JeepParts

My Garage

My Account

Cart

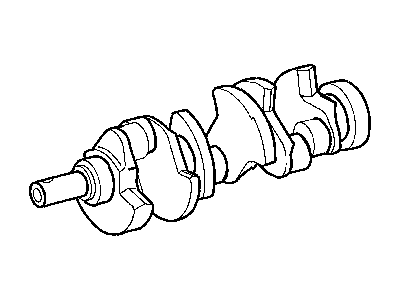

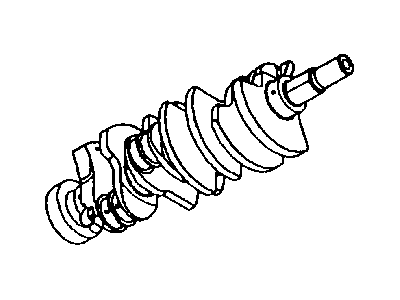

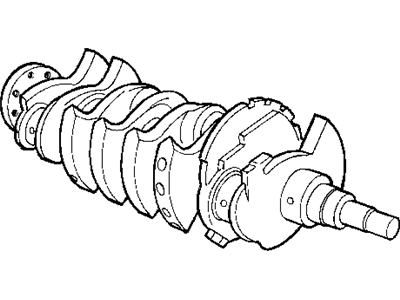

OEM Chrysler Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

32 Crankshafts found

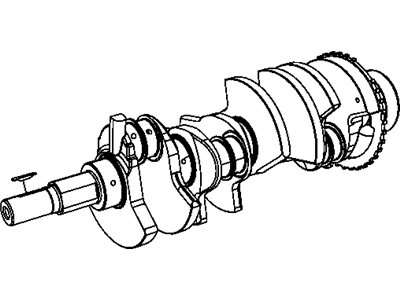

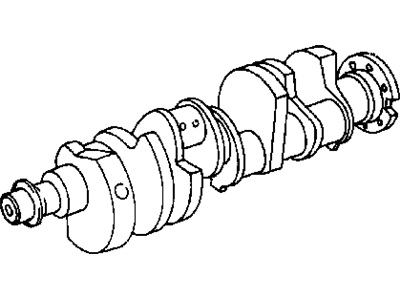

Chrysler Crankshaft Part Number: 53021302BC

$833.71 MSRP: $1105.00You Save: $271.29 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

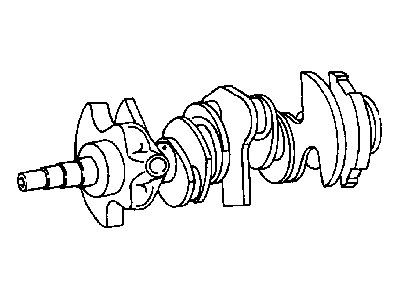

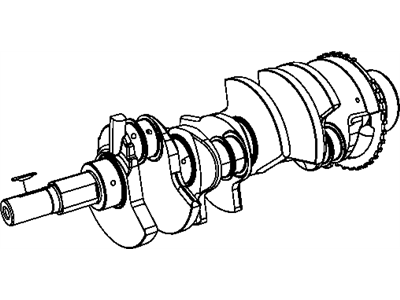

Chrysler Crankshaft Part Number: 4792333

$121.61 MSRP: $154.16You Save: $32.55 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

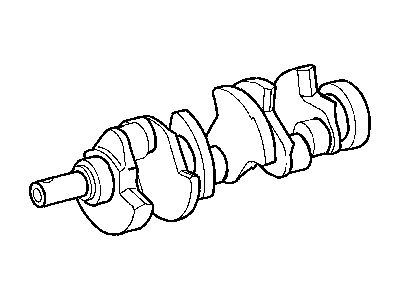

Chrysler Crankshaft Part Number: 5097107AA

$715.31 MSRP: $2270.00You Save: $1554.69 (69%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

- Replaces: 5097109AA

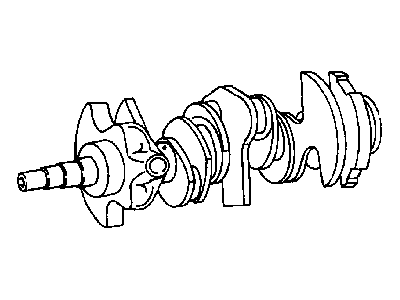

Chrysler Crankshaft Part Number: 5143037AA

$2082.79 MSRP: $2640.31You Save: $557.52 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

Chrysler Crankshaft Part Number: 5159230AA

$76.27 MSRP: $96.69You Save: $20.42 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

Chrysler Crankshaft Part Number: 53021302BB

$215.27 MSRP: $317.00You Save: $101.73 (33%)Product Specifications- Other Name: Crankshft; Crankshaft See Note

Chrysler Crankshaft Part Number: 5037458BD

Product Specifications- Other Name: Crankshft

- Replaces: 5037458AB, 5037458AC, 5037458AA

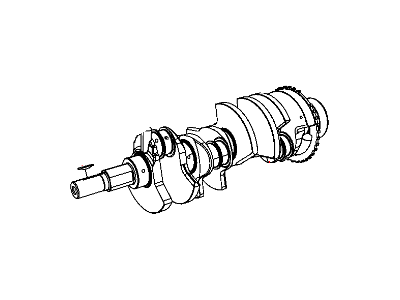

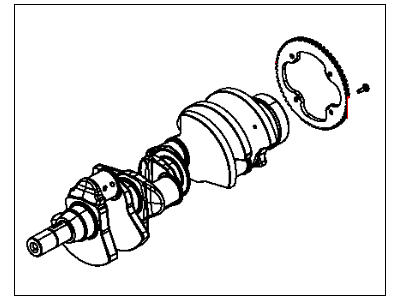

Chrysler Crankshaft Part Number: 53021302AD

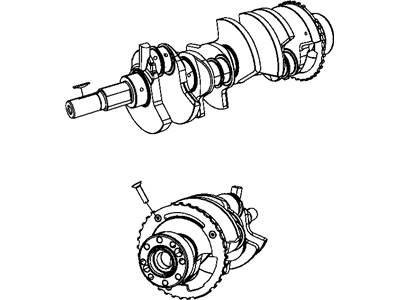

Product Specifications- Other Name: Crankshft; Crankshaft Includes Tone Ring And Tone Ring Mounting Screws

Chrysler Crankshaft Part Number: 53022286AA

Product Specifications- Other Name: Crankshft; Crankshaft See Note

Chrysler Crankshaft Part Number: 68641994AA

$554.18 MSRP: $814.00You Save: $259.82 (32%)Chrysler Crankshaft Part Number: 4792176

Chrysler Crankshaft Part Number: 53021387AA

Product Specifications- Other Name: Crankshft

Chrysler Crankshaft Part Number: 68293005AB

$1015.62 MSRP: $1505.00You Save: $489.38 (33%)Product Specifications- Other Name: Crankshft

- Replaces: 5038339AC, 68293005AA

Chrysler Crankshaft Sensor Part Number: 4556224

Product Specifications- Other Name: Crankshaft; Crankshaft Assembly

Chrysler Crankshaft Part Number: 4621917

Product Specifications- Other Name: Crankshft; Crankshaft, Machined

Chrysler Crankshaft Part Number: 68001694AC

Product Specifications- Other Name: Crankshaft - Engine; Crankshaft Kit Engine See Note; Crankshaft Package Engine; Crankshaft Kit Engine

- Replaces: 68001694AA, 4884563AC

Chrysler Crankshaft Part Number: 68002690AA

Product Specifications- Other Name: Crankshaft - Engine; Crankshaft Package Engine See Note; Crankshaft Kit Engine See Note; Crankshaft Package Engine

Chrysler Crankshaft Part Number: 4483196

Product Specifications- Other Name: C/Shaft - Finish Machine; Crankshaft , (Except Edr Turbo - Intercooler)

Chrysler Crankshaft Part Number: 4343423

Product Specifications- Other Name: Crankshaft-2.2 Turbo Light Weight

Chrysler Crankshaft Part Number: 4792692AB

Product Specifications- Other Name: Crankshft

- Replaces: 4792692AC, 4792177, 4792692AA

| Page 1 of 2 |Next >

1-20 of 32 Results

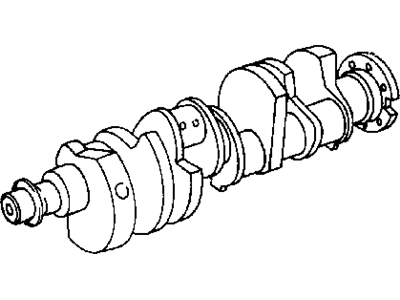

Chrysler Crankshaft

OEM parts sourced directly from Chrysler deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Chrysler Crankshaft for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

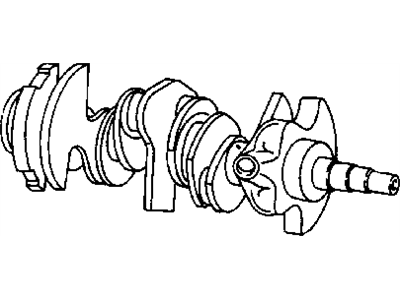

Chrysler Crankshaft converts the brash piston driving power into flowing rotary energy, chopping out vibration and allowing each engine to breathe easier. In 1925, Chrysler expanded its name through the construction of sound cars that could be purchased by ordinary families without any sense of being cheated. Chrysler made Floating Power mounts to absorb engine vibration, and the forbearing Airflow body forced the wind off to maintain cabins quiet and fresh on long road days. This would later be followed by Chrysler, who introduced the first practical minivan, which in space, easy access and straightforward pricing won over flashy gimmicks every weekend. The drivers are still aware that there are spacious interiors, comfortable rides and utility, designed not to act like showroom drama. The Crankshaft is heavily loaded and made to withstand the inhuman loads, and it is necessary to spin under the precise micrometer control with the high revs. Chrysler aligns the Crankshaft to engine torque curves and the commuters can cruise and haulers can pull without rattles or thirsty reroutes. Since the Crankshaft ensures the mass remains centered, the entire powertrain becomes durable, less noisy and confident in its ability to move big weight on steep grades. Oil change every now and then makes the Crankshaft film tough preventing metal to metal scars before they begin.

Chrysler Crankshaft Parts and Q&A

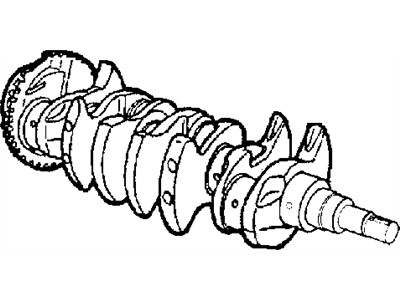

- Q: How to install a crankshaft during engine reassembly on Chrysler Cirrus?A:Crankshaft installation comes immediately after dismantling of the engine with the assumption that the engine block and crankshaft need to be cleaned, inspected and repaired if necessary. Rotate the engine block so that its bottom end is up and extract the mounting bolts to send the main bearing cap assembly a trip to the junkyard. If possible, the original bearing inserts should be taken out from the block as well as the main bearing cap assembly and the bearing areas should be cleaned in order to accurately take the measurement of oil clearance. Machine all the new upper main bearing inserts bright and fit one in each main bearing saddle so the oil holes coincide. The thrust bearing insert or thrust washers must be fitted in the No. 3 bearing position with the grooving on the side of the crankshaft. The back sides of the lower main bearing inserts must be cleaned and then installed in the main bearing cap assembly without having to apply any lubrication, to fit properly. Scrub the faces of the bearing insert bores and crankshaft main bearingFDA journal bores, and get to note if the oils fholes are plugged by dirt FDA . After you have accomplished cleaning the crankshaft, position the crankshaft on the cylinder block of the car and ensure that if it is a 4 cylinder engine then the crankshaft position sensor has been taken out. For 2.0L engines, make sure that locating dowels are there to give the engine a right alignment. Take small strips of Plastigage and lay it down on each Crankshaft main bearing journal; clean the bearing insert faces in the main bearing cap assembly and fit it in place without removing the Plastigage. Use clean engine oil applying it to all bolt threads before installing them, while tightening the main bearing cap assembly bolts in order without turning the crankshaft. Loosen and take out the bolts in the reverse sequence and raise the main bearing cap assembly away and to compare the crushed Plastigage width to the scale to give oil clearance. If the clearance is too large, search for dir or oil interfering and if necessary, replace the bearing Inserts. Gently remove any more Plastigage, then raise the crankshaft and clean up the bearing insert flanks on the cylinder block-you might use a little moly-base grease or engine assembly lube here. Put a new oil filter passage O-ring seal for the 2.0 L engines and check whether the dowel are inserted or not. Remove the main bearing cap assembly and clean their mating surfaces, apply a bead of anaerobic sealer to the cylinder block foam. Place the crankshaft again in its position, than clean the faces of the bearing insert in the main bearing cap assembly, the application of the lubricant should not be in the mating surface. The main bearing cap assembly should bear on locating dowels and all the bolt threads of the caps should be lubricated with clean engine oil before they are tightened. A specific sequence of tightening is applied to the bolts of the 2.0L engines, while thrust bearing alignment must be done correctly in 2.4L engines and tighten them. For the V6 engines, the bolts are tightened in a sequence that is recommended according to an authorized manual then, lightly strike the crankshaft in the area of the main bearing and thrust faces. Spin the crankshaft and have the bearing caused binding; the crank shaft should rotate with an effort of 50 in-lbs or less; re-check the amount of crankshaft end play. Last of all, replace the new rear main oil seal.

- Q: How to remove Crankshaft on Chrysler Imperial?A:The crankshaft can only be removed after the engine has been taken out of the vehicle, assuming that the flywheel or driveplate, crankshaft balancer/vibration damper, timing chain or belt, oil pan, oil pump, counterbalance shafts (if equipped), and piston/connecting rod assemblies have already been detached. Before removal, check the endplay by mounting a dial indicator with the stem aligned with the crankshaft, touching one of the crank throws. Push the crankshaft to the rear and zero the dial indicator, then pry it to the front and check the reading; the distance moved indicates the endplay. If it exceeds the specified value, inspect the crankshaft thrust surfaces for wear, and if no wear is found, new main bearings should resolve the issue. If a dial indicator is unavailable, feeler gauges can be used by prying or pushing the crankshaft to the front and slipping the gauges between the crankshaft and the thrust main bearing to measure clearance. Check the main bearing caps for markings indicating their locations, which should be numbered consecutively from front to rear; if not, mark them with number stamping dies or a center-punch, ensuring to make the punch marks near one of the bolt heads. Main bearing caps typically have a cast-in arrow pointing to the front of the engine. Loosen the main bearing cap bolts gradually until they can be removed by hand, noting any stud bolts for proper reinstallation. Gently tap the caps with a soft-face hammer to separate them from the engine block, using the bolts as levers if necessary, and take care not to drop the bearing inserts. Finally, carefully lift the crankshaft out of the engine, ideally with assistance due to its weight, and with the bearing inserts in place, return the caps to their respective locations on the engine block and tighten the bolts finger tight.