahead with raving HEMI blocks to the outrageous Viper that transformed lonely highways into rolling cauldrons to anyone who was bold enough to stick it to the floor on average plates. Dodge also electrifies swagger with the Fratzonic Chambered Exhaust, pumping a 600-watt blast in either the Drag, Donut, or Sport, but switching to hushed Stealth when neighbors are asleep. Dodge culture idolizes unrefined punch, not-so-subtle styling, the bang of exhaust note, and the notion that all commutes should have adrenaline over boredom. The Control Arm connects the chassis to the individual wheels using bushings, which allow the suspension components to slide over potholes without throwing the passengers around. Constructed of heavy cast iron or weight-reducing aluminum, the Control Arm opposes corner load, holds the toe and camber angles in place, and keeps rubber pressed on the road, making the braking force directly proportional to the stopping distance rather than vibration. A new Control Arm puts them back on track when the bushings crack or when ball joints relax and introduce the undisciplined wandering that grabs knuckles on long shots. The life of tires is also safeguarded by a correctly torqued Control Arm that does not cause camber drift when the car travels endless miles on the highway.

Dodge Control Arm Parts and Q&A

- Q: How to remove and install the lower control arm on Dodge Challenger?A:Before you attempt to take off the lower control arm you need to take off the front wheel, install a jack under the car and put on the frame rails, then unbolt the wheel lug nuts and raise the car. Second, remove the engine splash shield from under the car and then remove the stabilizer bar brackets for a view at the lower control arm-to-subframe mounting bolt. This bolt should have grooves and these are normally designed to make adjustments for the wheel alignment purposes. With the involved mounting bolt still in place, undo the nut and slow and cautiously pull out the bolt to its position in the notched position of the bushing. Go on and undo the shock absorber lower mounting bolts and nuts and unplug the ABS wheel speed sensor connector from the bracket. Hold the lower control arm steady by the lower control arm skit, then unscrew the balljoint nut up to the flat of the threaded stud only but do not remove it then use ball joint remover to detach the ball joint from the lower control arm. Upon the removal of the balljoint stud nut, force the knuckle down in order to detach it from the lower control arm to allow the lower control arm to be detached from the subframe bracket. For installation, lift the lower control arm with a floor jack to approximate normal ride height prior to tightening the mounting nut at the subframe, and the lower shock absorber fasteners. This should be done in reverse to the above steps, by replacing the balljoint stud nut with a new one, and ensuring that all nuts and bolts used are tighten to the recommended torque settings. Last of all, put back the wheel and the lug nuts; lower the car and tighten the lug nuts to the recommended torque; and get the front end alignment checked, and done if it is off.

- Q: How to remove and replace the lower control arm and its bushing on Dodge Ramcharger?A:Remove the coil spring. Next, take out the control arm mounting bolt from the crossmember and detach the lower control arm. If the bushing is worn, it can be pressed out and a replacement pressed in using a vise and sleeve. Installation is the reverse of removal, but avoid tightening the mounting bolt until the weight of the vehicle is on the suspension.

Related Dodge Parts

Browse Dodge Control Arm by Models

Charger Challenger Ram 1500 Dakota Durango Viper Dart Grand Caravan Ram 2500 Journey Caravan Avenger D100 D150 Magnum Neon Nitro Stealth Caliber Ramcharger Omni Dynasty Intrepid Ram 3500 Shadow Spirit Stratus W250 600 Aries B250 B350 Charger Daytona Colt D250 D350 Daytona Hornet Ram 1500 Van Rampage Sprinter 2500 Sprinter 3500 W100 W150 W350 B2500 Lancer B150 B1500 B3500 Ram 2500 Van Ram 3500 Van