JeepParts

My Garage

My Account

Cart

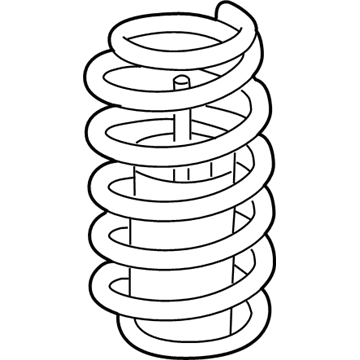

OEM Dodge Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

972 Coil Springs found

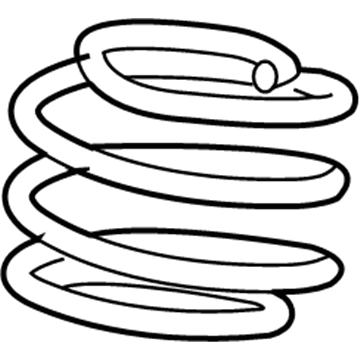

Dodge Coil Spring, Rear Part Number: 5168900AC

$128.23 MSRP: $194.00You Save: $65.77 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring; Spring Rear Coil

- Position: Rear

- Replaces: 5168900AA, 5168900AB

Dodge Coil Spring, Front Part Number: 4670575AA

$113.73 MSRP: $172.00You Save: $58.27 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

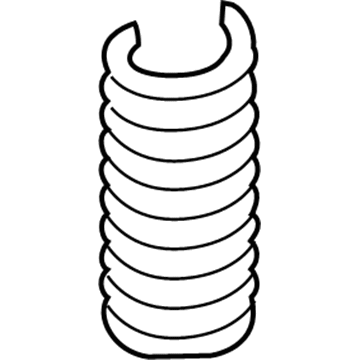

Dodge Spring, Front Part Number: 52106602AA

$52.99 MSRP: $67.18You Save: $14.19 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Spring Kit Front; Coil Spring Set; Coil Springs; Spring Front Coil

- Position: Front

Dodge Spring, Rear Part Number: 68042804AB

$142.72 MSRP: $216.00You Save: $73.28 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring Rear Coil

- Position: Rear

- Replaces: 68042804AA

Dodge Coil Spring, Rear Part Number: 68042803AB

$142.72 MSRP: $216.00You Save: $73.28 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring; Spring Rear Coil

- Position: Rear

- Replaces: 68042803AA

Dodge Coil Spring, Front Part Number: 68050562AA

$210.76 MSRP: $296.00You Save: $85.24 (29%)Product Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

Dodge Coil Spring, Front Part Number: 68531297AA

$83.29 MSRP: $127.00You Save: $43.71 (35%)Product Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

- Replaces: 5181500AB, 5181500AA, 68306123AA

Dodge Spring, Front Part Number: 52121804AA

$194.09 MSRP: $274.00You Save: $79.91 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring Front Coil

- Position: Front

Dodge Spring, Front Part Number: 52121803AA

$203.83 MSRP: $270.00You Save: $66.17 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring Front Coil

- Position: Front

Dodge Coil Spring, Front Part Number: 5168870AC

$65.39 MSRP: $147.00You Save: $81.61 (56%)Product Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

- Replaces: 5168870AA, 5168870AB, 68031648AB

Dodge Coil Spring, Rear Part Number: 4670588AB

$114.85 MSRP: $174.00You Save: $59.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring; Spring Rear Coil

- Position: Rear

- Replaces: 4670588AA

Dodge Coil Spring, Front Part Number: 5105854AE

$65.58 MSRP: $146.00You Save: $80.42 (56%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

- Replaces: 5105854AD, 5105854AA, 5105854AB, 5105854AC

Dodge Coil Spring, Front Part Number: 68531295AA

$80.89 MSRP: $124.00You Save: $43.11 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

- Replaces: 68306121AA

Dodge Coil Spring, Front Part Number: 68235724AC

$60.99 MSRP: $133.00You Save: $72.01 (55%)Product Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

- Replaces: 68235724AB, 68235724AA

Dodge Coil Spring, Rear Part Number: 5168037AC

$74.93 MSRP: $115.00You Save: $40.07 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring; Spring Rear Coil

- Position: Rear

- Replaces: 5168037AA, 5168037AB

Dodge Spring, Front Part Number: 55366475AA

$135.43 MSRP: $171.68You Save: $36.25 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring Front Coil

- Position: Front

Dodge Coil Spring, Rear Part Number: 68142534AA

$84.74 MSRP: $129.00You Save: $44.26 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring; Spring Rear Coil

- Position: Rear

Dodge Coil Spring, Front Part Number: 68507087AA

$120.42 MSRP: $182.00You Save: $61.58 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring; Spring Front Coil

- Position: Front

- Replaces: 5168207AA, 5168207AB, 68333764AA

Dodge Spring, Front Part Number: 52122725AA

$114.85 MSRP: $174.00You Save: $59.15 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Spring - Front Coil; Coil Spring, Front; Coil Springs; Spring Front Coil

- Position: Front

Dodge Coil Spring, Rear Part Number: 68066365AB

$84.07 MSRP: $126.00You Save: $41.93 (34%)Product Specifications- Other Name: Spring - Rear Coil; Coil Spring, Rear; Coil Springs; Spring; Spring Rear Coil

- Position: Rear

- Replaces: 68066365AA

| Page 1 of 49 |Next >

1-20 of 972 Results

Dodge Coil Springs

OEM parts sourced directly from Dodge deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Dodge Coil Springs for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

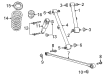

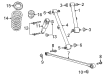

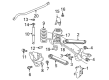

Dodge Coil Springs ensure that all Dodge models ride on any level over the bumps and resist squat, roll, and dive. Dodge began as a rough machine shop long before cars dominated the avenues and in a very short time established a legend of all-steel toughness and ruthless power in Detroit smoky foundries and in dusty proving grounds everywhere. In 1914, Dodge challenged convention with an all-steel body and was shown to be strong enough to endure longer than superfluous trimmings in the actual work of those who needed machines to withstand daily abuse. It then crammed the roads with HEMI thunder, Viper venom, and now the wild Fratzonic scream that lets even electric muscle scream on command as it revered the blue-collar heritage that made the cars a symbol of honest muscle. Dodge manufactures cars that are made to suit drivers whose needs are to accelerate, unapologetic design, and drive modes that can go from silent in the stealth mode to tire-smoking mayhem at any given time without watering down the raw edge or historic legacy. Coil Springs shoulder sets vehicle weight, compress over potholes, and rebound quickly, thus wheels remain in place and cabins remain comfortable without passengers or heavy cargo loads causing them to sag. There are linear, progressive, and dual rate allowing different drivers to adjust ride firmness to city commuting, highway driving, enthusiastic canyon driving, and weekend track driving. Coil Springs roll the body of the car, sharpen steering, and operate dampers to avoid bottoming as the car moves with loaded gear or over rough roads. The use of Coil Springs is long lasting when tempered as they do not fatigue easily, therefore maintaining the ride quality as one covers the miles.

Dodge Coil Springs Parts and Q&A

- Q: How to remove rear Coil Springs on a Dodge Ram 1500?A:Lift the vehicle and support it firmly on jackstands, then place another jack underneath the rear axle to hold up its weight. Unscrew the bolt from the lower shock absorber mount and slowly put down the jack until the spring and insulator can be removed. To reinstall, switch the removal steps going from the last step to the first step, tightening all fasteners.